FGD

and DeNOx

NEWSLETTER

January 2007

No. 345

Review of Capital and O&M Costs for FGD Retrofits

Thomas Meehan and Peter Kelly of Sargent & Lundy reviewed capital and O&M costs for wet FGD systems. The typical wet FGD project was defined as a retrofit to a 500 MW unit requiring 98 percent SO2 removal from an inlet SO2 greater than 6 lb/MMBtu. FGD costs depend on design requirements, site specific issues, ancillary capital projects that may be required, labor cost and availability, construction schedules, changing material prices, retrofit complexity, lead times, etc.

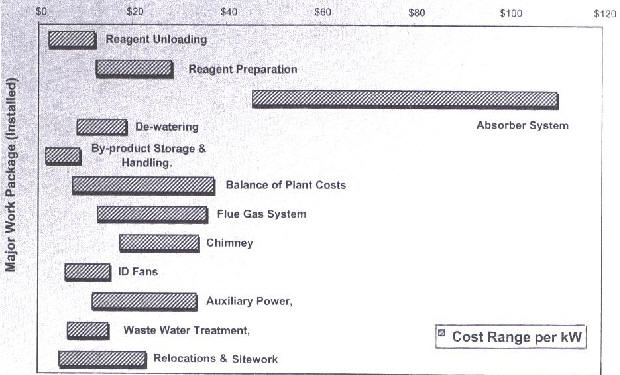

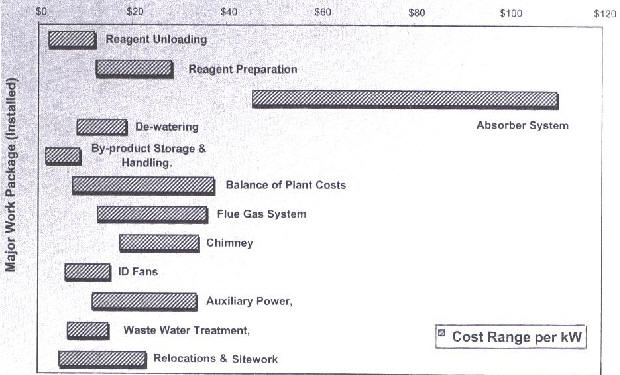

Figure 2 below shows capital cost ranges ($ per kW) for the various wet FGD system components including limestone system, absorber system, dewatering system, material handling (both limestone and byproduct), flue gas system (chimney, fans and ducts), auxiliary power, waste water treatment, balance-of plant, sitework and relocations. Total equipment, material and labor costs constitute 64 percent of the total projected costs (“wet FGD equipment and labor” account for 25 percent of the 64 percent and “other equipment and labor” make up the rest) with escalation, contingency and cost-of-funds 22 percent and indirects (owner’s cost, engineering support) 14 percent.

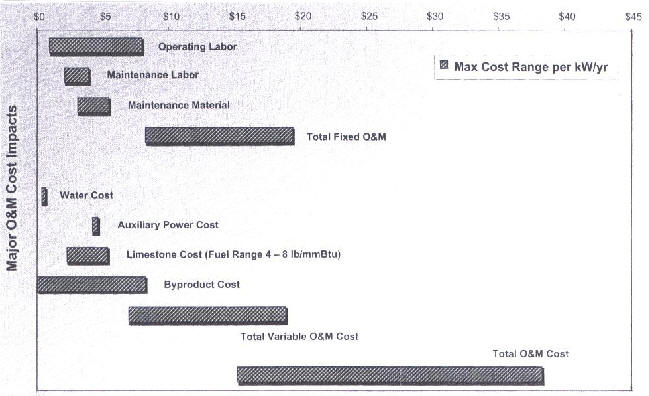

Figure 3 below shows cost ranges for O&M (operations and maintenance) costs for wet FGD systems ($ per kW per year). Percentage breakouts are byproduct landfill costs 23 percent, auxiliary power cost 19 percent, maintenance material 18 percent, limestone cost 15 percent, maintenance labor 13 percent, operating labor 9 percent and water cost 3 percent.

Back to FGD and DeNOx Newsletter No. 345 Table of Contents