Coronavirus Technology Solutions

April 15, 2020

Chinese Production of Masks Accelerating Rapidly

Upstream Materials:

Non-Woven Fabrics

Robot Measures PM 2.5 and Other Pollutants

Throughout the

Hospital

Foot Sanitizers Can Prevent Virus Spread

Sindat Now Producing Efficient Masks with

Replaceable Membrane

Essity is Targeting 30 Million Masks per Month

Aerosol

Transmission is a Mode of Transmission for

COVID-19

Germs Killed by Mask

KAIST Nanofiber Membrane Masks Withstand Twenty

Washings

Repsilon Mask with Nanofibers with Better

Breathability

Nanofibers Could be the Key Elements for Filter

Materials in Face Masks or Respirators.

HVAC Systems

Transmit Virus

______________________________________________________________________________

Chinese Production of Masks Accelerating Rapidly

After a severe shortage of surgical masks and

N95 respirators during its own COVID-19 crisis,

China is now churning out face masks like

printing money says

Chiu-Ti Jansen,

the founder of China Happenings multimedia

platform. With the coronavirus sweeping

through Europe and the United States, every

Chinese person wants to sell you face masks.

By

one account, more than 12,000 new Chinese mask

production companies sprouted up in the wake of

the global pandemic.

As

work gradually resumes in China, Chinese

consumer industries brace themselves for

dwindling demands and cancelled orders

worldwide. Face mask production has attracted

the latest inflow of speculative capital.

Consequently, stock markets have staged

impressive "face mask rally".

A

large number of companies and capital

investments drove China's mask production to

reach 116 million daily by the end of February,

and the momentum continues. In Fujian

Province alone, the output increased from 10

million at the end of February to 21.19 million

in less than 20 days.

The

math is simple: each medical mask costs 0.6-0.7

yuan to produce and the wholesale price goes for

1.6 yuan, resulting in a profit margin of 1 yuan

apiece. One production line can make nearly

40,000 yuan (about $5,634) a day. If you run

five production lines, you can earn 200,000 yuan

(about $28,000) and recoup your investment of 3

million yuan in about 20 days.

In

China and South Korea, doctors treating COVID-19

typically wear full-body hazmat jumpsuits and

N95 masks. U.S. medical personnel, by contrast,

are often left to treat highly infectious

patients in standard cloth gowns and surgical

masks.

As

of March 28, the Czech Republic and

neighboring Slovakia were the only two countries

in Europe to impose mandatory mask-wearing. The

mandates have been credited for significantly

slowing down the spread of the virus. In Asia

where countries and regions, smarting from the

SARS experience, from China, Japan, Korea, Hong

Kong to Taiwan, wearing masks are part and

parcel of the combat strategies against the

coronavirus, especially when 25% to 50% of

infected population could be asymptomatic while

contagious.

As

the demand for medical supplies surges while

other consumer clothing lines slow, many Chinese

textile and apparel companies have switched to

producing protective garments. From February 1

to March 5, China added a total of 826 new

companies with "protective garments" in their

business scope. Compared with the same period of

last year, the growth rate of protective

clothing companies was 2,565%.

According to the China Garment Association, due

to the shifting business lines of many garment

factories, the production capacity of domestic

protective clothing is increasing, reaching

about 975,000 pieces per day.

Popular stocks in the mask and PPE sector

include Shangrong Medical (002551; production of

protective clothing); KraussMaffei Group

(600579; a subsidiary of ChemChina with a full

set of technology for the production of medical

melt-blown polypropylene, 90% market share);

Souyute Group (002503, R&D and production of

medical masks and protective garments); Gon

Technology (002768, mask melt-blown

polypropylene technology); Zisun Technology

(603601; N95 / N99 production line), Shandong

Dawn Polymer (002838; polypropylene melt-blown

material); and Nanjing Julong (300644;

melt-blown polypropylene technology).

The

high-flying mask and PPE rally in China, started

during China's own virus crisis, does not always

stand on steady legs. KraussMaffei's stock fell

to earth from its recent high at ¥9.81,

resulting in a paltry 2% year-to-date

appreciation as of April 2. At its high on

March 10, Nanjing Julong staged a 43% pop from

January 1, but it closed at ¥32.75 with a modest

10% YTD return.

Jihua Group (601718), a company dominating

China's military uniform market, quickly

switched to production of protective gear after

the epidemic. As of March 1, the company

produced 140,000 medical grade protective suits,

accounting for 40% of China's output. With

a foothold in Italy, Jihua is the only listed

company in the A-share market selling protective

garments and masks in Italy. After shooting up

36% from the beginning of the year to March 6,

Jihua's stock closed on April 2 with a 15% pop

year-to-date.

On

the other side of the spectrum, Dawn Polymer has

generated a 253% YTD return despite a recent

retreat from its high on March 10. Similarly,

Gon Technology took home a 48% YTD return, only

slightly off the 52% appreciation that it hit on

March 12. Generally the upstream material makers

appear to have a longer tail in stock rally than

downstream makers of masks and protective

garments.

Upstream Materials:

Non-Woven Fabrics

Generally the structure of a non-woven face mask

consists of three parts: an outer layer made

of polypropylene spun bond non-woven fabric;

polypropylene melt-blown non-woven fabric and

active carbon non-woven fabric are used as a

filter in the interlayer; and the inner layer is

made of polypropylene spun bond non-woven

fabric.

The

dislocation of the mask market has also created

a surge in demand for the polymer-based fabrics

used in the protective coverings. Competition

for polypropylene melt-blown material,

reflecting the technical threshold and

production process requirements, has led to the

soaring price.

One

ton of melt-blown cloth has soared by more than

400,000 yuan (about 56,000 US dollars), compared

with only 20,000 yuan before the crisis, a

20-fold increase.

With an estimated market share of 40% for the

specialty fabrics used in masks in China, shares

in Shenzhen-listed Dawn Polymer soared by 417%

in the six weeks following January 20, when the

Chinese were alerted to the person-to-person

transmission of the virus, sending the net worth

of its founder Yu Xiaoning and his wife to Rmb

16.8 billion yuan (about $2.38 billion), at

least on paper.

Medical grade non-woven makers such as Jiangnan

High Fiber (600527), Xinlong Holdings (000955),

Jihua Group (601718), Huamao (000850) and Mida

(000782) have also enjoyed the ride. In

addition, Sinopec (NYSE: SNP; 0386.HK;

600028.SH), one of China's leading petroleum and

petrochemical companies, indicated on February

25 that it would invest in 10 melt-blown cloth

production lines.

Minsheng Securities' recent research report

estimates that to support a work resumption rate

at 70%, based on one mask per person per day,

China would need 390 million masks per day. As

the domestic outbreak came under control,

overseas demands could give the mask rally a

second wind,

Many industry players believe that the current

demands in Europe and the United States are

accelerating, and China can still export a

meaningful amount after meeting its own

needs. But once the global epidemic situation

improves in the next few months, the surge in

production capacity could lead to a huge

surplus, and many companies will face the risk

of failure.

In

addition, quality issues abound as Chinese

companies tried to flood the global market with

face masks. The Netherlands recently imported

1.3 million FFP2 masks (equivalent to the N95

specification) from China, of which 600,000 were

found defective, forcing the government to

urgently recall them after distributions.

Reportedly these masks not only failed the FFP2

criteria, but also the less stringent FFP1

standard.

Robot Measures PM 2.5 and Other Pollutants

Throughout the

Hospital

In

Hong Kong, 687 miles from Wuhan, robot Temi is

the star of Hong Kong Children Hospital, Queen

Elizabeth Hospital, Yan Chai Group, Sheng Kung

Hui Group, and more than 50 nursing homes.

Families restricted from visiting their parents

during the epidemic rely on Temi to physically

move to the elders' bedside and initiate a video

conference.

Roy

Lim, Vice President of Tung Hing Automation that

invests in Temi and distributes the bots in Hong

Kong and China, told CapitalWatch that sales

have spiked since January. Armed with a

touchscreen, Alexa technology, a built-in sound

system and a tray for phone charges, Temi takes

the temperature of visitors at the entrance of a

senior center or a hospital and patrols in order

to locate random people and measure their

temperatures. Upon sensing an "object" reaching

38 Celsius or more, Temi will snap a picture and

email it to the nurse. As one of Time

Magazine's 100 Best Inventions of 2019, Temi is

the creation of Robotemi, an Israeli company

headquartered in New York with a manufacturing

base in Shenzhen.

At

a cost-effective price of $1,999 per unit, Temi

relies on an in-house

multi-layer LIDAR technology that would cost

competitors (e.g., Pudubot, Yunji's Run) $7,000

per bot to procure from German or American

producers. Temi's open Android SDK system also

allows customers to customize with additional

applications and connected sensors.

For

example, with merely a set of Indoor Air Quality

sensors attached, Temi can monitor the entire

hospital's PM2.5, carbon dioxide, formaldehyde,

temperature, humidity and even smoke particles

in every room and report them in real-time to

facility management.

During the current virus crisis, Shenzhen-based

Broadcare dispatched its robots that administer

configured intravenous injections to facilitate

chemotherapy, including cutting ampoules,

opening vials, shaking, disinfection, suction,

injection and other operations. These robots

are also taking care of air purification,

temperature control, and waste recycling and

disposal. This reduces the risk of occupational

injuries when medical personnel's movements are

restricted by heavy protective gear.

But

Zhang Jianwei, Professor of the Department of

Informatics at the University of Hamburg and the

world's leading expert on robotics, says

that

currently the levels of robots' senses,

movements, endurance, and flexibility are not

sophisticated enough to support complex tasks

such as intubation or modified rapid sequence

induction which poses high infection risk to

medical professionals.

Foot Sanitizers Can Prevent Virus Spread

A small study from China indicates that the coronavirus can

be found in the air up to 13 feet from patients

in a hospital. The virus was also found to

linger on hospital staffers’ shoes and may be

spread by walking in contaminated shoes.

“The aerosol distribution characteristics …

indicate that the transmission distance of

[COVID-19] might be 4 m (more than 13 feet),”

the report says. Testing was done in areas that

held a total of 37 virus patients.

“Furthermore, half of the samples from the soles

of the ICU medical staff shoes tested positive,”

the researchers wrote of samples taken at

Huoshenshan Hospital in Wuhan, China.

“Therefore, the soles of medical staff shoes

might function as carriers.”

High levels of the virus were also found

on frequently touched surfaces such as

trashcans, bed rails and computer mice.

The research was posted online in the CDC’s Emerging

Infectious Diseases Journal

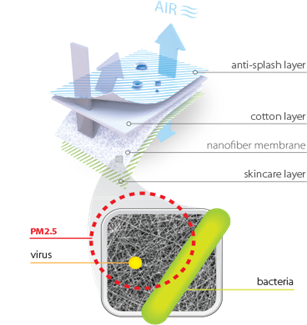

Sindat Now Producing Efficient Masks with

Replaceable Membrane

This major Czech company has developed a

comfortable cotton mask with a replaceable

membrane with high virus capture efficiency. The

mask is washable. A package consists of a mask

and 10 membrane inserts at a price around 10

Euros. It is recommended that the membranes be

worn only once but McIlvaine contacted company

officials who agreed that with a day of limited

use the membrane could be used a second day.

The cost per wearing could therefore be

well below 1 euro.

Essity is Targeting 30 Million Masks per Month

Hygiene and health company Essity has commenced

production in Sweden of surgical masks for use

by healthcare providers. The development has

been in close dialogue with the Swedish

government and the National Board of Health and

Welfare. The aim is to deliver the first masks

within the next few weeks.

The

Swedish production facility has the capacity to

produce three million masks a month. Essity has

also purchased a machine for large-scale

production of surgical masks which has a

production capacity of 30 million masks a month.

The machine is expected to be operational after

the summer. Preparations to manufacture face

masks are also under way at several of the

Group’s plants in other countries.

Aerosol

Transmission is a Mode of Transmission for

COVID-19

Results

indicate that aerosol transmission is a

potential mode of transmission for coronaviruses

as well as influenza viruses and rhinoviruses.

Published studies detected respiratory

viruses such as influenza and rhinovirus from

exhaled breath, and the detection of

SARS-CoV and MERS-CoV from air samples (without

size fractionation) collected from hospitals

treating patients with severe acute respiratory

syndrome and Middle East respiratory syndrome,

but ours demonstrates detection of human

seasonal coronaviruses in exhaled breath,

including the detection of OC43 and HKU1 from

respiratory droplets and NL63, OC43 and HKU1

from aerosols.

Findings indicate that surgical masks can

efficaciously reduce the emission of influenza

virus particles into the environment in

respiratory droplets, but not in aerosols.

https://www.nature.com/articles/s41591-020-0843-2

Germs Killed by Mask

Pintler

Medical LLC claims to have created a mask that

kills the germs with which it comes into

contact,

reports Fox

10 Phoenix.

It takes

quite the process for Pinter's masks to be ready

to destroy germs. The masks are made with a

cotton twill that is transformed to a

polypyrrole after a 13-hour process.

Since polypyrrole is anti-microbial and

anti-bacterial, these masks will kill germs and

viruses exhaled by the person wearing them. The

masks are rather sustainable, as they can be

washed and reused without sacrifice to the

fabric's germ-killing capabilities.

The masks are being sold for $35 a piece at

Summit Male Medical in Tempe, Arizona. Since

sales began, the business has sold out of the

masks at least once, but hopes to get more masks

in stock each week

KAIST Nanofiber Membrane Masks Withstand Twenty

Washings

Engineers at KAIST, one of South Korea’s finest

technology institutes, have now developed a

washable filtering material that can be used

within face masks. It can withstand at least

twenty hand-cleaning cycles without losing its

ability to trap fine dust particles. The

material, placed on appropriately designed face

masks with sturdy frames, lets the entire device

maintain its original shape through the washes.

According to the KAIST researchers, in their

tests the mask could continue filtering up to

80% of 600 nanometer-wide particles even after

4,000 bends. Once the mask has been washed

enough times to start losing its filtration

qualities, the filter material can be swapped

out for a new sheet without having to throw out

the rest of the mask.

Within the material are nanofibers, with a

diameter of between 100 and 500 nanometers, that

are arranged perpendicularly to each other via a

novel insulation block electrospinning process.

This creates a fine mesh that lets air through

while blocking very fine particles. Moreover,

the material is highly water resistant and so

dries out quickly before being used again.

Repsilon Mask with Nanofibers with Better

Breathability

Respilon®

Professional Halfmask provides ultimate

protection against viruses, bacteria, dust,

smog, emissions and other airborne particles

thanks to a special designed filtration layers

using nanofibers.

The nanofiber filtration layer in the R-mask, is

the highest dense filter on the market but still

provides 3x better breathability and 5x higher

filtration efficiency then the normally

required. And that is why R-mask is efficient

but comfortable to use at the same time.

https://www.respilon.com/products/professional-halfmask/home/

Nanofibers Could be the Key Elements for Filter

Materials in Face Masks or Respirators.

Nanofibers have a very high surface area per

unit mass that enhances capture efficiency and

other surface area-dependent phenomena that may

be engineered into the fiber surfaces (such as

catalysis or ion exchange). They could enhance

filter performance for capture of naturally

occurring nanoparticles such as viruses, as well

as micron-sized particles such as bacteria or

man-made particles such as soot from diesel

exhaust.

Nanofiber media significantly reduced mask

airflow resistance and resulted in more of the

exhaled air from the manikin passing through the

face mask as opposed to by passing the filter

and going around the edges

https://iopscience.iop.org/article/10.1088/1757-899X/460/1/012013

HVAC Systems Transmit Virus

Scientists believe opening windows in buildings,

including our homes, may prevent the spread of

the coronavirus,

Experts in health, the built environment and

microbiology at the University of Oregon and the

University of California, Davis, made the

recommendations by reviewing existing studies on

germs including SARS-CoV-2 (the virus which

causes COVID-19 disease).

The humidity of a building, the team said, may

also affect the spread of infections

like COVID-19. The limited data available on

SARS-CoV-2 indicates it is active longest on

plastic surfaces at a relative humidity of 40

percent, with an average half-life of 15.9

hours, and shortest in aerosol form with an

average half-life of 2.74 hours with a relative

humidity of 65 percent.

This is supported by evidence suggesting

viruses, including coronaviruses, struggle to

survive in typical indoor temperatures and at a

relative humidity of above 40 percent.

Targeted in-room humidification could therefore

be considered as a means for preventing

COVID-19, while remembering that humidity above

80 percent could create its own health problems,

the team advised.

Considering the potential use of air filtration

systems, the authors found the majority of

viruses, including coronavirus, are too small to

capture bugs like SARS-CoV-2 and "no filter

system is perfect."

Those with air delivery systems should take care

not to recirculate indoor air which "could

potentially increase the transmission

potential." Boosting airflow rates could

meanwhile risk sending germs into the air from

surfaces and "increase the potential for

contamination throughout the building by

distributing indoor air more quickly, at higher

velocities and volumes, potentially resuspending more ultrafine particles."

Keeping air filters properly installed and

maintained could help to minimize the spread of

SARS-CoV-2, according to the team who stressed

"it is important to understand that filters

should not be assumed to eliminate airborne

transmission risk."

They also looked at data on other members of the

large coronavirus family of bugs which trigger

severe acute respiratory syndrome (SARS) and

Middle East Respiratory Syndrome (MERS). They

published their findings in the journal mSystems.