UTILITY E-ALERT

#1454– January 24, 2020

Table of Contents

CLIMATE CHANGE

COAL – U.S.

Wyoming and Montana challenge denial of Millennium Bulk Coal Terminal Permit in Supreme Court

Dairyland Power Cooperative to retire Genoa Station #3 in 2021

Two

Large Coal-fired Power Plant retirements in 2020 in Kentucky

COAL – WORLD

·

Global activists urge Bangladesh PM

to scrap Plans for Coal-fired Power Plants

·

Indian Power Utility lobbies to weaken Pollution

Standard

·

German Government negotiates Coal exit

but waters down Commission Recommendations

·

Modernization of the 680 MW Lignite-Fired

Power Station Kosovo B

BIOMASS

GAS TURBINES

WASTE-TO-ENERGY

NUCLEAR

_____________________________________________________________________________________________________________________________

CLIMATE CHANGE

The Opportunistic Antidote to the Climate Change

Doomsday Scenario

The U.S. Administration will support a trillion-tree planting campaign along

with many other nations. However, the U.S. still believes that warming may be

caused by solar activity and that increased CO2 levels are a result

and not cause of the warming. What if the U.S. government officials are wrong

and the doomsday predicters are right?

They say we are reaching a tipping point and it will be difficult if not

impossible to prevent the catastrophic floods and fires without immediate

cessation of fossil fuel burning.

Fossil fuel elimination will certainly threaten economic prosperity throughout

Asia. If Asian nations are not

participants any reductions in Europe and the U.S. will be insignificant.

The solution to this dilemma is a Doomsday antidote which is Opportunistic

Biomass Combustion and Sequestration. A UK consortium is already generating

a significant amount of its electricity from biomass burning and will be

distributing CO2 and hydrogen to industrial facilities and

sequestering the remaining CO2 underground.

In Canada the SaskPower Boundary Dam 3 coal fired plant has now supplied

3 million tons of CO2 for enhanced oil recovery.

So, there is no doubt that biomass combustion and CO2 sequestration

is a legitimate option. The

question is how costly will it be?

It will not be cheap but on the other hand if the doomsday believers are correct

then it could be the only option. This biomass combustion/sequestration will

“suck the CO2 out of the air.” Wind and solar are just neutral. So,

the biomass option is the antidote for the doomsday scenario.

The greater the impending doom the greater the amount of biomass which should be

grown, combusted and sequestered. But to be opportunistic why spend the money if

it is not needed. So, the opportunistic approach is to build and retain biomass

capable fossil fuel boilers. Should the coal fired boilers being retired in the

U.S. be scrapped or should they be mothballed and ready for conversion to

biomass firing if needed?

Should utilities reconsider scrapping the coal plants and building natural

gas-fired units? Or should they

design natural gas fired plants for eventual biomass gasification and

sequestration?

Should the Philippines make its new fleet of coal fired boilers biomass ready?

It is a major target of the trillion-tree initiative. There needs to be an

optimization of four initiatives.

·

Tree planting for long term sequestration (hundred years)

·

Biomass fuel growth with the most mass in the shortest amount of time

·

Biomass combustion

·

CO2 use and sequestration

Due to the uncertainties, the wise course is to spend modest amounts to make

combustion plants ready for biomass combustion while continuing to develop new

sequestration strategies including substituting CO2 for water in

hydraulic fracturing.

A biomass capable electricity generator becomes the highest-ranking choice with

wind, solar, hydro and other options falling behind. Biomass may never be burned

but if the doomsday scenario becomes part of the strategy then it is the

antidote.

Details on the strategies, projects, and on all coal-fired generators around the

world are included Utility Tracking

System.

http://home.mcilvainecompany.com/index.php/databases/42ei-utility-tracking-system

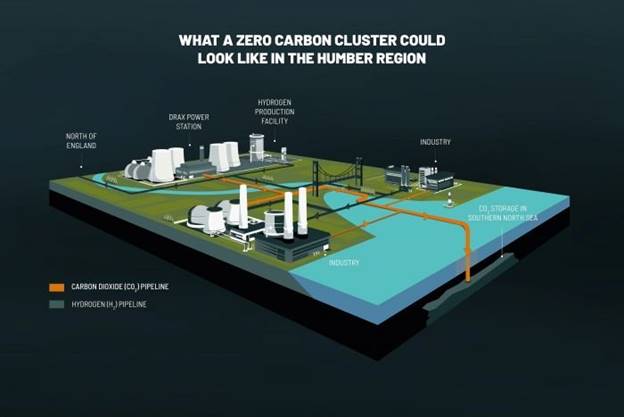

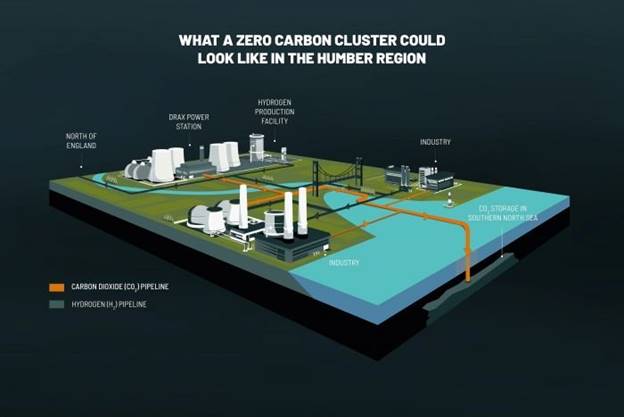

UK Coalition will sequester CO2

from Biomass Combustion

A coalition of industry, power and oil and gas firms in the U.K. are

collaborating on a net-zero industrial cluster that they believe will establish

a template for any country seeking a carbon-neutral economy. This was reported

by John Parnell in Greentech Media.

The coalition includes

Drax.

The company used to be best known for running the Drax Power Station, a

4-gigawatt coal-fired power plant in the north of England. Today 2.6 gigawatts

have been converted to biomass. The Drax Group has a spinoff in the U.S.

producing wood pellets, pumped hydro and a pipeline of gas power-plant

developments.

This mixed-fuel power complex on England’s east coast is at the heart of an

early proposal to send the U.K. on its way toward a net-zero economy. Its

biomass generators will be connected to carbon capture, utilization and storage

(CCUS) technology.

Meanwhile, National Grid, which runs the U.K. power transmission network and gas

distribution grid, will create a regional CO2 network offering industry and

petrochemical complexes down the Humber River the chance to feed into the pipe.

At that point, Norwegian oil and gas major Equinor gets involved, providing a

long-term home for that CO2 in the North Sea.

In tandem, the negative-emissions electricity at Drax will create hydrogen that

will be distributed down the Humber industrial cluster via a new network to be

developed by National Grid.

The timelines for the project, particularly the CCUS

component, could be shorter than expected. The companies involved include Drax,

Shell, and the utility SSE, NGV has developed the Endurance store — a saline

aquifer located 90 kilometers off the east coast of England in the Bunter

sandstone formation in the southern North Sea. It is ideally situated to

facilitate CCUS developments in the Humber region and could potentially be used

by other cluster developments, such as Teesside in the northeast of the U.K. or

Rotterdam in the Netherlands.”

SaskPower

Boundary Dam has now sequestered 3 Million Tons of CO2

The carbon capture and storage (CCS) facility at

SaskPower’s Boundary Dam (BD) Power Station had another good year in

2019, according to data released by SaskPower.

The facility prevented more than 616,000 tons of

carbon dioxide (CO2) from entering the earth’s atmosphere, even

though there was a scheduled shutdown that lasted about two months.

There was also scheduled maintenance in the second

half of November and the first week of December that took the facility offline.

It was also a year of milestones and firsts for CCS.

The CCS facility eclipsed the three-million-ton mark

for CO2 captured and sequestered on November 4. It took a little more

than five years to hit that mark.

The CCS facility also hasn’t had a lost-time accident

since it came online in October 2014.

“You see the size and the scope and the equipment and

the chemicals that we’re handling and all those sorts of things, and 24 hour a

day operation, 365 days a year, that plant has equipment running in,” said

Howard Matthews, the vice-president of power production at SaskPower.

The 20,000 HP Compressor inside the CCS facility also

went through its first overhaul and inspection last spring. “It was due for its

regularly scheduled five-year dismantle and inspection, and a 57-day outage to

allow us to take that compressor (apart),” said Matthews.

There have been some challenges. The boiler in Unit 3

has encountered tube leaks, because Matthews said the fuel the boilers burn

wears the tubes out. “After five years of hard run time on the BD 3 boiler,

we’ve seen a couple of tube leaks. Of course, when the boiler’s not operating,

there’s no flue gas and no steam for the CCS facility and it takes CCS offline,”

said Matthews.

There will be some scheduled maintenance at Boundary

Dam this year. They won’t be to the same degree as the two-month shutdown of a

year ago, but there will be regularly scheduled maintenance for cleaning work in

the tower, absorber and heat exchangers.

Nothing unusual is slated, which means there should

be very good performance in 2020, Matthews said.

“It does take a bit of time when you come offline,”

said Matthews. “Things cool down and you have to get the chemical back into spec

and the temperatures back correct, and then go back online with the

compressors.”

He believes there has been some really good progress

on the facility over the past five years. SaskPower’s game plan when it embarked

on the CCS facility was, first and foremost, to prove the technology and to show

it would work as intended. Matthews believes they have done that.

They also wanted to improve reliability.

“We’ve seen substantial improvement in reliability

with some of the work that we’ve done in the past couple of years,” said

Matthews.

Now their focus is surrounding cost reduction and

trying to get their costs for CCS as low as possible.

“The whole point of this is with reliability and cost

improvements, to give the best information that we can to the decision-makers

going forward. Those decisions won’t be made for some time. We continue to work

on reliability and reducing our costs,” said Matthews.

Trump backs Trillion Tree Initiative

President Trump, on

January 21, announced the United States will join the One Trillion Trees

Initiative. Trump made the announcement during an address to global business

leaders gathered for the annual event in Davos, Switzerland. "We're committed to

conserving the majesty of God’s creation and the natural beauty of our world,"

Trump said, adding that the U.S. "will continue to show strong leadership in

restoring, growing and better managing our trees and our forests.”

At the 4,000-megawatt Drax plant in the UK, biomass

is being burned as a replacement for coal.

Furthermore, the utility is funding a sequestration program with the goal

of permanently encapsulating CO2 underground.

When you combine the Trillion Tree Initiative and

biomass combustion and sequestration you have a program to actually reduce CO2

not just avoid emitting more. This means that there is no tipping point beyond

which there is no potential for carbon reduction. It is a good bet that our

views on climate change will be considerably different 20 years from now than

they are now.

If it turns out that the impacts of elevated CO2

levels are even worse than now anticipated the combination of planting, biomass

combustion, and sequestration is even more important. If it turns out as it did

in the case of dioxins where the harm was vastly over-estimated or ulcers where

the true cause turned out to be a virus then there is a flexible program, which

will respond appropriately. Here are the impacts on CO2 levels of the

various technologies.

|

Technology |

Impact on CO2 levels |

|

Wind and solar |

zero |

|

Coal combustion |

increase |

|

Additional tree planting |

decrease |

|

Equilibrium where a number of new trees

are offset by decaying trees |

zero |

|

Biomass combustion |

zero |

|

Biomass combustion and sequestration |

decrease |

So, the flexible program incorporates additional

tree planting until equilibrium is reached. Then dying trees are substituted for

fossil fuels. If more reduction is needed sequestration of the biomass combustor

emissions is undertaken.

In 2006, the Billion Tree Campaign was launched, by

the (UNEP) as a response to the challenges of global

warming,

The Billion Tree Campaign was handed over to the

Plant-for-the-Planet Foundation in December 2011, an organization that has been

participating in the Billion Tree Campaign since 2007. In December 2017,

following the discovery that there are more than three trillion trees on Earth,

the planting target was revised to a trillion trees and the Billion Tree

Campaign became the Trillion Tree Campaign.

One estimate found that this number of trees would

cancel out the last 10 years of CO2 emissions and sequester 160

billion tons of carbon. However, the

intergovernmental panel on climate change is even more positive. They estimate

that one trillion trees will store an

estimated 205 billion tons of carbon, or about two-thirds of the carbon that

humans have added to the atmosphere since the 1800s.

The problem with this approach is that 30 years from now in 2050 there will be

lots of trees dying and emitting CO2. However, at that time the

biomass can be harvested and burned in power generators. If the 500,000 MW of

new coal-fired capacity, which is built is designed to be biomass ready, it can

be converted making each of the generators carbon neutral. If this CO2 is

then sequestered, these generators would be as the UK describes it “sucking the

CO2 out of the air. They would be the only generator type which

actually reduces CO2.

What are the costs? The continuation of the coal-fired power program would net

a savings of $7.2 trillion over 30 years. This saving would primarily be in a

few Asian countries. The tree planting program would cost $700

billion resulting in a $6.5 trillion saving over the 30 years. For the period

2050-2080 the coal-fired power plants would be converted to burn biomass and if

necessary, also sequester CO2.

Sequestration would raise costs of electricity generation and make this approach

relatively more costly but only after 2050. Since biomass combustion and

sequestration is the only CO2 reduction option it can be employed if

necessary.

|

Activity |

2020-2050 |

2050-80 |

|

Tree Planting |

-$700 billion |

-$700 billion |

|

Saving with coal vs. more expensive generation options |

$7.2 trillion |

|

|

Net savings |

$6.5 trillion |

|

|

Biomass combustion with or without sequestration. |

Biomass combustion without sequestration would increasingly be

implemented. |

Sequestration would be an

alternative to other renewables and actually remove CO2 and

not just be neutral. |

In 2050 these biomass- ready coal-fired power plants would have already served

their purpose as coal generators. Their conversion to biomass would ensure that

the forestation approach is sustaining in terms of CO2 minimization.

However, if there are major improvements in the cost of wind and solar and no

need to reduce CO2 the

plants could be retired. But since they would be the only alternative for

dealing with dying trees, they will continue to be utilized.

Another option is to convert these plants to biomass combustion at an earlier date. There is optimism that the cost of sequestration can be greatly reduced through programs underway at Drax and other locations. If some of the most pessimistic forecasters are right and climate change becomes a crisis, then the biomass generation and sequestration becomes the only route to solve the problem since it reduces CO2.

The present CO2 level is 410 ppm. But a massive tree planting program

could have the effect of reducing CO2 by more than 1 ppm per year.

The net effect would be a 390 ppm CO2 level in 2050.

|

Initiative |

2020-2050

ppm CO2 |

2050-2080

ppm CO2 |

|

Existing |

410 |

390 |

|

New Coal and Other |

30 |

20 |

|

Tree Planting |

-50 |

0 |

|

Biomass Combustion at most former coal plants

and Sequestration |

0 |

-30 |

|

CO2 level in the atmosphere at end of period |

390 |

380 |

After 2050 solar and wind will be more cost effective particularly if energy

storage methods advance. The need for new coal-fired power plants will cease but

there will be other sources with the potential to add 20 ppm to the atmosphere

in the 2050-2080 timeframe.

In 2050 there will be a very large quantity of fuel contained in elderly trees.

They can be harvested and burned as fuel. The biomass would replace coal in

existing boilers. They would not

emit CO2 to the atmosphere if there is sequestration. New trees that

replace the old trees will continue to remove CO2. So, this

initiative would more than offset man-made sources and the CO2 level

could drop to 380 ppm in 2080.

CO2 sequestration has been commercially

practiced for decades. One use has been enhanced oil recovery. CO2 is

being piped long distances in many areas. Presently it is economic only if it

has a use such as recovering oil. The UK believes that new carbon capture

technologies will drive down the cost over the coming years. But whether it is

inexpensive or expensive, the situation is manageable in 2050 due to the ability

to suck out the CO2. This control provides flexibility. It will allow

construction of coal-fired power plants in India, the Philippines, Indonesia,

Bangladesh, and Vietnam and still achieve climate change goals.

NETL Project

Validates Geologic Storage of CO2 to boost Energy Production,

reduce Carbon Footprint

The carbon footprint created by industry and other

human activity in Big Sky Country — the area stretching across the Great Plains

and into Canada — can be reduced using technology pioneered by NETL

and partners at a leading research university.

Work completed as part

of the NETL-backed Plains CO2

Reduction (PCOR) Partnership demonstrates not only the ability to reduce carbon

dioxide emissions, it also enhances the efficiency of oil production, an

important consideration to bolster domestic energy production.

PCOR is one of the U.S. Department of Energy’s (DOE) seven

Regional Carbon Sequestration Partnerships (RCSPs), which have been laying the

groundwork since 2003 for large-scale geologic storage of CO2

in the United States as a means of mitigating effects of climate change while

still allowing for the efficient and affordable use of fossil fuels for energy

production.

RCSP activities, supported by NETL, have included assessments of geologic and

terrestrial storage potential in each region, followed by small-scale validation

tests and six large-scale (greater than 1 million metric tons) geologic storage

field experiments.

The Energy and Environmental Research Center (EERC) at the

University of North Dakota leads the PCOR Partnership. Throughout its

history, PCOR has engaged a membership of more than 120 partner organizations

drawn from industry, government and research institutions to foster carbon

capture, utilization, and storage (CCUS) deployment across a vast region.

The positive environmental impact of PCOR is significant. Stretching from

Missouri through the northern Great Plains to northcentral Canada, this region

possesses outstanding potential for widespread CCUS deployment because it has

significant geologic storage resources and an extensive fossil fuel-based

industry. Furthermore, several active CCUS projects in the region are already

setting an example for future work by demonstrating safe and effective carbon

management strategies with attendant economic benefits.

Another key achievement of the PCOR Partnership was its assessment and

monitoring of more than 6 million metric tons of CO2

storage associated with the enhanced oil recovery (EOR) operations, which inject

captured CO2 into oil

reservoirs to increase production, at Denbury Resources’ Bell Creek oilfield in

southeast Montana.

NETL-supported

Petra Nova Project celebrates Three Years of Sustainable Operation

The

world’s largest operating post-combustion carbon dioxide (CO2)

capture system Petra Nova celebrates its third anniversary January 10, 2020. The

project, supported by the U.S. Department of Energy (DOE) Office

of Fossil Energy and administered by NETL, is demonstrating how

carbon capture, utilization, and storage technologies can economically support

the flexibility and sustainability of fossil fuels at commercial scale.

Owned and operated by NRG Energy Inc. and JX Nippon Oil and

Gas Exploration Corporation, Petra Nova is located southwest of Houston

Texas and applies carbon capture technology to an existing unit at the

coal-fired W.A. Parish Generating Station.

Commencing operation in 2017,

the Petra Nova project addresses capture and

beneficial reuse of CO2

from coal-based electricity production. The project uses an advanced amine-based

process to capture CO2,

which is then compressed, dried, and transported for enhanced oil recovery (EOR)

at the West Ranch Oil Field in Jackson County, Texas, to boost oil production.

Using the Kansai Mitsubishi Carbon Dioxide Recovery (KM-CDR) Process©, the Petra

Nova project is designed to capture approximately 90% of the CO2

from a 240-megawatt equivalent flue gas slipstream — which is approximately 1.6

million tons of CO2

per year (assuming an 85% availability). Since beginning operations in January

2017, Petra Nova has captured more than 3.9 million short (U.S.) tons of CO2

and West Ranch Oil Field has produced more than 4.2 million barrels of oil

through EOR.

COAL – U.S.

EPA approves Utah’s Regional

Haze Plan

EPA

is proposing to take action pursuant to section 110 of the Clean Air Act (CAA or

Act) on State Implementation Plan (SIP) revisions submitted by the State of Utah

on July 3, 2019, as supplemented on December 3, 2019, to satisfy certain

regional haze requirements for the program’s first implementation period. The

EPA is proposing to approve the July 2019 SIP revision that provides an

alternative to best available retrofit technology (BART) controls for nitrogen

oxides (NOx) at the PacifiCorp Hunter and Huntington

power plants. The EPA proposes to find that the Utah NOx BART Alternative for

Hunter and Huntington would provide greater reasonable progress toward natural

visibility conditions than BART, in accordance with the requirements of the CAA

and the EPA’s Regional Haze Rule (RHR). In conjunction with this proposed

approval, EPA proposes to withdraw the federal implementation plan (FIP) that

addresses NOx BART for the Hunter and Huntington power plants. The EPA also

proposes to approve the December 3, 2019 SIP supplement that would require

reporting of all deviations from compliance with the applicable requirements

under BART and the BART Alternative, including the emission limits for Hunter

and Huntington.

Federal Register/Vol. 85, No. 14/Wednesday, January 22, 2020 / Proposed Rules

California’s Richmond City Council has approved an ordinance to phase out

storage of coal and petroleum coke in that city. The ordinance gives

Levin-Richmond Terminal Corporation on the Santa Fe Channel east of Point

Richmond and south of the Iron Triangle neighborhood three years to wind down

coal and coke storage operations. The terminal stores coal shipped from Utah

mines before export to Japan. Richmond City Mayor Mr. Tom Butt said “The coal

ordinance is created following complaints from the public about increased coal

dust in the air in parts of Richmond. It would govern only the storage of coal

in Richmond; it will not have any effect on transportation of coal through the

city by rail.”

Levin-Richmond Terminal is a dry bulk cargo marine terminal on the San Francisco

Bay in Richmond, California. It is privately owned by the Levin Richmond

Terminal Corporation. Levin Richmond Terminal Corporation began exporting coal

in 2013. It had already been exporting petcoke for decades. The petcoke comes

from the Phillips66 refinery to load onto boats headed for Australia and Europe.

Wyoming and Montana challenge denial of

Millennium Bulk Coal Terminal Permit in Supreme Court

Wyoming Governor Mark Gordon announced that Wyoming and Montana have jointly

asked the United States Supreme Court to hear a challenge to Washington State’s

denial of the proposed Millennium Bulk coal terminal in Longview in Washington.

Governor Gordon said that specifically, the two states seek to invoke the US

Supreme Court's original jurisdiction, which allows for disputes between states

to bypass lower courts and proceed directly to the US Supreme Court. Wyoming and

Montana argue that Washington's discriminatory denial of a Section 401 Water

Quality Certification for the coal terminal violates both the Dormant Commerce

Clause and the Foreign Commerce Clause of the United States Constitution. The

Commerce Clause to the US Constitution authorizes the federal government, not

states, to regulate interstate commerce.

Governor Gordon said that he remains hopeful that the U.S. Supreme Court will

act expeditiously and grant a hearing on this issue that is critical to the

state's economic interests.

The challenge stems from a 2017 decision by the Washington Department of Ecology

to deny permit applications to build a proposed coal terminal in Longview,

Washington called Millennium Bulk. Washington officials denied a Section 401

Water Quality Certification for the Terminal with prejudice, effectively killing

the project.

Dairyland Power Cooperative to retire

Genoa Station #3 in 2021

Dairyland Power Cooperative

announced that its Sustainable Generation Plan includes the retirement of the

coal-fired Genoa Station #3 in mid to late 2021. This decision also aligns with

our Sustainable Generation Plan and its focus on the continued addition of

renewable resources,” said Barb Nick, President. “The recently announced

approval by the Public Service Commission of Wisconsin for the

Nemadji Trail Energy Center in Superior gives us the added confidence

to take this next step to further diversify Dairyland’s resource mix and reduce

our carbon intensity.

It is desirable to determine the impact on flow and treat markets

It is a once through water system. Most of the flyash is sold but about

10’% has been landfilled.

As can be seen below there will be elimination of lime, urea, and activated

carbon as well as replacement bags.

plant name: Genoa

epa unit id: 1

Dairyland Power Cooperative

utility name: Dairyland Power

Cooperative

state: WI

county: Vernon

size MW: 345.6

plant startup: 1969

part addition: ESP, baghouse sized for ACI

part addition startup: 1992, 2010

part addition supplier: ABB

fgd startup: 2010

fgd supplier: Alstom

fgd architect: Sargent & Lundy

fgd reagent: lime

fgd process: dry

nox pc technology: SNCR

Mercury technology: ACI

Two Large

Coal-fired Power Plant retirements in 2020 in Kentucky

The Tennessee Valley Authority’s

Paradise Unit 3 near Drakesboro is scheduled to shutter this December while

Owensboro’s Elmer Smith Generating Station will cease operations in June.

At Paradise there will be lost revenues for

limestone, anhydrous ammonia, catalyst modules, and FGD nozzles.

plant name: Paradise

epa unit id: 3

new owner:

parent utility: Tennessee Valley Authority

utility name: Tennessee Valley Authority

state: KY

county: Muhlenberg

size MW: 1150

future plans:

plant startup: 1970

fuel specific: blend PRB/bit

part original equipment: Cold Side ESP

part manufacturer: American Standard

fgd startup: 2006

fgd supplier: Advatech

fgd changes to original: upgrade 2012

fgd reagent: limestone

fgd process: wet

fgd survivor company: Mitsubishi

fgd process efficiency: 98%

fgd scrubber vessel material: alloy 2205 with

superduplex alloy

nox pc technology: SCR

nox pc supplier: Alstom

nox pc startup: 2003

nox pc catalyst supplier: Cormetech

nox pc efficiency: 90%

nox pc ammonia type: anhydrous

nox pc ammonia supplier: LaRoche

At Elmer Smith the primary difference in the two units shutting down other than

size is that one has SCR and one has SNCR. The lost revenue will be limestone,

urea, and ammonia along with components such as FGD nozzles

plant name: Elmer Smith

epa unit id: 1

new owner:

parent utility: Owensboro Municipal Utilities

utility name: Owensboro Municipal Utilities

state: KY

county: Daviess

size MW: 151

future plans:

plant startup: 1964

fuel specific: Med Sulfur Bit

alternate fuel: None

boiler type: cyclone furnace

boiler manufacturer: Babcock & Wilcox

plant architect: Smith & Loveless

cooling type: once through, fresh water

part addition: ESP

part addition startup: 1993

part addition supplier: Wheelabrator

Fgd startup: 1995

fgd supplier: Wheelabrator

fgd architect: Smith & Loveless

fgd changes to original:

fgd reagent: limestone

fgd process: wet

fgd survivor company: Wheelabrator

fgd process efficiency: 90%

nox pc technology: SCR

nox pc architect: Sargent & Lundy

nox pc startup: 2003

nox pc catalyst supplier: Haldor Topsoe

nox pc ammonia type: anhydrous

nox pc injection system supplier: Wahlco

nox pc dampers supplier: Bachmann

nox pc expansion joints suppliers: Papco

plant name: Elmer Smith

epa unit id: 2

parent utility: Owensboro Municipal Utilities

utility name: Owensboro Municipal Utilities

state: KY

county: Daviess

size MW: 265

plant startup: 1974

fuel specific: Med Sulfur Bit

alternate fuel: None

boiler type: Pulverized Dry Tang Firing

boiler manufacturer: ABB Combustion Engineering

plant architect: Smith & Loveless

cooling type: once through, fresh water

part addition: ESP

part addition startup: 1994

part addition supplier: Wheelabrator

fgd startup: 1995

fgd supplier: Wheelabrator

fgd architect: Smith & Loveless

fgd reagent: limestone

fgd process: wet

fgd survivor company: Wheelabrator

fgd process efficiency: 90%

nox pc technology: SNCR

nox pc supplier: Hamon Research Cottrell

nox pc startup: 2003

COAL – WORLD

Global activists urge Bangladesh

PM to scrap Plans for Coal-fired Power Plants

Forty international civil society organizations, think tanks, and climate

movement platforms have urged prime minister Sheikh Hasina to withdraw the

approval of all coal-fired and other fossil fuel-based power plant projects.

In a petition sent to the prime minister, the organizations requested Hasina to

take steps to generate all power in the country from renewable energy by 2050,

according a press release.

Friends of the Earth,

350.org, Bank Information Centre, Oxfam

Bangladesh among the signatories of the petition, said the release was

issued by NGO Forum on ADB—a Philippines-based international

network of civil society organizations.

The 29 coal-fired power plants, if built, would emit 5.3 billion tons of

carbon-dioxide in their lifetime of 40 years, and would make the climate impact

worse for Bangladesh, according to the petition.

The petitioners raised high concern on the duty exemption of coal power plants.

Bangladesh compensated at least $ 4.45 billion in past 6 years and $ 1 billion

in fiscal year 2018–19 as capacity charge for stranded assets of the independent

power producers as much of generated power by them remained unused, they said.

They said that SS Power Limited, a coal-fired plant owned by the S Alam

Group, had alone got a duty exemption of Tk 3100.71 crore.

In the Paris Agreement of 2016, Bangladesh pledged to reduce greenhouse gas

emissions and to increase renewable energy use at 10 percent by 2021, but so far

met only 4 percent of that target as of November 2019, said the petitioners.

The petitioners also lauded Bangladesh for being the first country to adopt a

resolution in parliament declaring climate change a ‘planetary emergency.’ But,

they said, the decision to increase coal-based power plants is contradictory to

Hasina’s remark on the climate action and also against the nations’ climate

commitments.

Indian Power Utility lobbies to weaken

Pollution Standard

NTPC,

a publicly owned utility, which generates about one-quarter of India’s

electricity, is lobbying for a significant weakening of nitrogen oxide pollution

standards for coal-fired power plants built after 2017. Standards to protect

public health

were announced in 2015, with coal plants commissioned after 2017 not allowed to

exceed nitrogen oxides concentrations of 100 milligrams per cubic meter of air

(mg/Nm3). NTPC wants new plant pollution limits for nitrogen oxides

to be set at 450 mg/Nm3. The Modi Government is already seeking to

lift the nitrogen oxides limit on coal-fired power plants built between 2004 and

2016 from 300 mg/Nm3 to 450 mg/Nm3. NTPC is claiming

trials of nitrogen oxides pollution control in India have proved ineffective at

controlling emissions, a claim disputed by companies involved in the projects.

The revelation comes as coal-fired power plants, in breach of the December 2019

deadline for the installation of flue gas desulfurization

units, continue to operate

without penalty.

German Government negotiates Coal

exit but waters down Commission Recommendations

The German Government has agreed

to allocate €40 billion (US$44 billion) to support economic restructuring of the

four states affected by the closure of hard coal-fired power plants by

2035 and lignite

power plants by 2038. The deal provides for 2,800 megawatts (MW) of lignite

plants to be closed by 2022, 200 MW less than recommended by the coal exit

commission, but with no plants to be closed between 2022 and 2025.

The agreement also allows the

commissioning of the 1,000 MW Datteln 4 unit. The government is also proposing

to allocate €2.6 billion (US$2.9 billion) to RWE for lost revenues

on its plants and a further €1.75 billion (US$1.9 billion) for power utilities

in the east of the country. The deal provides for the demolition of six more

villages to cater for mine expansions but spares Hambach forest, but only as an

island surrounded by mining.

The weakening of the coal exit

commission’s proposed package has been criticized by former commissioners who

argue the government’s proposed legislation should be modified to reflect the

original recommendations. ClientEarth estimates up to 6,000 MW of

lignite plants could still be operating up to 2038.

The Cabinet of Ministers has

approved two new 300 MW coal-fired power plants in Norochcholai and two 300 MW

liquefied natural gas (LNG) plants in Kerawalapitiya amid serious concerns over

an impending power crisis.

Accordingly, Cabinet Co-Spokesperson and Information & Communications

Technology, Higher Education, Technology & Innovations Minister Bandula

Gunawardane revealed that two new 300 MW coal-fired power plants will be built

as an extension to the existing Norochcholai coal-fired power plant.

The former Power and Energy Minister Ravi Karunanayake initially brought the

proposal last year to add a 300 MW coal power plant to the Norochcholai facility

with a loan from China. .

The Cabinet also approved the installation of an LNG (bi-sectorial natural gas

plant) with a capacity of 300MW as a joint venture with Ceylon Electricity Board

(CEB) and India /Japan in Kerawalapitiya.

The lignite-fired power station “Kosovo B” near Pristina will be modernized, in

cooperation with the Government of Kosovo and under the direction of

Engineering Dobersek GmbH, supported by its consortium partners

Hamon Thermal Europe S.A., France and RJM Corporation (EC) Ltd.,

England, trading as RJM International.

This consortium has joined together to deliver the required technical and

commercial solutions as set out in the EU tender. The purpose of the contract is

to significantly reduce nitrogen oxide emissions (NOx from around

700-800 mg/Nm3 to less than 200 mg/Nm3 at 6% O2,

with SNCR), and dust emissions (from 300-700 mg/Nm3 to 20 mg/Nm3),

while improving plant efficiency to recover full load of 339 MWe per boiler, up

from around 292 MWe.

References in South East Europe—including projects financed by the World

Bank and the EU enable Engineering Dobersek to contribute with its

experience to this project in Kosovo.

The consortium leader, Engineering Dobersek (www.dobersek.com

) will coordinate the project and will be responsible for full management of the

site, the pneumatic ash handling system including necessary air supply.

Consortium partner Hamon Thermal will design and supply the Electrostatic

Precipitator filtration system (ESP). The ESP of Hamon are considered as

effective dust collectors with the collection efficiencies of up to 99% with

guaranteed outlet emissions as low as 20 mg/Nm3 with minimal pressure

loss.

Consortium partner RJM International is responsible for designing and

engineering the NOx reduction system, using its combustion modelling

capabilities to achieve the 75% reduction in NOx emissions mandated

by the EU. RJM’s equipment, such as new burner components, will be supplied to

the site by RJM International and installed by Engineering Dobersek.

The reconstruction of the power station will be carried out in two phases. The

works commenced on December 2, 2019. The commissioning of Unit B1 is planned for

the end of 2020 and Unit B2 by the end of 2021. The modernization works are an

important contribution to improving air quality, enhancing environmental

protection and the strengthening of the infrastructure of Kosovo.

With this contract, Engineering Dobersek once more confirms its competence in

the field of power station technologies in South East Europe.

BIOMASS

ANDRITZ to supply a further High-efficiency

PowerFluid Circulating Fluidized Bed Boiler with Biomass Firing in Japan

International technology

group ANDRITZ has received an order from a Joint Venture between

Toyo Engineering Corporation and Nippon Steel Engineering

Co., Ltd., Japan, to deliver a PowerFluid circulating fluidized bed

boiler with a flue gas cleaning system.

The boiler will be part of

a new biomass power plant to be built in Omaezaki in Shizuoka Prefecture, Honshu

Island, some 200 km southwest of Tokyo, Japan, for the Omaezakikou Biomass Power

Plant. Commercial operations are scheduled to begin in mid-2023.

The PowerFluid boiler to

be supplied by ANDRITZ features low emissions, high efficiency and availability,

as well as high fuel flexibility. It forms an essential part of a

high-efficiency biomass power plant for supply of green energy to the national

grid. The biomass power plant fired with wood pellets and palm kernel shells as

main fuels will generate around 75 MWel of power.

This is now the seventh

order in two and a half years for supply of an ANDRITZ PowerFluid circulating

fluidized bed boiler to the Japanese market. This confirms ANDRITZ’s

comprehensive expertise and acknowledged competence in the biomass-fired

fluidized bed boiler sector.

GAS TURBINES

MHPS Technology Upgrades at

Termocandelaria Improve Colombia’s Electric Sector Capacity, Reliability and

Efficiency

Mitsubishi Hitachi Power Systems

(MHPS) and Termocandelaria announced an order for a new MHPS steam

turbine and M501F4 gas turbine upgrades for the Cartagena power plant, along

with an exclusive 15-year Long Term Service Agreement (LTSA). The order will

enable the plant to operate on a combined cycle basis, increasing plant output

by more than 74 percent and improving fuel efficiency by more than 35% — from

10,219 to 6,618 BTU/kWh lower heating value (LHV). It meets Termocandelaria’s

goals to create electricity more affordably and reliably and with lower carbon

emissions.

As part of the service package and MHPS’s long-standing commitment to Latin

America, the company will upgrade the plant’s existing Westinghouse

gas turbines by applying Advanced Class Gas Turbine materials and coatings to

enhance performance, extend maintenance intervals, increase reliability and

lower life cycle maintenance costs.

The LTSA includes the MHPS-TOMONI™ suite of Total Plant Solutions, which uses

artificial intelligence monitoring tools to help guarantee the reliability and

availability of what will be the most efficient combined cycle plant in

Colombia. Marco Sanchez, MHPS Americas Vice President and Head of Intelligent

Solutions, said, “MHPS Total Plant Monitoring develops predictive modeling

scenarios to detect potential maintenance needs before they become issues and to

enable condition-based maintenance.”

The customized MHPS hardware and software solutions will increase plant capacity

from 324 to 566 MW, lower fuel and maintenance costs, and increase plant

flexibility to produce affordable power for the citizens of Cartagena.

Marcos Meireles, Rio Energy’s CEO, said “We are very excited to install the

first GE’s Cypress wind turbines in Brazil. This agreement

reinforces our commitment to help grow Brazil’s installed base, by investing not

only in adding new turbines, but also introducing a new technology to advance

onshore wind in Brazil.”

The contract also includes a ten-year operation and maintenance (O&M) agreement

for all equipment supplied by GE at the wind farm, with the potential to extend

to 20 years.

WASTE-TO-ENERGY

Commercial operations achieved at

Two New Wheelabrator Technologies Waste-to-Energy Facilities in U.K.

Wheelabrator Technologies

realized major milestones in the U.K. in 2019 when two new waste-to-energy

facilities reached full commercial operations.

After three years of construction, the creation of approximately 1,500 jobs and

$110K (£85K) in contributions to local community causes and initiatives, the

waste-to-energy facilities—Wheelabrator Parc Adfer, located at Deeside in North

Wales, and Ferrybridge Multifuel 2 (FM2) in West Yorkshire—commenced operations

in late December and will now play a critical role in the region's environmental

and energy infrastructure.

Combined, Wheelabrator Parc Adfer and FM2 will process up to 964,000 tons per

year (875,000 tonnes) of residual waste. Together, they will utilize waste as a

fuel to generate a total output of 98MW (gross)/89 MW (net), enough electricity

to power an estimated 210,000 U.K. homes and businesses.

The facilities will divert residual waste from landfill, prevent the need for

export of waste to continental Europe, reduce greenhouse gases, recycle metals

that would otherwise go to landfill and generate clean, renewable baseload

energy.

Wheelabrator entered the U.K. market in 2009 to target Private Finance

Initiatives (PFIs) and shortly after commenced its support for the startup of

Riverside Resource Recovery Facility in Belvedere, London, leveraging

Wheelabrator's operational excellence in the U.S. over the last 45 years.

Wheelabrator has since successfully developed, financed and managed the

construction of four waste-to-energy facilities. The first to be delivered was

Ferrybridge Mutlitfuel 1 (FM1), part of the Multifuel Energy Limited (MEL) joint

venture with SSE, which commenced commercial operations in July 2015 to process

744,000 tons per year (675,000 tonnes) and generate 79MW (gross)/72MW (net)

after being built by Hitachi Zozen Inova (HZI). It is now recognized as one of

the most efficient waste-to-energy facilities in the U.K. FM2, also built by

HZI, is expected to achieve comparable levels of performance, being managed by

the same management team within the MEL joint venture. Since commencing full

operations in December, Wheelabrator Parc Adfer, built by EPC contractor CNIM,

has performed exceptionally well with a capacity of 220,000 tons per year

(200,000 tonnes). Wheelabrator Kemsley, also being built by CNIM, is currently

progressing hot commissioning and is expected to come online in Q2 2020. The

facility will process 605,000 tons (550,000 tonnes) and generate 69MW

(gross)/63MW (net) when the facility is taken over from CNIM.

Once all four assets are operational, they will process 2.3M tons (2.1M tonnes)

of residual household and commercial waste, and generate 1.1M net MWh of

renewable, baseload energy each year.

Bob Boucher, President and CEO at Wheelabrator, said: "This is a significant

accomplishment for our business and is transformational for our team in the U.K.

as we commence operations at both Wheelabrator Parc Adfer, and FM2, the second

facility within our MEL joint venture with SSE. Growth in this market has been

our number one strategic priority and I am proud of our team and our customers

for continuing to demand and support sustainable waste management in the U.K.

Takeover of these two facilities is the result of many years of commitment, hard

work and strong partnerships with our customers and the communities we operate

within."

"There remains a significant capacity gap in this market, and we continue to

explore opportunities to develop new waste-to-energy facilities to ensure local,

sustainable waste management solutions, and provide energy security for the U.K.

With limited landfill space, high landfill taxes, high costs and increasing

barriers to exporting waste to continental Europe and the need to invest in

baseload electricity generation, Wheelabrator is well-positioned to unlock

future opportunities to provide sustainable waste management to local

communities."

Wheelabrator's active development pipeline is already well-advanced with a

further three U.K. projects, Wheelabrator Kemsley North in Kent, located next to

our almost complete Wheelabrator Kemsley facility, Wheelabrator Harewood in

Hampshire, and Skelton Grange in Yorkshire, which will be developed with SSE as

part of the MEL joint venture.

Boucher said: "We look forward to continuing to develop, deliver and realize the

potential of clean energy in the U.K."

NUCLEAR

GE Hitachi Nuclear Energy and TerraPower

announce Collaboration to Support Versatile Test Reactor Program

GE Hitachi Nuclear Energy

(GEH) and TerraPower have announced a collaboration to pursue a

Public Private Partnership to design and construct the Versatile Test Reactor

(VTR) for the U.S. Department of Energy (DOE).

The two companies recently submitted a joint response to an Expression of

Interest issued by the Battelle Energy Alliance (BEA) on behalf of

the DOE, which seeks stakeholders interested in forming a partnership for a cost

sharing arrangement to design and construct the VTR utilizing sodium fast

reactor technology.

"This collaboration brings together a strong team of engineers and scientists,

which has considerable experience in sodium reactor technology," said Jay

Wileman, President & CEO of GEH. "The combined team has complementary and unique

experience with the credibility to lead the VTR design, procurement and

construction effort. We are excited to work with TerraPower on such an important

project."

"To achieve nuclear energy’s full potential, business and government must work

together to invest in both testing new materials and demonstrating advanced

technologies,” said Chris Levesque, TerraPower CEO. “America’s nuclear workforce

is ready to build next generation nuclear technology to deliver affordable,

clean energy, and to reestablish American leadership in nuclear technology. The

VTR offers a domestic platform for innovation that promotes American economic

and national security.”

Energy Northwest,

a utility consortium with nuclear power plant operating experience, will support

the joint GEH-TerraPower effort. Additional companies and investors have

expressed interest in being part of this effort and, if brought on board, will

be named later.

The U.S. Department of Energy Office of Nuclear Energy established

the VTR program to introduce fast neutron spectrum technology that does not

currently exist in the U.S. and to support accelerated development of nuclear

fuels and materials for advanced reactors.

In November 2018, BEA selected GEH and its PRISM technology to support the VTR

program. Since then GEH has been actively engaged in development of the VTR

conceptual design. TerraPower has supported the VTR program by making

enhancements to the VTR’s design and has invested ten years of sodium technology

development into its traveling wave reactor.

SNC-Lavalin contracts to extend Life of

CANDU Reactor at Romanian Nuclear Plant

Candu

Energy

will work on upgrades to extend the operating life of a 24-year-old Romanian

nuclear power unit.

Candu, a member of the

SNC-Lavalin

Group,

was awarded a $10.8 million contract by

Societatea

Nationala Nuclearelectrica S.A.

(SNN) for engineering analysis and assessments on the Cernavoda Unit 1 CANDU

nuclear reactor. The contract is focused on the fuel channel and feeders

assemblies with the objective of extending the operating life of the plant by

approximately 4 years, up to 245,000 effective full power hours (EFPH) from the

original design life of 210,000 EFPH. The extensions would enable the Cernavoda

plant to operate safely until it is ready for refurbishment in 2026.

In October, SNN had also awarded SNC-Lavalin and its partner

Ansaldo

Nucleare

the condition assessment work which will determine the scope of repair and

replacement of other equipment as part of the Cernavoda Unit 1 refurbishment

outage.

“SNC-Lavalin looks forward to continuing our long relationship with SNN to

optimize the operation of Cernavoda Unit 1 in preparation for a refurbishment

that will contribute to over 60 years of CANDU reactor life,” said Sandy Taylor,

President, Nuclear, SNC-Lavalin. “Our dedicated project execution team has

exceptional expertise in this area, having completed similar assessments for

several CANDU clients around the world.”

Cernavoda Unit 1 produces over 700 MW of electricity, about 10 percent of

Romania’s electricity demands. It was commissioned and began commercial full

power operation in December 1996.

Nuclear power units do not emit carbon dioxide. Officials estimate that

Cernavoda Unit 1 has avoided the release of more than four million metric tonnes

of CO2 annually that would have been produced by a coal-fired plant,

according to the release.

CANDU, known as Canada Deuterium Uranium, was invented in Canada. It uses

deuterium oxide as a moderator and uranium as a fuel, according to the Canadian

Nuclear Association.

The CANDU reactor also has been used at the Bruce, Darlington and Pickering

power plants.

ACCESSING ALL THE PROJECTS AND INFORMATION ONLINE

This Utility E-Alert is part of the Utility Tracking System. The system allows

you to instantly retrieve project details, profiles of each coal-fired power

plant worldwide, the right contacts at the OEM and A/E firms and summaries of

all the scheduled FGD and SCR projects. You need a user name and password to

access this system. If you have forgotten your user name or password or are not

sure whether you are eligible to access this system, please send email to

editor@mcilvainecompany.com.

*** The Utility E-Alert is for the exclusive use of the registered subscriber to

whom it is electronically delivered. Unauthorized distribution is prohibited.

***

© 2020 McIlvaine Company