Coronavirus Technology Solutions

April 6, 2020

The U.S. Forcing 3M to Ship

Masks from Offshore Plants to

the U.S.

The Mask Market Could Soar from

a few billion per year to

hundreds of billions

Studies Document the Air

Transmission of the Virus

Halyard Proposal for Mask Making

Equipment Anticipating a

Pandemic Rejected in 2018

More than 40 Designs of Facemask

Available from Halyard

H&M Making N95 Masks through

Chinese Plant

Honeywell to Produce 20 million

N95 Masks per month in the

Phoenix and RI Plants

3M Targeting 2 billion N95 Masks

per Year by Early 2021.

Keeping Score on Medical and N95

Mask Production

Shortage of Meltblown Fabric for

Face Masks

Sinopec can Make 5 million N95

Masks per day

_______________________________________________________

The U.S. Forcing 3M to Ship

Masks from Offshore Plants to

the U.S.

The Trump administration is

trying to use its wartime powers

to cut off 3M’s ability to

export face masks abroad, as

well as claim more of the masks

the company manufactures in

other countries for use in the

United States. Such a policy

would be a dramatic expansion of

the U.S. government’s reach as

it seeks to procure much-needed

protective gear for American

health care workers.

But some trade and legal experts

fear new mandates could

backfire, causing other

governments to clamp down on

exports of masks, ventilator

parts and pharmaceuticals that

the United States desperately

needs. They have also questioned

whether the Defense Production

Act gives the government the

authority to commandeer goods

made beyond United States

borders.

In a statement on Friday, 3M

said that the administration had

requested that 3M increase the

amount of respirators the

company imports from its

overseas operations into the

United States, and that 3M was

complying. Earlier this week, it

secured approval from China to

export to the United States 10

million N95 respirators the

company makes in China, it said.

The company added that the

administration had also asked 3M

to stop exporting respirators

that are manufactured in the

United States to Canada and

Latin America — a request it

said carried “significant

humanitarian implications” for

people in those countries. (this

is the evaluation covered in the

McIlvaine presentation during

the April 2 webinar which

provides a metric to make these

decisions without the need for

making humanitarian decisions

arbitrarily)

The Mask Market Could Soar From

a Few Billion Per Year to

Hundreds of Billions

At a choir practice in a

Washington State Church in

February precautions including

sanitizing everything and social

distancing were taken during the

two hours when 60 people

assembled.

Yet 45 of them contracted

the coronavirus. The conclusion

was that the act of singing

created an air transmission

route which was deadly. Hundreds

of Diamond Princess passengers

were not infected until they

spent weeks in their cabins

breathing the air from a common

HVAC system.

When the air transmission of

droplets smaller than 5 microns

is accompanied by interaction of

individuals who may not show

symptoms you create a situation

where masks become very

important. It is not surprising

that the Chinese death toll per

capita is very small compared to

Italy. For Chinese efficient

masks have been purchased for

years.

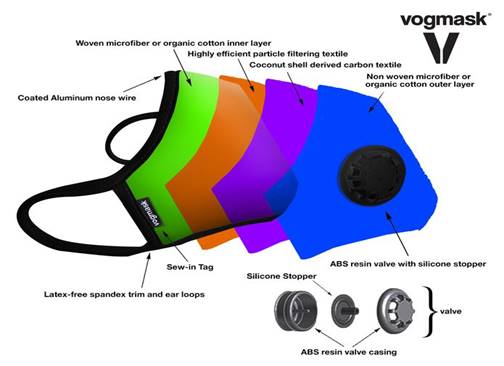

Vogmask opened its first retail

store in China in 2013.

This U.S. based company

had all the needed testing on

efficiency and resistance done

by Nelson laboratories.

These stores have the aura of a

sportswear store elsewhere in

the world. The masks sell for

$33 but can be washed 20 or more

times.

If

just ten percent of the world’s

population wore these masks that

would be 800 million wearers

With 20 wearings the cost

per wearing would be $1.50.

This alone would create a

$1.2 billion per day market or

$438 billion per year.

But

the poorer people could also be

wearing effective masks. China

is making N95 quality masks with

a nanofiber laminate on a cotton

backing.

The masks can be washed

at least 20 times at a cost per

day of just 15 cents.

If

2 billion people were wearing

these masks the cost would be

$300 million per day. Or $109

billion per year.

This would create a

market of over $500 billion per

year for mask makers. Based on

the cost of a life lost at $50

million this expense can be

justified if just 10,000 lives

are saved per year.

The

question for media and mask

makers is how long will this

boom last? The answer is very

likely 36 months and very

possibly permanently. It is

expected that the southern

hemisphere will experience an

epidemic during the northern

summer. Then infected

individuals will travel North

and there will be a spike in the

winter of 2020-21.

The

practice of wearing masks is

likely to be permanent for the

following reasons

·

Fear of another pandemic with a

new virus

·

Realization that there are

millions of cases of flu each

year and some can be prevented

·

The

emotional phenomena

which could cause an

exaggerated view of the risk

similar to fear of being eaten

by a shark if swimming in the

ocean.

·

Demonstration of compassion –

not wanting to infect anyone

with anything

The

nanofiber laminates create all

sorts of possibilities. There

are also new designs available

which provide a permanent mask

with replaceable media.

At least one Chinese

company is offering this design.

Exxon Mobil just announced a

design which provides improved

coverage of

the nose and mouth in a

structure which can withstand

repeated sterilization. A

replaceable cartridge with N95

efficiency is utilized.

Exxon Mobil is waiting for FDA

approval and then hopes to

produce 40,000 masks and

cartridges per hour.

Studies Document the Air

Transmission of the Virus

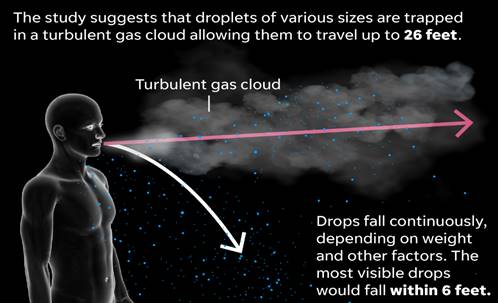

Air

contaminated with the COVID-19

virus might travel four times

farther than the 6 feet the

CDC asks we distance ourselves,

according to a recent study.

The study

published in the Journal

of the American Medical

Association found that

under the right conditions,

liquid droplets from sneezes,

coughs and just exhaling can

travel more than 26 feet and

linger in the air for minutes.

Findings such

as these may have some bearing

on the CDC's

recommendation on Friday that

Americans wear non-surgical face

masks in public —

especially in places "where

other social distancing measures

are difficult to maintain."

Halyard Proposal for Mask Making

Equipment

Anticipating A Pandemic

Rejected in 2018

In

September 2018, the Trump

administration received detailed

plans for a new machine designed

to churn out millions of

protective respirator masks at

high speed during a pandemic.

The

plans, submitted to the

Department of Health and Human

Services (HHS) by medical

manufacturer O&M Halyard, were

the culmination of a venture

unveiled almost three years

earlier by the Obama

administration. But HHS did not

proceed with making the machine.

The

project was one of two N95 mask

ventures — totaling $9.8 million

— that the federal government

embarked on over the past five

years to better prepare for

pandemics.

The

other involved the development

of reusable masks to replace the

single-use variety.

The Halyard contract was part of

an explicit strategy to ensure

we could surge mask production

in the next crisis,” said Nicole

Lurie, who was the HHS assistant

secretary for preparedness and

response under Barack Obama.

The projects did not

proceed. The company is

expanding N95 production and may

consider this approach as part

of the program.

More than 40 Designs of Facemask

Available from Halyard

The various designs from Halyard

contain features which might be

more widely adapted in the

pandemic era.

One with an expanded

chamber would assumedly offer

more surface area and therefore

less resistance. So that a more

efficient media could be used

with no more pressure drop than

the standard mask.

HALYARD* Blue Level 1 Surgical

mask meets all five ASTM

requirements for level 1

protection and comes with an

expanded chamber to provide the

user with additional space.

Halyard also has a high

filtration face mask with 97%

BFE and PFE ratings

H&M Making N95 Masks Through

Chinese Plant

Sweden’s H&M, the world’s

second-biggest fashion retailer,

said on Friday it had started

production of protective face

masks for hospital staff and

would ship the first batches to

Spain and Italy.

“At

this first stage, 100,000 face

masks will be produced and ready

for delivery on April 2. Half

will go to Italy and half to

Spain. It is a factory in China

that makes the masks,” a H&M

spokeswoman said in an email.

H&M

in early April said it was

looking into using its supply

network to source personal

protective equipment for

hospitals to help curb the

spread of the coronavirus.

The

masks are of the N95/FFP2

standard that protects from the

droplets through which the virus

spreads.

Honeywell to Produce 20 million

N95 Masks per Month in the

Phoenix and RI Plants

Honeywell announced that it is

adding manufacturing

capabilities in Phoenix to

produce N95 face masks in

support of the U.S. government’s

response to the novel

coronavirus (COVID-19).

The company’s Phoenix expansion,

coupled with previously

announced new production in

Rhode Island, will allow

Honeywell to produce more than

20 million N95 disposable masks

monthly to combat COVID-19 in

the U.S. New manufacturing

equipment to support the effort

will arrive in Phoenix beginning

this week.

“We at Honeywell are proud of

our role in providing essential

equipment to the first

responders and medical

professionals we are relying on

during this crisis,” said Darius

Adamczyk, Honeywell chairman and

chief executive officer. “We

have moved quickly to expand our

production capacity for N95

masks globally and are pleased

to announce our second new U.S.

manufacturing line to supply the

Strategic National Stockpile.”

Honeywell anticipates that the

new mask production line in

Phoenix will create more than

500 new jobs in Arizona. The

company has already begun

recruiting, hiring and training

manufacturing workers on the

site. Today’s announcement

brings the total number of U.S.

jobs created by Honeywell’s new

mask manufacturing capabilities

to more than 1,000.

The N95 face masks will be

delivered to the U.S. Department

of Health and Human Services to

contribute to the American

stockpile for use to support

health, safety and emergency

response workers. The Phoenix

facility will prioritize

fulfilling the U.S. government’s

procurement, but it will also

have the capacity to produce

face masks for U.S. states and

American healthcare and

emergency response

organizations.

Honeywell’s production expansion

will also support additional

American businesses, including

industrial equipment providers

and raw materials suppliers. The

company is collaborating with

state and local officials to

ramp up production efforts and

support hiring and training.

Honeywell’s Phoenix Engines

campus is one of the company’s

largest, and since 1950 has been

dedicated to the design and

manufacture of propulsion

engines and auxiliary power

units for a variety of

commercial and military

aircraft. The facility will

continue its aircraft technology

manufacturing operations

alongside the new protective

gear production.

3M

Targeting 2 billion N95

Masks per year by Early 2021.

In

early 2020 health officials

worried there were not nearly

enough of them. In early March,

officials from the U.S.

Department of Health and Human

Services said the country had

only about 35 million of the 3.5

billion N95 respirators needed

in the event of a full-blown

pandemic.

3M

doubled global production to 1.1

billion per year from about 400

million per year, and the

company said in late March it

plans to double production again

to 2 billion within 12 months.

The

explosion of face mask demand

could provide a small boost for

3M, which reported sales of

about $32 billion in 2019. The

company does not break down the

actual size of its face mask

business, but some Wall Street

analysts estimate 3M sold

anywhere from $100 million to

$325 million in face masks prior

to the outbreak of the disease.

The outbreak could add another

$300 million in sales, said one

analyst.

This

would be only a tiny portion of

3M’s overall business, but the

importance of the product still

has focused a tremendous amount

of attention on the company.

Keeping Score on Medical and N95

Mask Production

Information on mask production

around the world is voluminous,

confusing and inconsistent.

Here are some of the

latest figures.

Keeping Score on N95 Masks –

Millions Produced

|

Day |

Month |

Year |

|

|

Sinopec melt blown |

8 (May) |

240 |

2,880 |

|

3M in future |

5.6 |

167 |

2,000 |

|

U.S Need |

9.7 |

291 |

3,500 |

|

Amer. Mfgrs. now |

1.66 |

50 |

600 |

|

Honeywell in future |

0.66 |

20 |

240 |

The

Sinopec facilities can make

either medical masks or N95

masks. So it is not certain what

percentage is devoted to N95

production at any one time.

Keeping Score on Medical Masks –

Millions Produced

|

Entity |

Day |

Month |

Year |

|

China - March 2020 |

200 |

6000 |

72,000 |

Shortage of Meltblown Fabric for

Face Masks

Currently, of the 200 million

masks China makes a day, only

600,000 are N95 standard masks,

used by medical personnel,

according to the National

Development and Reform

Commission, a state planning

body.

This is

out of date as per the new

Sinopec capacity as shown above.

Provincial regulators have

granted dozens of new licenses

to open additional factories

capable of producing top-grade

masks, including those that meet

the standards for use by

health-care professionals.

But this ambitious effort has

run into a bottleneck. Both the

masks made for medical personnel

and for consumer purchase

require a once-obscure material

called melt-blown fabric. It's

an extremely fine mesh of

synthetic polymer fibers that

forms the critical inner

filtration layer of a mask,

allowing the wearer to breath

while reducing the inflow of

possible infectious particles.

"We're talking about fibers

where one filament has a

diameter of less than one

micron, so we are in the nano

area," said Markus Müller, the

sales director at German

company Reicofil,

a major provider of melt-blown

machine lines. And there's now a

global shortage of melt-blown

fabric due to the increased

demand for masks — and the

difficulty in producing this

material.

Costing upward of 3.8 million

euros ($4.23 million) apiece,

the machine that creates this

fabric melts down plastic

material and blows it out in

strands, like cotton candy, into

flat sheets of melt-blown fabric

for face masks and other

filtration products. A similar

line of machines can create a

related kind of fabric, called

spun-bond fabric, also used in

face masks and in medical

protection suits worn by

health-care workers.

The machines are not easy to

make because of the exacting

precision required, says Müller:

"You need to stretch these

fibers by hot air, and [the air]

needs to be in perfect condition

over the width of the machine.

Sinopec Can Make 5 Million N95

Masks Per Day

In early March, Sinopec

Corp, China's leading energy and

chemical company, put its first

meltblown nonwovens line into

operation at its Yanshan factory

in Beijing. The Yanshan factory

is a converted 3600-square-meter

old warehouse that has found new

life as a global production base

following the challenges brought

by the coronavirus outbreak.

The 14,400-ton capacity Yanshan

facility is one of Sinopec's

two meltblown nonwoven fabric

assembly bases and is co-managed

with China National Machinery

Industry Corporation. The base

has two nonwoven production

lines and three spunbond

production lines and can produce

up to four tons of meltblown

fabric for 1.2 million N95

disposable masks or six tons for

six disposable masks per day.

The new facility also takes

advantage of Sinopec's

integrated upstream supply-chain

by sourcing local materials from

Yanshan and support from the

on-site synthetic resin

production line.

"It normally takes about half a

year to complete the

construction of a 10,000-ton

meltblown fabric factory - We

have done it in 12 days, 48

hours ahead of schedule. In a

challenging time like this,

saving 48 hours means that we

can produce an extra 12 million

disposable masks," says Lv

Dapeng, spokesperson of Sinopec

Corp.

The largest medical material

supplier in China, Sinopec is a

significant supplier of

polypropylene, a key component

in the production of disposable

masks for medical use.

The new assembly line will

ensure a stable supply of

medical supplies, such as masks

and clothing, can be distributed

across the nation and

worldwide.

"We are privileged to support

those who are protecting us from

the virus. Sinopec will utilize

all of our resources to ensure

supplies to the frontline are

guaranteed," says Dapeng.

Sinopec's other eight meltblown

nonwoven lines in Yizheng, Jiangsu are

currently under construction and

are expected to enter

operational by mid-April.

Due to the global spread of the

virus, some countries and

regions are still facing a

shortage of face masks, which

led Sinopec to decide to build

16 melt-blown nonwoven

production lines, including 4

lines at Yanshan Petrochemical

Company and 12 lines at Yizheng

Chemical Fibre Company.

Specifically, 2 production lines

of the former went into

operation on March 8 and 8

production lines are expected to

be in operation by Mid-April.

With all 16 melt-blown nonwoven

production lines in production

by May, Sinopec will help

increase the output of disposal

face masks by 10 billion with an

annual production capacity of

10,000 tons. By then, Sinopec is

expected to become the world’s

largest melt-blown nonwoven

manufacturer, making further

contributions to the global

heath.