Coronavirus Technology Solutions

May 1, 2020

HEPA Filtration Systems for Locker Rooms

Amaircare has Air Purifiers Ranging From 20 to

10,000 CFM

CDC Guidance for Meat Packers Does Not Specify

N95 Masks

Air Purifiers with H2O2 Used by Gliers Goetta

Extreme Microbial Technologies has Three Stage

Air Purifier for Food Plants

A New Plane Seat Design Could be the Future of

Travel Post-Coronavirus

RAYCOP Products' UV Sanitizing Light Kills

Viruses and Bacteria

Virus Particles Less Than 4 Microns Detected in

Air in Isolation Rooms

Sartorius Air Samplers Have Been Used for

Extensive Coronavirus Monitoring

Large Number of COVID-19 Cases at Nuclear Plant

Construction Site

EverBlock Systems Providing

Temporary Isolation Rooms

Buses In China Transmit Virus Through Air

Conditioning System

______________________________________________________________________________

HEPA Filtration Systems for

Locker Rooms

There are two main reasons to

use an air purifier in a locker room setting.

The first of these is the fact that locker rooms

are home to unpleasant odors that can make

people less interested in coming to a gym. The

second is the fact that bacteria, viruses and

fungi are quite common in these environments.

Removing these contaminants from the air can

help your gym patrons stay healthy and ensure

they can change and shower in a clean setting.

Related

to this last point is the fact that the right

air purifier can help to keep chemicals from

building up in the air. For purposes of

cleanliness, many gyms use strong chemical

cleaners in their locker rooms. While this is

necessary to get rid of potentially harmful

bacteria, the fumes from these cleaners can

build up and have a negative impact on people

who suffer from asthma or other respiratory

illnesses.

Amaircare has Air Purifiers Ranging From 20 to

10,000 CFM

Amaircare has a 20 year portfolio of custom air

treatment solutions and projects diverse in

scope, competency and scale. Amaircare combines

proprietary technologies with flexible

components to create the highest of quality

and performance solutions with air flow

options between 20 CFM and 10,000 CFM.

Over the years, Amaircare products have provided

tailored solutions for a wide range of

applications, including:

-

protection of employees in

industrial plants and workspace

-

controlling ambient biologicals

in food processing

-

reduction of emissions in

receiving areas

-

process control of emissions

reducing or eliminating the need

to exhaust

-

creating a safe environment for

medical patients with reduced

immune systems after cancer

treatment

-

protection of medical

practitioners dealing with

airborne pathogens, such as: the

COVID -19 outbreak

CDC Guidance for Meat Packers Does Not Specify

N95 Masks

The following CDC guidance for meat packers may

be poor based on the new evidence that aerosols

will float around plexiglass barriers and that

social distancing means little compared to the

travel pattern of the aerosol. Plexiglass

barriers may even create turbulence if air is

moving horizontally instead of downward and the

HVAC system does not have HEPA filters. Most

cloth masks will not protect against aerosols.

To ensure continuity of operations of essential

functions, CDC advises that critical

infrastructure workers may be permitted to

continue work following potential exposure to

COVID-19, provided they remain asymptomatic and

additional precautions are implemented to

protect them and the community,” the CDC’s Critical

Infrastructure Guidance states.

The agency also notes that screening workers for

COVID-19 symptoms is “an optional strategy”.

Meat processing workers are not exposed to

COVID-19 through product handling; they can be

exposed via close contact with other employees

in a facility. The CDC and OSHA have released

interim guidance for meat

and poultry processing workers and employers that

details how communal work environments should be

laid out and how employers should be promoting

social distancing. Engineering controls include

the following:

-

Reconfiguration of workstations

to allow employees to be six

feet apart, if possible

-

Establishing physical barriers

(i.e., plexiglass or strip

curtains) to separate workers

-

Working with an HVAC engineer to

establish proper ventilation

that limits potential exposure

to coronavirus; removal of any

pedestal or personal fans

-

Setting up handwashing stations

or hand sanitizer (60% alcohol)

stations

-

Reconfiguring break rooms and

other communal areas to promote

social distancing

The CDC also recommends that workers wear cloth

face coverings that fit over the mouth and nose.

For workers who have experienced COVID-19

symptoms and have self-isolated at home, the CDC

advises they do not return to work until they

meet specific

criteria.

Air Purifiers with H2O2 Used

by Gliers Goetta

Glier's

Goetta is not a large meat manufacturer. Only 18

people work inside the factory. The company

still faces the challenge of getting the job

done in close quarters.

"It's a tough one just

because of the way the process runs, the

disassembly lines, if you will. The meat

cutting, the boning, things like that. People

are fairly close to each other. And yes, we can

put up shields, but that's still not going to do

the job. It takes technology like this to really

get us over the hump," said Dan Glier, CEO of

Glier's Goetta.

A white box-like machine is

the technology Glier said is keeping his

employees working.

"When we're working in, you

can't smell anything. You can smell...when you

first walk in the room, but it just cleans

everything, including people," said Glier.

It's an air and space

purification system made by Dayton-based Extreme

Microbial Technologies. The system uses hydrogen

peroxide to clean the air. To keep production

up, Glier's has three air purifiers inside and a

fourth on the way.

"It's good for our people

too. We don't have colds like we used to because

people are living in this, you know, probably 8

to 10 hours a day," said Glier.

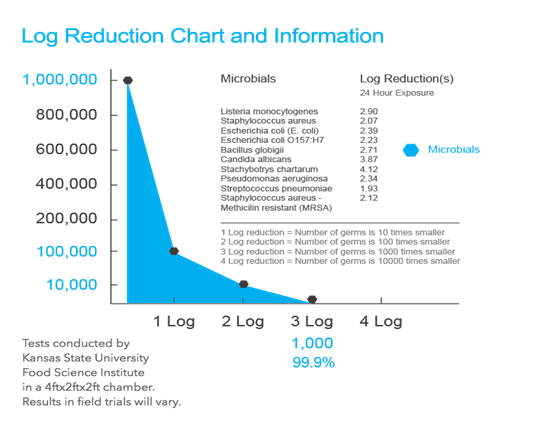

Extreme Microbial

Technologies has Three Stage Air Purifier for

Food Plants

This surface & air purification equipment has a

design for a variety of industrial and

commercial applications. Some of these include

warehouses, production facilities, large office

spaces, hospitality, athletic facilities, food

production facilities and more. It provides a

safe and effective three-stage solution for the

reduction of bacteria, viruses, molds, fungi,

mildew, and VOC’s (which cause odors).

Additionally, each PRO™ features a pre-filter, a

HEPA filter and two specially enhanced

Photocatalytic Oxidation cells to flood the

space with powerful and effective air and

surface scrubbers.

A New Plane Seat Design Could be the Future of

Travel Post-Coronavirus

The new designs would see hygiene screens fitted

in each seat, as well as new middle seats which

would face backwards while flying.

4

The revolutionary sitting arrangement was

revealed by Aviointeriors, the same company who

created stand-up seats for aircraft cabins.

In economy class, each seat would have a plastic

screen around the head and side, preventing

contact with the passenger next to them.

The screen, called Glassafe, is transparent to

allow communication but will prevent the spread

of any viruses between travelers.

It can also be fitted onto existing economy

seats and leaves the lower part of the seat free

for passengers to continue using the in-flight

entertainment or to eat their meals.

The design firm explained: "Glassafe [creates]

an isolated volume around the passenger in order

to avoid or minimize contacts and interactions

via air between passenger and passenger, so as

to reduce the probability of contamination by

viruses or other."

Other designs previously suggested to make plane

travel easier include "privacy panels" which can

be folded out of the side of the seat.

The design, called Interspace Comfort System,

looks like your regular plane seat but if you

lift up the seat back, you'll find two hidden

panels behind it that fold out, effectively

creating a privacy divider on either side of

you.

The ease of access means that passengers can get

in and out of their seats easily and create

private spaces for families and friends who are

sitting together.

It will be important for designers to integrate

the divider design into the air flow system.

Each seat has an adjustable nozzle which

should direct air downward and not to other

seats

RAYCOP Products' UV Sanitizing Light Kills

Viruses and Bacteria

According to just-released new research from the

Kitasato Research Center for Environmental

Science,

using an Ultraviolet C (UVC) sanitizing light

can help kill viruses such as influenza.

Commissioned by RAYCOP, a maker of UV allergen

vacuums, the

research

noted that UVC wavelength light, as opposed to

UVA or UVB, is the most effective against

viruses.

Immunologist Dr. Michael Lee founded RAYCOP to

help people make their homes healthier and to

mitigate allergies. He sought products he could

recommend to his patients with the goal of

preventing the onset of allergies and avoiding

the need to take medications. To that end, Dr.

Lee invented RayClean Technology©, which

captures 99.9% of potentially harmful

microorganisms that you can’t see such as

viruses, bacteria and dust mites.

“My goal was to help my patients by creating a

safe and effective UV light sanitizing vacuum

for the home,” says Dr. Lee. “Keeping homes

healthier is of the utmost importance -

especially now as people are sheltering in place

- and our RayClean Technology has been in use

since 2005. This technology kills dust mites and

also greatly reduces allergens in the home,

lessening symptoms year-round for allergy

sufferers.”

“Our mission is to clean the unseen,” explains

Hirobumi Suzuki, CEO, RAYCOP North America.

“During this uncertain time, we especially want

to make your home a safer and cleaner place to

live.”

RAYCOP’s hand-held UV allergen vacuum, the RN,

includes a four-stage filtration system. This

system incorporates a high-efficiency

particulate air filter, UVC ultraviolet light,

optimized suction and a dual-motor brush head.

The RN utilizes RayClean Technology to remove

99.9% of bacteria and viruses from fabrics

within a few seconds. According to a study by

the

National Center for Biotechnology Information,

UVC light also reduces the hatchability of dust

mite eggs. This in turn reduces future

allergy-causing dust mite populations.

Virus Particles Less Than 4 Microns Detected in

Air in Isolation Rooms

Understanding the particle size distribution in

the air and patterns of environmental

contamination of SARS-CoV-2 is essential for

infection prevention policies. In an aim to

detect SARS-CoV-2 surface and air contamination

and study associated patient-level factors. 245

surface samples were collected from 30 airborne

infection isolation rooms of COVID-19 patients,

and air sampling was conducted in three rooms.

Air sampling detected SARS-CoV-2 PCR-positive

particles of sizes >4 μm and 1-4 μm in two

rooms, which warrants further study of the

airborne transmission potential of SARS-CoV-2.

56.7% of rooms had at least one environmental

surface contaminated. High touch surface

contamination was shown in ten (66.7%) out of 15

patients in the first week of illness, and three

(20%) beyond the first week of illness (p =

0.01).

https://www.medrxiv.org/content/10.1101/2020.03.29.20046557v2

Sartorius Air

Samplers Have Been Used for Extensive

Coronavirus Monitoring

We

reported on testing in Wuhan which found high

virus levels in changing areas and other

spaces. This was done with Sartorius equipment.

These analyses were made with Sartorius air

samplers. The MD8 air samplers, MD8 Airscan® and

the portable AirPort MD8, are designed to detect

smallest viruses and microorganism in the air by

using the unique Gelatine Membrane Filters (GMF)

and BACTairTM agar plates. MD8 Airscan®

and AirPort MD8 monitors ambient air in

cleanrooms, controlled, and public areas for

viable microorganisms.

The MD8 Airscan® and AirPort MD8 provides

non-stop, active air monitoring for at least 8

hours, using only a single gelatin membrane

filter. Rule out false negative results; the

proprietary, USP-approved filter retains even

the smallest airborne microorganisms and

monitors viability at the most accurate level.

Large Number of COVID-19 Cases at Nuclear Plant

Construction Site

More than 170 workers on a construction project

in a nuclear power facility in Georgia have

tested positive for the coronavirus, and

absenteeism has “increased dramatically,”

according to documents and a spokesman for

Georgia Power, the utility company that is a

part owner of the facility.

The facility, Plant Vogtle, is near Waynesboro,

Ga., about 150 miles east of Atlanta, and has

been in operation since 1987. It is in the

middle of a multibillion-dollar expansion that

has been plagued with setbacks, including

construction problems, cost overruns and the

2016 bankruptcy of Westinghouse, its lead

contractor.

As of March, the expansion employed more than

9,000 workers, making it the largest

construction project in the state, according to

North America’s Building Trades Unions, which

represents many of the Vogtle workers.

But after concerns about the spread of the virus

mounted in recent weeks, the plant’s owners

reduced the work force on the expansion project

by 20 percent.

Of the 171 workers found to have the coronavirus,

90 are “active confirmed positive cases” and 81

are workers who recovered and are “available to

return to work,” John Kraft, the spokesman for

Georgia Power, said in an email late Thursday.

Mr. Kraft said that 439 workers tested negative,

and that 48 were awaiting test results.

The owners learned of the first worker to test

positive on April 4, Mr. Kraft said. Around that

time, some workers told

a local TV station that they were

concerned that not enough was being done to

protect them from the virus on the work site.

The smaller work force, Mr. Kraft said, will

allow for increased social distancing. The site

has banned large group meetings, expanded an

on-site medical clinic, and added portable

bathrooms and hand-washing stations, among other

changes. And testing will continue.

EverBlock Systems Providing

Temporary Isolation Rooms

EverBlock Systems, LLC., the leading

manufacturer and provider of modular building

systems is working with the Governor’s response

team in New Orleans, LA to provide thousands of

modular wall panels and life-size building

blocks to be used in building a temporary pop-up

hospital facility in the Ernest M. Morial

Convention Center.

Sleeping pods, isolation units, nursing

stations, bed areas, testing sites and more will

be built throughout the convention center using

modular and durable building blocks, as well as

EverPanel modular sanitary divider walls to

mitigate the spread of the Coronavirus

(COVID-19).

EverBlock responded to the call to deploy

equipment and personnel within a few days,

enabling the EverBlock team to set up over 2,000

sleeping pods in record time using it’s unique

modular wall panels and building block systems.

Equipment continues to roll off of the

manufacturing line and onto trucks bound for New

Orleans.

Government is monitoring the pandemic and will

determine if additional hospital beds, dividers

and rooms will be necessary depending on how the

outbreak continues to spread in the New Orleans

metro.

EverBlock Systems. LLC, a New York based company

manufactures life-size modular building blocks

and modular sanitary divider walls to segregate

populations, such as for homeless shelters,

temporary hospital installations, disaster

relief facilities, and for disease spread

mitigation.

Buses In China Transmit Virus Through Air

Conditioning System

Practical

Preventive Medicine

published the

paper

in early March titled "An epidemiological

investigation of 2019 novel coronavirus diseases

through aerosol-borne transmission by public

transport," The authors, from institutions in

China, looked at the spread of the virus on a

bus linked to one infected passenger.

According to the abstract, This COVID-19

outbreak was transmitted by a public transport

resulting in 11 confirmed cases including one

asymptomatic case and two third-generation

cases. The farthest transmission distance of

COVID-19 in the airtight air-conditioning bus

reached 4.5 meters.

This contagious virus could float in the air for

30 minutes at least and cause infection.

The researchers concluded: The COVID-19 has

strong transmissibility and can be transmitted

by aerosol in a closed environment. To prevent

infection, personal protection should be done

well when taking public transports

and the ventilation and fresh air volume in

public transports should be guaranteed, and the

cleaning and disinfection in the carriage should

be done well.