Coronavirus Technology Solutions

May 6, 2020

New Coronavirus Strain Creates Challenges

Do we Need Masks with Valves for Certain People

and Certain Situations?

Filtration Webinar on May 5 also Provides

Coronavirus Insights

Signature Health Care is Using UV to Sterilize

Masks

Turkey has the best EU ICU Capacity at 40 beds

per 100,000 People

Pressure Sensors are Important to Keeping Rooms

Isolated

CWS Provides Guidance on Coronavirus for

Cleanroom Operators

Should Cleanroom Operators Treat Coronavirus as

Part of a Box Within a Box?

Cigarette Smoke is Similar in Particle Size to

Some of the Coronavirus Aerosols

Modify Restaurants and Subways as if you are

Protecting Against Cigarette Smoke

China is Expanding Meltblown Capacity Rapidly

but with Difficulty Controlling Quality

Cloth Masks do not Protect Wearer or Others

Restaurant Air Flow has to be Redesigned

to Allow Them to Open Safely

______________________________________________________________________________

New Coronavirus Strain Creates Challenges

A new, recently discovered strain of the

coronavirus has a leading researcher concerned

that it will present a difficult challenge to

the vaccines currently under development.

Dr David Monterfiori of Duke University was

involved in a study with a team out of the Los

Alamos National Laboratory that has identified

the new strain. They said the new strain may be

more contagious but is no more deadly the other

strains of illness.

A viable vaccine is one of the key elements

toward responding to the disease in the future

and several tests are currently in process. Many

researchers believe another severe COVID-19

outbreak could take place this fall including

UCSF epidemiologist Dr. Gene Rutherford. “We’re

gearing up now, our big concern is about a

second wave in the fall,” he told KPIX 5.

Monterfiori’s research may indicate that the

illness will be driven by the new strain and

that it is already here. It became very evident

that this new mutant form of the virus was

spreading rapidly,” he said. The mutation

involves the spikes that stick out from the

surface of the virus. “That’s how it attaches to

cells and gets into cells,” Monterfiori said.

If you are already infected with COVID-19,

that’s the spot where the antibodies would block

the virus from infecting you again. But your

body’s reaction may not be strong enough when it

comes to the new strain. Monterfiori worries

about how it will impact how a vaccine under

current development may combat the illness.

“That’s the protein that’s in all the vaccines

right now,” he said. “And so we’re concerned

that the mutation in this new form of the virus

will be a problem for the current vaccines.”

Do we Need Masks with Valves for Certain People

and Certain Situations?

Two Chinese boys dropped dead within a week of

one another while wearing face masks during gym

class. The students, who were both 14, were each

running laps for a physical examination test

when they suddenly collapsed on the track. One

student at Changsha’s Xiangjun Future

Experimental School in Hunan province had been

wearing an N95 respirator and running a

1,000-meter exam when the fatal incident

occurred. It’s unclear whether an autopsy had

been ordered.

Though it’s not known whether the masks played a

role in either death, several schools in Tianjin

and Shanghai have canceled physical education

exams, according to the report.

These incidents raise the question as to whether

N95 masks with valves should be substituted for

those without valves under certain conditions.

One would certainly be heavy exertion.

Another would be individuals who have underlying

conditions e.g. asthma where breathing is more

difficult that it would be for the average

person.

Filtration Webinar

on May 5 also Provides Coronavirus Insights

A webinar held by the Waterloo Filtration

Institute on Tuesday

provided a good summary of the filtration

industry and brief insights on the coronavirus

challenge by Paul Marold, president of Lydall,

and Val Hollingsworth, CEO of Hollingsworth &

Vose. Bob Mcilvaine was also a speaker.

Details are found at

Signature Health Care is Using UV to Sterilize

Masks

Signature Healthcare Brockton

Hospital is using ultraviolet light to sterilize

and reuse N95 masks to care for patients,

including those who have tested positive for the

coronavirus.

Under normal circumstances,

hospital staff wouldn’t reuse personal

protective equipment, said Stephen Borges, vice

president of operations for Brockton Hospital.

But given the increased need for gear to treat

coronavirus patients and a nationwide shortage

of it, the hospital wanted to find a way to

reprocess masks and make them available to

staff.

“The fact that we’ve

processed them and packaged them up makes it a

little easier to reuse them,” he said. “It gives

the staff some sense ... It’s not optimal, but

it’s much better to be able to reuse the masks

and that the equipment to do this is available,”

said Borges.

But given the increased need

for gear to treat coronavirus patients and a

nationwide shortage of it, the hospital wanted

to find a way to reprocess masks and make them

available to staff.

Turkey has the best EU ICU Capacity at 40 beds

per 100,000 People

Turkish health care, armed with a pandemic

preparedness plan issued long before the

outbreak emerged in the region, has been hailed

by experts for offering a good, timely response

to the pandemic. Turkey also boasts an intensive

care unit bed capacity that is the largest in

Europe, with 40 beds per 100,000 people.

Recently, the country started unveiling new

hospitals whose construction was accelerated to

help combat the outbreak. Last month, the

Başakşehir City Hospital in Istanbul was

partially opened to serve as a pandemic hospital

while construction of two new hospitals in the

city, each with a 2,000-bed capacity, was

launched last month. The construction is

expected to wrap up in 45 days. Also in March,

authorities unveiled a new hospital in the

city’s Okmeydanı district with more than 600

beds and 99 high-tech intensive care units.

Sancaktepe Şehit professor İlhan Varank of the

Istanbul Training and Research Hospital is among

those facilities turning to negative pressure

rooms to further stem the tide of the virus. The

pandemic hospital admitting the greatest number

of patients in Istanbul, the facility is staffed

with 1,900 personnel working day and night and

has converted a significant number of areas,

including 16 surgery rooms and 75 intensive care

beds, into negative pressure rooms. The rooms

offer a relief for the staff of the hospital,

which has admitted nearly 60,000 patients since

March, including about 11,000 suspected

coronavirus cases. Along with handling a barrage

of COVID-19 patients, staff have continued to

carry out surgeries, including on those

suspected of having the virus. So far, about 300

patients, suffering from other diseases have

been operated on.

Pressure Sensors are Important to Keeping Rooms

Isolated

Many facilities are geared to meet minimal CDC

and Joint Commission guidelines around isolation

rooms. However, there is a huge opportunity for

hospitals to update the technology that ensures

proper isolation room pressurization. One of the

most resourceful methods to verify pressure

measurements is through real-time pressure

monitoring and alert notifications.

The SensoScientific Differential Pressure

Monitoring System is designed to meet CDC, USP,

ISO/IEC, and Joint Commission compliance

standards. The latest OTA Series Differential

Pressure Sensors enter a low-power mode between

readings, ensuring accuracy, reliability, and

product longevity.

These devices piggyback off

existing Wi-Fi to upload readings to

SensoScientific Cloud, accessible from any

internet-ready device. Through the cloud, the

user can access unlimited data records, generate

reports, view calibration certificates, and

receive 24/7 alert notifications the moment

isolation room pressure exceeds the recommended

threshold.

Loggers can be installed according to IQ/OQ/PQ

standards and are a low maintenance solution to

pressure monitoring and regulatory compliance.

✓ Positive

and negative airflow

✓ Range:

+/- 0.5 inH2O

✓ Accuracy:

+/- 0.01 inH2O

✓ Uni-

and bi-directional pressure measurement

✓ Real-time

alert notifications

✓ IQ/OQ/PQ

compliant

✓ ISO/IEC

17025

Differential Pressure monitoring systems help

prevent the spread of infectious diseases and

maintain sterile work environments by actively

measuring pressurized airflow between a positive

or negative buffer room and the ante-room.

Wide-range wireless differential pressure

sensors monitor bi-directional and

unidirectional pressure and use Wi-Fi to send

information to the cloud. It

notifies

via email, SMS text, voicemail, fax, or

pager when negative or positive pressure rooms

are not maintaining proper readings.

CWS Provides Guidance on Coronavirus for

Cleanroom Operators

The CWS Cleanroom blog observes that the

coronavirus SARS-CoV-2 poses great challenges

for cleanroom operators. Particularly in

cleanrooms, it is important that viruses and

bacteria cannot transmit via employees or their

clothing. But can this really be achieved? Where

are the pitfalls and how can they be countered?

Dr. Rüdiger Laub, Head of the Cleanroom Academy

was interviewed

to provide the following information.

Dr. Laub, is it possible to prevent SARS-CoV-2

from entering the cleanroom?

No - the penetration of viruses into cleanrooms

cannot be completely prevented.

However, much can be done to prevent the virus

from finding its way into the cleanroom - for

example, by wearing appropriate cleanroom

clothing and accessories such as goggles, gloves

and other protective materials. And of course,

making cleanroom users aware by training and

instruction. The risk potential is highly

dependent on their behavior. However, even with

the utmost caution, there will never be 100%

safety. Because the weak point is the cleanroom

user. Due to the long incubation period,

employees could potentially carry the virus, and

thus transmit it while not feeling ill, or

perhaps haven't felt any symptoms yet.

Provided that sufficient testing capacity is

available, cleanroom personnel could be tested

preventively in so-called "critical

infrastructures" - for example, in cleanrooms of

hospital pharmacies - at very short intervals or

if suspicion exists. Basic principle: Early

detection - early removal from processes -

reducing risk.

Let's move on to the topic of prevention: What

additional protection options do you currently

recommend for cleanroom personnel to prevent the

coronavirus from being transmitted into the

cleanroom?

Basically, the airlock processes, cleanroom

clothing, behavior, as well as robust cleaning

and disinfection measures form very effective

barriers against the penetration of viruses;

however, SARS-CoV-2 is particularly treacherous

and demands further measures. In this

exceptional situation, more protection is

advisable. I therefore recommend the following

supplementary measures to keep the risks to a

minimum: As a matter of principle, only one

person should currently be in the airlocks

leading directly to the production areas.

Another starting point is protective clothing -

for example face protection. This should now

also apply in the cleanroom classes where this

is currently not provided as standard - i.e.

also in the GMP cleanliness classes D and C /

ISO cleanliness classes ISO 9 to ISO 6. Since

the virus can be spread further via the hands,

gloves are currently also a must in all

cleanrooms - even if it is not provided for the

normal protocols for that cleanroom class.

Additional protection is provided by cleanroom

wipes, which can be used to clean surfaces and

other items as required.

The remainder of this interview can be found at

Should Cleanroom Operators Treat Coronavirus as

Part of a Box Within a Box?

The CWS interview with Dr Laub talks about

certain measures for coronavirus mitigation to

be taken prior to entering the cleanroom such as

masks and a procedure to pass through the

initial airlock. Should operators be thinking of

the cleanroom as a box within a box? The big box

is the Class 500,000 area surrounding the

cleanroom. What if this is reduced to Class

100,000?

What if every employee in street shoes

has to step on a UV/Ozone foot sanitizer? What

if the mask protocol in the larger box and in

travel to and from work is coordinated with a

mask exchange program at the plant entrance?

As the McIlvaine Alert shows, an N95

quality mask is needed due to the fact that much

of the virus transmission is through small

aerosols. So the Cleanroom operator can provide

masks for travel to and from the cleanroom.

Cigarette Smoke is Similar in Particle Size to

Some of the Coronavirus Aerosols

In an AFS publication, Wilson Poon of W.L. Gore

provided analysis of cigarette smoke particle

size.

Cigarette smoke is an important aerosol in the

air filtration industry and research. It is an

unwanted aerosol and therefore there are many

applications for air filtration (ex. cigarette

filters, residential and commercial ventilation

filters, home air cleaners).

Cigarette smoke is especially important to air

filter performance for several reasons. First,

the size of cigarette smoke particles are near

the most penetrating size of air filters

(100-300 nm). As a result, they are relatively

difficult to capture. Secondly, the efficiency

of electret filter is severely degraded by the

semi-volatile cigarette particles. It is

believed that they form a film on the fiber

surface and effectively shield or remove the

charges. If this occurs, the electrostatic

efficiency of the filter suffers. The remaining

mechanical efficiency is usually poor because

electret is a depth filter and the fiber size is

relatively large. Furthermore, a cigarette can

produce a large amount of aerosol quickly.

Imagine a room with several cigarette smokers!

Whereas large particle (>5 micrometer diameter)

tends to settle down by gravity quickly,

cigarette smokes are relatively stable and their

lifetimes can be on the order of days or weeks.

Therefore, cigarette smoke can be viewed as a

stringent test for air filters.

The paper linked below provides

the results of particle size measurements

done by previous researchers. The count median

particle size is between 0.1 to 0.3 μm, near the

most penetration particle size of high

efficiency particulate arrestor (HEPA) filters.

For depth filtration media like microfiberglass,

the loading of smoke particles would not be

detrimental because the oil droplets can wet the

fibers and spread out. For microporous membrane,

the loading of smoke particles can have a

detrimental effect on the pressure drop. Due to

surface filtration, the oil droplets are

collected near the surface. As the oil

accumulates on the surface, it chokes off the

airflow. It is therefore not recommended to use

microporous membrane in environments with

cigarette smokers.

https://www.afssociety.org/cigarette-smoke-size-distribution-and-effects-on-filters/

Modify Restaurants and Subways as if you are

Protecting Against Cigarette Smoke

McIlvaine has questioned the CDC guidance to

meat processors to install partitions around

workers. Further questions are raised about

social distancing due to the small size of

coronavirus aerosols. The article above analyzes

the size of cigarette smoke. Numerous articles

in this Alert

show that a significant quantity of virus

is transmitted in aerosols or on particles of

similar size to cigarette smoke.

McIlvaine summarized this in

Laminar Flow Not Partitions and Masks Not 6 ft

Distance are the New Recommendations

It is well understood that cigarette smoke will

move around partitions and drift much farther

than six feet.

Unidirectional

flow, HEPA filters and N95 masks are the answers

for many situations.

One would be subway stations.

Another would be restaurants where the guidance

has been to reduce occupancy to 25 percent.

As can be seen from the smoke filled bar

below, distancing is not an effective solution.

In a study of coronavirus transmission in a

restaurant in Southern China the biggest factor

was the air flow pattern. Those far away from

the transmitter but in the air flow pattern of

the air conditioner became infected. Those close

but not in the air stream did not. So the answer

is HEPA filtration and unidirectional air flow

away from individuals such as vertical downward

flow. Restaurants could invest in a few fan

filter units at $2k each and seat more people at

less risk.

China is Expanding Meltblown Capacity Rapidly

but with Difficulty Controlling Quality

In China, the largest exporter of medical masks

in the world, about 4,000 new companies have

registered to manufacture or trade melt-blown

fabric since the beginning of the year,

according to Tian Yan Cha, an online service

tracking companies' credits and registries. Last

year, only about 300 new companies registered

melt-blown businesses.

Yangzhong, a city of about 340,000 residents in

Jiangsu province, became a marketplace for

melt-blown fabric seemingly overnight.

Machines that used to produce other types of

nonwoven fabric were converted to make the

melt-blown fabric. Most of these machines came

from nearby cities such as Zhangjiagang,

about 100 miles away from Yangzhong

Zhe Huang, who manufactured nonmedical masks in

Zhangjiagang, said it’s not easy to make

medical-grade masks. They require strict

production conditions such as a dust-free work

site and filters that meet medical standards.

To make the filter fabric, thousands of solid

polypropylene granules are melted and extruded

from nozzles into high-velocity hot air streams,

forming fine filaments, “the size of your hair,”

said Gajanan Bhat, who heads the Department of

Textiles, Merchandising and Interiors at the

University of Georgia. Those ultra-fine fibers

are bonded and collected on a moving screen,

becoming a sheet of webs. “It’s like a spider

web; multiple layers of spider webs,” said Bhat,

who has published extensive research on

melt-blown fabric and the spunbond fabric that

sandwiches it in masks.

By April 9, local media had caught on to what

was happening in Yangzhong and took a critical

stance: “The myth about being a billionaire from

the melt-blown fabric encourages farmers to stop

their farming, workers to quit their stable

jobs and companies to throw away their

reputation to join this gold rush,” the

Yangzhong Daily Newspaper wrote on its front

page.

Public signs of trouble for the startups

appeared two days later, on April 11, in a news

release from Yangzhong’s emergency management

bureau. It accused a melt-blown company of

violating the Production Safety Law of the

People's Republic of China. The agency said the

company didn’t post obvious safety warnings on

its air compressor and hadn’t put its employees

through safety training.

The next day, the emergency management agency

found a hotel in Jingkai District of Yangzhong

had violated fire ordinances by using some of

its rooms for manufacturing the melt-blown

fabric. The hotel, it reported, was temporarily

sealed up and under investigation.

Almost as quickly as the industry appeared in

Yangzhong, it disappeared. Mounting concerns

about the quality of the product brought its

melt-blown fabric manufacturing to a grinding

halt.

A 95% filtration rate is required for

medical-grade surgical masks, according to the

American Society of Testing and Materials. High

protection masks such as N95s should have a rate

of 98% or higher.

Yangzhong’s Administration for Market Regulation

randomly tested fabric from eight manufacturers

of melt-blown fabric in early April. When the

agency's report came out, five of the samples

met neither standard, and only two could be used

for high-protection masks. Three were not even

close, filtering out 45% or less.

On April 14, the city noted in a news release

that it had been pushing to overhaul illegal

melt-blown production since late March and

issued warnings to 225 enterprises making or

selling “three-no” textiles – products without

production date, name of manufacture and

sanitary certificate.

The next day, the city went further, shuttering

867 melt-blown businesses. Wei was surprised to

see his hometown pop up as a hot search on Weibo

for a post reporting that “#All Yangzhong

companies that produce the melt-blown fabric

shut down for rectification.”

Wiping out the melt-blown industry in Yangzhong

probably won’t be the end of it, according to

dozens of experts in the industry contacted by

USA TODAY, including manufacturers, investors

and traders. The demand is too great.

Even as the city cracked down on all the fabric

production, melt-blown makers loaded their

machines into their car trunks and transferred

them to nearby cities.

In February, the average retail price for the

fabric in China increased tenfold, from 40,000

yuan per ton to 400,000 yuan per ton, according

to China Merchants Securities. Before the

COVID-19 pandemic, the market price for such

fabric in China was 20,000 yuan – about $2,800 –

per ton, according to China's State

Administration for Market Regulation.

Masks that leave China through official channels

go through extensive certification intended to

prevent exports of substandard material.

Entering the USA adds another layer of scrutiny.

There are other routes.

Relatively small orders from individuals – or

even larger organizations – can be sent through

the mail.

Last month 25,000 counterfeit masks from China

were found at a DHL hub in Kentucky.

Cloth Masks do not Protect Wearer or Others

In an interview with Infection

Control Today®, Lisa Brousseau,

ScD, expert on infectious diseases said that the

CDC’s suggestion that cloth masks offer any kind

of protection flies in the face of the data. “It

was clear that even surgical masks weren’t

working in healthcare settings or controlling

COVID-19,” Brousseau said.

Brousseau also said: “Surgical masks, I decided,

based on the literature, might have a role as

source control for people who have symptoms. Say

if they’re staying home and they have some

symptoms. They shouldn’t be something you’d wear

if you have symptoms going out into the public

because you shouldn’t be going out into the

public service. But it’s a good option for

patients to wear in healthcare settings where

they—especially for those who are experiencing

symptoms—to what I would call diminish the viral

load.”

She added that “at the end of the day, the only

thing that provides personal protection for the

person wearing the mask is a respirator.”

https://www.infectioncontroltoday.com/mask-respirators/cloth-masks-are-useless-against-covid-19

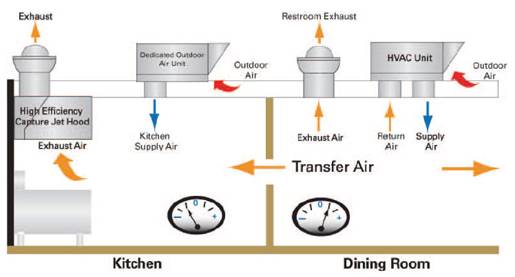

Restaurant Air Flow has to be Redesigned

to Allow Them to Open Safely

Previous McIlvaine articles discuss using

ceiling fan filter units in the restaurant

dining area and then downward laminar flow of

HEPA filtered air. The extent to which

this air could move at floor level and

then become part of the kitchen exhaust would be

beneficial in terms of

minimizing viral contact.

Here is the system which has been offered

by Trane and needs to be revised.