Coronavirus Technology Solutions

May 14, 2020

Masks for Everyone Who Ventures

Outside Each Day

The Coronavirus may Become

Endemic like HIV

Berry Installing New Meltblown

Line in Berlin

Nursing Homes are Starting to

Incorporate HEPA Filters and

Antimicrobial Coatings

UV Light for Jails and Nursing

Homes

Washington State Dental Office

will Open with New Air Filters.

Northwestern Professor looking

at Chemically Treated Masks to

Destroy Viruses

Ben Gurion University

Researching the Potential for

Electrically Charged Graphene

Graphene also being pursued by

Hong Kong Polytechnic

Carbon Nanotubes are Another

Option

Masks with Copper Technology

Offered by Multiple Companies

___________________________________________________________________________

Masks for Everyone Who Ventures

Outside Each Day

The expert opinion on the value

of masks to fight COVID is

nearly the opposite of what it

was earlier in the year. Studies

show that nations which require

people to wear masks do much

better than those who do not.

The deaths per capita in the

U.S. are 70 times greater than

China. Because of air pollution

China has a long history of mask

wearing. Japan never shut down

but has a low death rate. The

reason is that the wearing of

masks is universal.

The latest discoveries are that

a significant fraction of the

virus travels in small aerosols

similar in size and mobility to

cigarette smoke.

A surgical mask may stop the

larger droplets caused by

sneezing and coughing but not

ones being exhaled. These small

smoke sized particles will

penetrate a surgical mask. It

would therefore be highly

desirable for everyone to wear

an N95 mask or one with

equivalent or even higher

efficiency.

To achieve this we need to

expand mask and filter media

production. We also need to

improve ways to decontaminate

and reuse masks. H2O2

decontamination methods could

potentially allow a mask to be

reused 10 to 20 times.

Simple mask washing is

the answer for masks made with

nanofibers and

membranes. They

presently account for a

small share of the market. Most

face masks use meltblown media.

McIlvaine predicts that the new

media technologies will

eventually dominate the market.

This will allow individuals to

wash their own masks and not

rely on a decontamination

vendor.

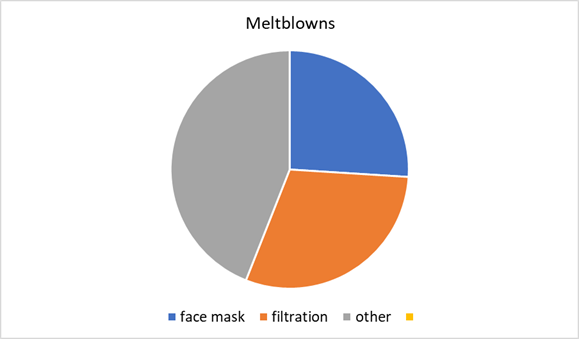

At present meltblown media is

used in most surgical and N95

masks. Meltblown media is also

used in air filters where the

demand is rising rapidly due to

COVID. Together these uses

account for a large portion of

the total.

Face

masks presently account for just

over one fourth of the meltblown

market.

Filtration is a large

application and incudes liquid

filtration, gas filtration,

cartridge filters, and air

filtration for HVAC and

cleanrooms where high efficiency

is required. COVID will increase

the need for meltblowns for air

filters in nursing homes,

apartment buildings,

restaurants, meat processing

plants and many other

establishments where people

congregate. So facemask and

filtration demands will compete

for the limited supply.

Cummins/Dupont are using filter

media normally used in engine

filters for facemasks. The

filtration segment also includes

oil adsorbents.

The

“other” segment includes medical

fabrics such as disposable

gowns, drapes and sterilization

wraps.

Reusable gowns are an

option which would reduce

meltblown demand. Meltblown

fabrics are used frequently in

feminine sanitary napkins,

diaper top sheets and disposable

adult incontinence products.

Also

included in the “other” segment

are disposable

industrial apparel, thermal

insulation and substrates for

synthetic leather. Meltblown

fabrics are sometimes used in

battery separators and as

insulation in capacitors.

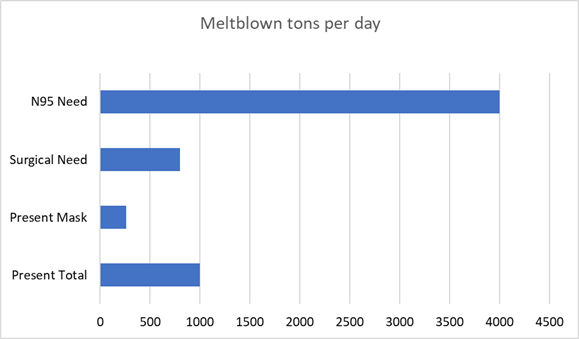

If half of the world’s 8 billion

people should be wearing N95

masks and these masks are reused

five times then 800

million masks need to be

produced each day.

N95 masks utilize more meltblown

media than do surgical masks.

|

Mask Production per ton per day of Meltblown Production |

|

|

Mask Type |

Number of masks per ton per day |

|

Surgical |

1 million |

|

N95 |

0.2 million |

World meltblown capacity was

1000 tons per day in January of

this year and has increased as

much as 10 percent over the last

six months.

|

Segment |

Tons per day Meltblown |

Potential # of Surgical Masks per day |

Potential # of N95 Masks per day |

|

Meltblown world capacity as of Jan 2020 |

1000 |

1 billion |

200 million |

|

Sinopec (either or) |

18 |

18 million |

3.6 million |

|

3M 2019 |

15 |

|

3 million |

|

3M 2020 |

30 |

|

6 million |

|

3M 2021 |

60 |

|

12 million |

|

*China 2020-April |

200 |

200 million |

? |

|

China-2020 Jan |

3 |

|

600,000 |

|

World needs -100% N95 |

4,000 |

|

800 million |

|

World needs -100% surgical |

800 |

800 million |

|

*Includes

non meltblown media

Mask production has grown by

triple digits in the last six

months but is not nearly enough

to supply each individual around

the world who congregates with

others each day.

The production of melt blown

media to fulfill the needs of

each person using N95 masks and

replacing them after five uses

would be 4000 tons per day.

This is four times the

meltblown production at the

start of 2020 and more than 15

times the present meltblown

capacity devoted to masks.

However the total is

small compared to the 41,000

tons per day of non wovens

produced for all applications.

So with less than 10 percent

increase in total non wovens

production the media for N95

masks for everyone who ventures

outside each day could be

achieved.

Masks are one of the elements

needed for a safe return to the

new normal.

The

Coronavirus may Become Endemic

like HIV

During a media briefing in

Geneva, Dr. Mike Ryan, executive

director of the WHO's health

emergencies program, warned

Wednesday that the disease may

join the mix of viruses that

kill people around the world

every year.

"This virus just may become

another endemic virus in our

communities and this virus may

never go away. HIV hasn't gone

away," Ryan said. "I'm not

comparing the two diseases but I

think it is important that we're

realistic. I don't think anyone

can predict when or if this

disease will disappear.

"We

may have a shot at eliminating

this virus but that vaccine will

have to be available, it will

have to be highly effective, it

will have to be made available

to everyone and we'll have to

use it," Ryan said. "This

disease may settle into a

long-term problem or it may

not."

WHO

infectious disease

epidemiologist Dr. Maria Van

Kerkhove struck a more

optimistic tone during

Wednesday's briefing."The

trajectory of this outbreak is

in our hands," Van Kerkhove

said. "The global community has

come together to work in

solidarity. We have seen

countries bring this virus under

control. We have seen countries

use public health measures."

Berry Installing New Meltblown

Line in Berlin

Berry Global Group, Inc. announced

the continued expansion of its

global Meltex™ meltblown

capacity, with the addition of

another asset to support the

growing global face mask demand.

This announcement comes as

demand surges due to COVID-19

and the increased need for

nonwoven protection materials.

The new asset is expected to be

operational in October 2020 and

will be placed in Europe at

Berry’s existing production

facility in Berlin, Germany and

will incorporate Berry’s

patented charging technology

post installation. The new line

will focus on the production of

highly efficient filter material

for premium FFP2 (N95) and FFP3

(N99) grade filter media.

“We are now beginning to see the

localization of varying forms of

equipment that produce materials

for PPE, as countries and

governments look to be able to

react with speed to any future

outbreaks,” said Cedric Ballay

EVP & GM for Europe in Health,

Hygiene, and Specialties at

Berry. “We continue to provide

timely solutions to those

looking for assistance fighting

the spread of COVID-19.”

As the largest manufacturer of

nonwoven fabrics, Berry makes

materials for the world’s

leading and emerging brands.

These products range in use from

materials for face masks,

respirators and protective

healthcare apparel to packaging,

many of which have been deemed

essential in the efforts to

fight the spread of COVID-19.

Nursing Homes are Starting to

Incorporate HEPA Filters and

Antimicrobial Coatings

Nursing homes have been

vulnerable to COVID for

multiple reasons. They

include shortages of safety gear

and staff workers who may

inadvertently be carriers and

the design of the buildings.

With shared resident rooms off

long corridors and dining rooms

where everyone mingles, nursing

homes may have been laid out to

be efficient and cost effective.

Since the country’s first

sizable outbreak in a

nursing home in Kirkland, Wash.,

the coronavirus has made its way

into 7,500 long-term care

facilities, killing dozens at

some. Across the country, more

than 143,000 of their residents

and workers have contracted the

illness and more than 25,600

have died, according to

a New

York Times analysis.

That is more

than a third of the deaths from

the pandemic.

Many of the 15,400 nursing

homes across the country

are laid out like hospitals, and

some house hundreds of

residents. Most rooms are double

occupancy, but some have three

or even four residents.

Before the pandemic, a movement

under the banner of “culture

change” was challenging this

institutional model, calling for

dividing up large nursing home

populations into small,

self-sufficient units with

kitchens, private rooms and a

dedicated staff.

Households with private rooms

take up about 10 percent more

space than conventional

interiors with shared rooms and

cost $15,600 more per bed, said

Perkins Eastman, an architecture

firm with an active health care

facility practice.

The

cost of building a skilled

nursing facility in the last 10

years ranged from $223 to $361

per square foot, according to

data based on an index of 100

cities compiled by the National

Investment Center for seniors

and Housing Care, one of the

main data service providers for

the elder care industry.

So

far, an estimated 10 to 15

percent of nursing homes in the

United States are set up this

way. This smaller-is-better

approach arose out of a concern

for residents’ privacy and

dignity, but evidence is

emerging that it may also be

helping with infection control.

A

private room or even an entire

household can be closed off more

easily, keeping out or confining

viruses. Staff members who are

focused on a small number of

residents may be more likely to

pick up on warning signs, such

as a lack of appetite, that

someone is sick. The preparation

of food and laundry in a

household — rather than in

central facilities and then

distributed — also eliminates a

few of the ways diseases can

infiltrate.

The Department of Veterans

Affairs began embracing

a small-house model in 2011;

now, 13 of its 134 nursing homes

are organized around communities

of 10 to 14 residents. In these

settings, only a single veteran

has tested positive for

Covid-19, Christina Noel, a V.A.

spokeswoman, said in a

statement.

Private rooms have made a “huge”

difference in the ability to

control the virus at Jewish

Senior Services, a four-story

building for skilled nursing and

assisted living in Bridgeport,

Conn., said Andrew H. Banoff,

president and chief executive of

the organization. There are 330

residents divided into

households of 14 residents each.

“When somebody is diagnosed,

their door is closed,” Mr.

Banoff said. Signs are posted

and safety gear is placed

outside the door so that staff

know to suit up before entering.

Still, the coronavirus has

cropped up in eight of the 23

households, 15 residents have

died, and four staff members

have been hospitalized, he said.

Administrators of nursing homes

large and small, as well as the

architects who renovate and

design their facilities, expect

to zero in on disease control in

the future as a result of the

pandemic. Air circulation and

filtration will be scrutinized

when heating, ventilation and

air conditioning systems are

planned, they said.

“I’ll be paying more attention

to the HVAC piece of it,” said

John Shoesmith, a Seattle a

architect who specializes in

senior living design.

The Facility

Guidelines Institute,

which writes planning and design

standards that are adopted in

most states and by federal

agencies, set up a task force

this month to make

recommendations for how health

care facilities can cope during

emergencies. Douglas S.

Erickson, the institute’s chief

executive, said the task force

would produce a white paper for

public review by the end of the

summer and publish new standards

in January 2022.

But

some providers are not waiting.

Evermore Senior Living is

wrapping up construction on the

first of 12 small houses for

assisted living and memory care

in Woodbridge, VA. Dave Risi,

the owner operator, said the

first building, which will

contain three households of

eight residents each, will open

in July. Because of the

coronavirus, he is now ramping

up air filtration.

Mr.

Risi already had high-efficiency

particulate air filters,

commonly called HEPA filters,

which can trap bacteria and

other particles. Because of the

coronavirus, he is now adding

ultraviolet light filters that

can kill airborne viruses.

Nursing home providers and their

architects are also talking

about easy-to-clean, nonporous

surfaces; antimicrobial

materials, like copper, for

“high touch” features such as

hand railings; and voice- or

sensor-activated controls for

doors, lighting, curtains,

faucets and toilets.

Even as they battle the

coronavirus, some nursing home

administrators are reassessing

renovation plans that were in

the works when the virus hit.

Andrus on Hudson, a nonprofit

senior care community in

Hastings-on-Hudson, N.Y., had

hired Amenta

Emma Architects to

help with a renovation. Now

James Rosenman, the chief

executive, is talking to the

designers about the possibility

of installing modular walls so

that resident rooms can quickly

be reconfigured in a crisis.

“It’s always been, ‘Do we need

to move the person?’’ Mr.

Rosenman said, referring to how

ill residents have been moved to

isolation areas during the

pandemic. “Maybe we can change

the rooms instead.”

https://www.nytimes.com/2020/05/12/business/nursing-homes-coronavirus.html

UV

Light for Jails and Nursing

Homes

The

Grant County Wisconsin Sheriff’s

Department recently purchased an

ultraviolet light emitter that

staff members use to sterilize

the county jail’s booking area

and holding cells.

The

device recently was lent to the

county’s nursing home, Orchard

Manor, which has experienced at

least 27 COVID-19 infections

among staff and residents.

The

UV light disinfects and cleans

almost every bug and virus out

there,” said Matt Thill, the

facility’s maintenance manager

“We’ve gone down through one of

the wings and disinfected every

room and bathroom, day room,

storage and utility rooms.”

The

device, manufactured by Grand

Rapids, Mich., company Skytron,

emits ultraviolet radiation that

damages the DNA or RNA in

pathogens present on nearby

surfaces, thereby reducing the

chances of infection.

To

prevent injury to users, rooms

must be unoccupied when the

device is turned on.

Onboard sensors on the UV

emitter scan rooms and determine

the intensity of light and

duration of operation needed to

sterilize the area.

The

device, which cost about

$41,000, is small enough to be

loaded onto emergency medical

services vehicles.

Currently at Orchard Manor, 17

residents with COVID-19 are

isolated in a negative-pressure

wing. The wing contains special

air filters that are designed to

prevent the spread of the novel

coronavirus, which causes the

disease.

Orchard Manor staff also

purchased a handheld UV light to

sterilize computer keyboards and

desks along with an ozone

generator that can disinfect

rooms

Washington State Dental Office

will Open with New Air Filters.

For

weeks, the Cannon Hill Dental

office has had a quiet, empty

waiting room. The only people

who came in were people with

dental emergencies.

But

starting May 18, all Washington

dental offices can re-open. Dr.

Amir Ganji, who runs Cannon Hill

Dental, says opening will be a

relief after dealing with the

frustration of being closed.

While

some dental work is not

considered essential, Dr. Ganji

says the lack of consistent

check-ups has caused problems

for some of his patients. He

stressed that the closure has

brought to light how essential

dental care can be.

That's why Dr Ganji is relieved

to open on May 19, the day after

Governor Inslee is allowing all

dental offices to re-open. But

opening a dental office could be

more complicated than opening

other businesses.

"We

are in a field where we generate

aerosol from the mouth, and it

goes into the environment," Dr.

Ganji said. That's exactly how

the coronavirus spreads.

In

order to keep his patients and

his team safe, Dr. Gangi bought

air filters, is doing fewer

procedures that create aerosol,

and has changed his scheduling

procedure. His office will be

seeing less patients than

normal.

Northwestern

Professor looking at Chemically

Treated Masks to Destroy Viruses

Jiaxing Huang, a professor of

materials science and

engineering at Northwestern

University, has

received a $200,000 grant

from NSF to

develop a chemical add-on for

traditional masks that can

destroy COVID-19.

Huang is looking at an

inexpensive way to incorporate

chemicals traditionally found in

sanitation products, which are

known to deactivate a broad

range of viruses. He’s looking

into sprays, as well as

chemically treated fabrics,

patches, and inserts for

disposable or DIY masks—all of

which would ramp up the

effectiveness of existing masks.

“What we need to worry about is

how to fix these agents so they

don’t [release] easily when

people inhale and get into their

lungs,” he says. “But then we

need to have them go away during

exhalation. That’s the science

challenge.”

Ben Gurion University

Researching the Potential for

Electrically Charged Graphene

Chris Arnusch, a water research

professor at Ben Gurion

University (BGU), in Israel,

spent five years developing porous

graphene membranes with

antimicrobial and antiviral

properties for use in water

purification. Now, he’s trying

to validate the technology for

air, with an eye toward adapting

it for masks or air filters.

Pure graphene is an atom-thick

layer of graphite, a component

used in pencil lead, that’s

incredibly strong and conducts

electricity. Arnusch creates a

foam-like form of graphene for

his filters by training a laser

on plastic surfaces. Armed with

seed funding from BGU and the

Israeli government, he’s now

teaming up with a startup to

commercialize this and other

products.

In the case of my water filters,

the pores are larger than the

bacteria and viruses,” says

Arnusch. “But if you electrify

the surface in water, it kills

the bacteria and viruses as they

pass through. I’m trying to see

if it works in the air. Once

proven, we just need to adapt it

to a mask or air filter.”

Graphene also being pursued by

Hong Kong Polytechnic

Laser-induced graphene also

interested Hong Kong Polytechnic

University researchers, who are applying

the material to

disposable surgical masks to

make them self-sterilizing and

ultra water-repellent, so

virus-laden droplets roll off.

In an April paper, they noted

that sunlight could

theoretically sterilize a

graphene-coated mask by heating

it to 176°F.

Carbon Nanotubes are Another

Option

University of Cincinnati

researchers are integrating a

carbon nanotube heater into a

fabric that’s made of carbon

nanotubes and polymer fibers.

The nanotubes’ small diameters

and collective high surface area

could effectively separate

microbes, while heating the

carbon could kill them. Having

successfully applied this carbon

nanotube heater technique to the

water purification industry, the

team is trying to use it to

filter air, with support from

the National Institute for

Occupational Safety and Health,

a division of the Centers for

Disease Control and Prevention.

Masks with Copper Technology

Offered by Multiple Companies

Masks which use copper

technology vary widely in terms

of degrees of effectiveness,

price, and longevity, with some

intended for healthcare use and

others purely as an upgrade from

fabric masks. Costs for single

masks generally run from $10 to

$70, with antimicrobial

properties lasting from 30

washes to the life of the

product. Some companies have

tested their products against

other viruses, though none have

against COVID-19, which requires highly

specialized facilities that

aren’t readily available. “Virus

size, infectivity level, and

chemical properties vary and

influence how well masks work,”

adds Fichtenbaum.

Some high-tech masks come at a

high price, in the $50 to $70

range.

Israeli fiber technology

company Argaman has

one featuring four

copper-infused layers and copper

oxide filters from Czech firm Respilon, which

also sells its own masks.

Israeli startup Sonovia uses

zinc oxide coating and

five-micron filtration that is

supposed to last a year.

Companies that specialize in

copper-infused antimicrobial

apparel and mask specialty

outlets offered more affordable

versions. Copper

Compression and

the U.K.-based Copper

Clothing offer

four-layer masks blocking 99% of

particulates, while Copper

Mask uses

six-ply copper and HEPA filters

blocking 92%. Another company, Kuhn

Copper Solutions—founded

by microbiologist Phyllis Kuhn,

an early

advocate of copper use in

hospitals—specializes

in copper mesh masks and inserts

that can be combined with

traditional or cloth versions.

You can also find copper-infused

cotton masks at some furniture

and apparel outlets—like The

Futon Shop, CustomInk,

and Atoms shoes—that

hopped on the copper bandwagon

by leveraging existing

production pipelines.