Coronavirus Technology Solutions

April 21, 2020

Viroblock Effective Against Coronavirus

Sciessent Antimicrobial in Nextera Mask

Spectrashield Meets Efficiency Requirements

Berry Global has New Material for Surgical Masks

NC State Develops Two Polymer

Spunbond for Masks Which Can Be Sewn and is

Washable

Sandler Building a New Non

Wovens Line for Mask Media

Mitsui Chemicals has Expanded Melt Blown

Capacity

Three Layer Wipe is a Good Solution for

Coronavirus Mitigation

Large Non-Woven Demand to Mitigate Virus

______________________________________________________________________________

HeiQ Viroblock NPJ03, an antiviral and

antimicrobial textile treatment was tested

effective against coronavirus.

Since its inception 15 years ago, HeiQ has

forged a solid innovation track record helping

brands improve textile products. Catalyzed to

action by the global fight against Coronavirus,

HeiQ launched HeiQ Viroblock NPJ03, an antiviral

and antimicrobial textile treatment which is

proven effective against human coronavirus

(229E) in face mask testing, significantly

enhancing the antiviral log reduction from 2.90

of untreated face masks to 4.48, over 99.99%

reduction of virus infectivity. A log reduction

of two is equivalent to 100 times the

effectiveness.

“Virologist Dr. Thierry Pelet of HeiQ’s

Scientific Advisory Board brought us a profound

depth of knowledge and accelerated our efforts

to address the urgent problem of a global

pandemic,” says Carlo Centonze, HeiQ Group

CEO. “Our goal is to prevent textiles from

becoming a host surface for propagating harmful

viruses and bacteria and contribute to reduce

the risk and speed of contamination and

transmission.”

Chinese protective masks producer Suzhou Bolisi is

the lead adopter of HeiQ Viroblock NPJ03.

Treated masks will be available on the market as

early as this month. American legwear

manufacturer Kayser-Roth is planning to add the

technology to their new product, Ghluv hands

protector, while Lufeng from China is evaluating

the technology on other types of fabric used for

garments.

“I’m impressed by HeiQ’s ability to fast track

such a complex innovation and bring this

breakthrough to globally critical products in

short time,” says Dr. Pelet of HeiQ’s Scientific

Advisory Board.

“HeiQ strives to help improve the lives of

people through bringing breakthrough innovations

to textiles. We have pushed hard to bring the

HeiQ Viroblock technology to reality to assist

at this time of urgent need for society around

the world,” adds Centonze.

HeiQ Viroblock NPJ03 is a unique combination of

vesicle and silver technologies designed to

inhibit the growth and persistence of bacteria

and viruses. The HeiQ vesicle technology targets

lipid-enveloped viruses, such as coronavirus,

providing rapid virus deactivation, while the

HeiQ silver technology inhibits the replication

of both bacteria and viruses. HeiQ Viroblock

NPJ03 can be applied to a wide spectrum of

textile surfaces including face masks, air

filters, medical gowns, curtains, drapes and

more. HeiQ also has a range of highly

wash-durable antimicrobial and odor control

textile technologies, called HeiQ Pure,

combining silver-based and bio-based materials

for all fabric types.

Both 229E and Covid-19 are two of seven types of

human coronaviruses. Besides testing on human

coronavirus (229E), HeiQ Viroblock NPJ03 also

demonstrates dramatically improved reduction of

virus infectivity against Influenza types H1N1,

H5N1, H7N9, and Respiratory Syncytial Virus

(RSV).

https://www.nonwovens-industry.com/issues/2020-04/view_features/face-masks-industry-responds-to-crisis/

Sciessent Antimicrobial in Nextera Mask

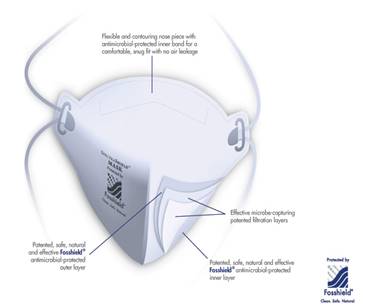

Agion Antimicrobial (AM)

by Sciessent,

a

U.S.-based provider of antimicrobial (AM)

solutions based on naturally occurring elements,

is incorporated into FDA cleared N95 respirator

masks, the type most in-demand in the fight

against the COVID-19 pandemic. As of March 31,

2020, over three million Nexera SpectraShield

9500 masks incorporating the Agion AM have been

delivered to healthcare facilities worldwide.

The Nexera SpectraShield surgical respirator was

cleared by NIOSH and received an updated 510(k)

from the Food and Drug Administration in 2015

with approved claims to inactivate viruses by

99.99% in five minutes and kill 99.99% of

bacteria in one hour. It has also been cleared

in Canada and the European Union.

"Following the

viral outbreaks of the early 2000s, Sciessent

engaged with university researchers, industry

partners and government organizations to

investigate the ability of Agion to inactivate

viruses," says Paul Ford, CEO, Sciessent. "Once

Agion AM's anti-viral efficacy was proven,

Sciessent worked with Foss Performance

Materials to develop a polyester fiber, named

FossShield, with Agion AM embedded into the FPM

fiber itself. The FPM media was then

manufactured into N95 respirator masks sold by

Nexera Medical."

Spectrashield Meets Efficiency Requirements

The filtration technology in the SpectraShield™

Series of antimicrobial respirator masks

formally passed penetration and resistance in

multiple testing at numerous independent testing

laboratories in the European Union. These tests

require the SpectraShield™ masks to be subject

to exposure of a quantity of particulate

aerosols at .3 micron in size at a specific

velocity rate. Upon the exposure of the

aerosols, the amount of droplets that penetrate

the mask are measured. In the European Union,

for the masks to be rated a FFP2 it must meet a

minimum of a 97% filtration rate, and for a

FFP3, it must meet a minimum 99% filtration

rate.

In addition to conventional testing for a

disposable respirator mask, the SpectraShield™

mask was also subjected to rigorous testing for

reusability in which each mask was tested for

filtration performance, inhalation and

exhalation minimum tolerances after the masks

had been subjected to severe clogging in a

dolomite dust test. Two of the SpectraShield

masks passed this rigorous reusability testing

to earn a classification of FFP2 RD and FFP3 RD.

The tests

conducted at these various independent

laboratories were conducted according to

national and international testing standard for

filtration and safety. All the independent

testing laboratories used in testing the

SpectraShield™ masks are recognized by the

applicable regulatory agencies in the European

Union.

Extensive toxicology testing has been performed

by AgION regarding the silver-copper zeolite

antimicrobial agent. Independent tests results

indicate the antimicrobial agent to be safe and

non-toxic causing no negative side effects,

conditions, or consequences.

Berry Global has New Material for Surgical Masks

Berry Global will

increase production of face mask materials. The

initiatives include additional capacity for the

production of face mask materials in North

America and a new material for face masks in

Europe. With demand outpacing current supply for

face mask filter media, the product development

team at Berry has responded to deliver

innovative solutions in a matter of weeks to

support the demand. These solutions include

pivoting existing manufacturing assets and

creating alternative materials for face masks.

Berry has

expanded its proprietary Meltex platform to add

meltblown capacity in Waynesboro, VA. The line

will make meltblown materials which will

ultimately be used in surgical-grade face masks

along with N95 and N99 respirators. This added

capacity will support the manufacturing of

approximately 200 million face masks annually.

Berry is also

launching an extension to its Synergex range of

products, Synergex ONE, a new media for face

mask applications. Developed to initially meet

the new face mask categories for general

population, the aim is to quickly bring the

media up to EN 14683:2019 standards for

surgical masks. The newly introduced Synergex

ONE provides a multilayer nonwoven composite

product in a single sheet, as an alternative to

traditional face mask layer structures. This new

material will be manufactured in Europe and

serve the European market and is available

immediately.

“This was

something that was of paramount importance in

the short term development,” says Cedric Ballay

EVP & GM for Europe in Health, Hygiene, and

Specialties for Berry. “Given the array of

materials currently being offered to the market,

we are proud to offer an alternative solution to

the traditional charged meltblown. We are now

continuing to push on with the development to be

able to pass BFE Type I and Type II testing with

this media.”

Features are

·

Multi-layer composite material – no lamination

needed

·

Filtration core of unique meltblown technology

·

Suitable for general use

NC State Develops

Two Polymer Spunbond for Masks Which Can Be Sewn

and is Washable

NC State’s Nonwovens Institute (NWI) is using

its two research and training pilot production

lines to produce face mask materials that will

be used to protect medical workers on the front

lines of fighting the effects of COVID-19.

Surgical face masks are made with nonwoven

materials, says Behnam Pourdeyhimi, executive

director of NWI, Wilson College of Textiles

associate dean for industry research and

extension and William A. Klopman Distinguished

Professor.

Because of the current critical need for masks

caused by COVID-19, Pourdeyhimi and his NWI team

created a new spunbond material that can serve

as an effective filter without the need for a

meltblown filtration layer. The unique fabric is

composed of two different polymer materials that

are combined to make a single fiber with

significant strength and bulk – and that shows

effectiveness in filtration similar to current

materials used.

“Because of the COVID-19 crisis, we took the

spunbond technology and created a new generation

of unique filters that have excellent filtering

capability and can potentially be reused after

cleaning with peroxide, or potentially alcohol

solution,” Pourdeyhimi said. “Because these

materials are strong, unlike classical meltblown

filters, they can also be cut and sewn by

traditional techniques.”

Typically, one meter of spunbond material

provides enough material for about 20 to 25

masks when using the current designs,

Pourdeyhimi said. One of the NWI’s production

lines started producing 2,000 meters of spunbond

material per hour, with the potential to create

some 20,000 meters of spunbond material in a

day. NWI currently has an agreement to provide

large amounts of spunbond nonwoven material to

Brooks Brothers, which will make masks at its

manufacturing facilities.

NWI’s other production line is a

state-of-the-art meltblowing pilot line that

will make the classical meltblown material for

N95 masks and surgical masks.

“We created a recipe for the production of

classical N95 respirator materials and will ship

those materials out for industrial partners to

convert these into respirators,” Pourdeyhimi

said.

The meltblown material takes a bit more time to

produce; Pourdeyhimi estimates that his

production line can make about 12,000 meters of

material in one work shift.

Thanks to support from across the university,

Pourdeyhimi says that NC State has ordered

machines that will allow the NWI to make

surgical masks in its Centennial Campus

facilities. Those machines should arrive in the

next month.

https://news.ncsu.edu/2020/04/a-necessary-filter/

Sandler Building a

New Non Wovens Line for Mask Media

Sandler Group is investing in a high-tech

nonwovens line for the production of nonwovens

for respirator masks. Production is already

scheduled for the middle of the third quarter.

The new line will allow Sandler to produce

nonwovens for the manufacture of up to 800

million masks. The investment totals a

single-digit million Euro amount.

Mitsui Chemicals has Expanded Melt Blown

Capacity

Mitsui Chemicals has

expanded its production facilities for meltblown

nonwovens at wholly owned subsidiary Sunrex

Industry Co., Ltd., starting operations at the

new facilities in January. The move comes as an

effort to respond to growing demand for

industrial-use meltblown nonwovens and will

increase the Mitsui Chemicals Group’s overall

production capacity for these materials by 50%.

Mitsui Chemicals

is positioning its nonwovens business as a

growth sector, making efforts here to supply

high-quality nonwovens as industrial materials

for a variety of applications. This includes use

in car seats (product name: TAFNEL), masks

(product name: SYNTEX) and agricultural sheets

(product name: SYNTEX). With particular respect

to SYNTEX MB nano, marketing efforts are going

toward use in filters and other such

applications that will take advantage of the

meltblown nonwovens line’s superfine fibers,

which are no more than several hundred

nanometers in diameter.

Three Layer Wipe is a Good Solution for

Coronavirus Mitigation

FiberTect is

a three-layer, nonwoven wipe that features an

activated carbon core sandwiched between

absorbent top and bottom layers.

“It is widely used as the primary dry

decontamination method in hospitals and

ambulances,” says Corey Collings, a training

specialist for First Line Technology, which

markets FiberTect. “Hospitals use it in bulk and

in rolls, and ambulances use it in a kit called

the FastGrab to do immediate decontamination of

patients contaminated with a wide variety of

substances.”

FiberTect was invented by Seshadri

Ramkumar,

a professor of chemical countermeasures and

advanced materials in the Texas Tech Department

of Environmental Toxicology.

He says the wipe’s structure is effective in

containing bodily fluids – like saliva and mucus

– through which viruses could be transmitted.

Its activated carbon also can absorb particles

transmitted in vapor phase through the air.

As a wipe or mitt, FiberTect holds great

potential for cleaning in settings where

transmission of the COVID-19 virus, is a

paramount concern.

It can be used to clean wet surfaces

contaminated with bodily fluids,” Ramkumar says.

“Highly porous carbon in the structure can trap

the vapors and aerosols in which microbes are

contained. The wipe structure is flexible and

can take the shape of the objects to be cleaned.

The three-ply structure without glue helps this

effective cleaning.”

FiberTect has previously been used successfully

by the U.S. military to decontaminate both

personnel and equipment, for oil spill cleanup

during the Deepwater Horizon spill in the Gulf

of Mexico, and by emergency response teams

across the country in dealing with highly

dangerous chemical substances, including

Fentanyl.

Its development and testing was sponsored by the

U.S. Department of Homeland Security and managed

by the Technical Support Working Group, Office

of the Assistant Secretary of Defense for

Special Operations/Low Intensity Conflict in the

U.S. Department of Defense. Product testing was

conducted by Lawrence Livermore National

Laboratory. FiberTect proved superior in

all testing results against 30 comparable

products for decontaminating against toxic

chemicals.

Large Non-Woven Demand to Mitigate Virus

Phil Mango of Smithers says that three major

nonwoven based products can help with the

current coronavirus crisis. These are:

-

Face masks

-

Anti-bacterial (skin) wipes

-

Disinfecting (hard surface

wipes)

In addition, general purpose medical nonwovens

like underpads, gauze, and medical garments may

all be useful in treating any increase in

patients.

Meltblown capacity globally is only about

360,000 tonnes today; about 30,000 tonnes of

unused capacity was available prior to this

crisis.

If SMS (spunbond/meltblown/spunbond) is

included, though, the current production

capacity increases to almost 5.0 million tonnes

with almost 1.0 million tonnes of excess

capacity. Not all SMS would be suitable, though.

Already, significantly increased pricing and

demand for meltblown in some regions has been

reported. The key here may be converting

capacity, turning sufficient nonwoven supply

into face masks.

Anti-bacterial wipes are used for disinfecting

skin, usually hands. It appears that hand

sanitizing wipes containing at least 60%

alcohol should kill COVID 19 (it is an

enveloped virus which usually is susceptible to

these disinfectants); but only testing will

confirm that. Already, most producers have

maximized production in anticipation of

increased demand. These are based on spunlace

nonwovens, and globally spunlace has over

700,000 tonnes of excess capacity, much of it in

Asia. Producers are ramping up production as

consumer and institutional demand has increased

rapidly.

Hard surface disinfecting wipes are also being

recommended, even though it appears most viral

transmission is through person-to-person contact

via airborne fluids. Cleaning and disinfecting

wipes, based on standard and SP (spunbond/pulp)

spunlace with a quaternary ammonium

compound-based disinfectant solution, again are

expected to be effective against COVID

19. Already, producers are ramping up

production.

Most nonwoven producers can rapidly increase

production of needed products; converters may

have a more difficult time, as they tend to run

closer to full and have a more difficult time

changing from one product to

another. Additionally, disinfecting/sanitizing

solution and chemicals may be in short supply

initially.

In nonwovens, the only challenge may be

obtaining the correct raw materials and

balancing other product commitments. For

example, while there is ample supply of spunlace

for wipes, this is not universally true.

Spunlace supply in North America is tight, and

Europe is balanced. So, logistics may play

a role.

For converters, it is more difficult as

converting lines are typically dedicated to

certain products. For wipes, the challenge is

obtaining disinfectant solutions, and probably

re-arranging/adding packaging assets; quality

control resources may also be stretched.

For face mask converters, there may be an actual

shortage of converting capacity, which may be

impossible to address short term. Existing lines

will have to be run at maximum capacity and

efficiency.

The actual nonwovens, spunlaid and spunlace,

have more production and more available

production in Asia; but converting has better

availability in North America and Europe,

especially for wipes. Similarly, disinfecting

solutions that are specifically designed for

killing viruses have more availability currently

outside Asia, though this may not be as much an

issue.

China is already in crisis mode and nonwoven

producers, and converters are running at maximum

output already. Additionally, other regions are

already supplying Asia.

Face masks have been used in Asia for other

reasons at a much higher frequency than in other

global regions for many years, so supply lines

are established already and a new peak demand

for face masks should be best addressed

here. North America and Europe will be starting

from a much smaller base.

Wipes are just the opposite; North America has

the highest production rates and utilization

rates for disinfecting wipes and should have the

easiest time addressing new peak demands; Asia

will have the hardest time and may rely on

liquid disinfecting solutions and paper or

textile cloths.