Industrial Valve World Markets Update

October 2018

McIlvaine Company

TABLE OF CONTENTS

Creating a Winning Strategy for the Valve Market

Valves at WEFTEC

Media and Valves

Determining Competitor Market Shares and Strategy

Steel Industry Valve Purchases Will Exceed $1.7 billion this Year

____________________________________________________________

Creating a Winning Strategy for the Valve Market

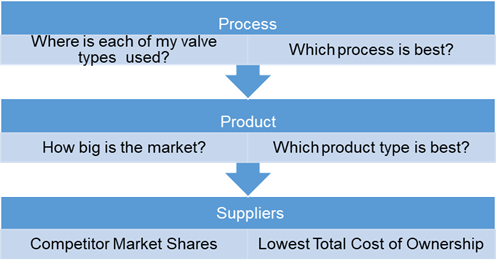

Suppliers and purchasers of valve products and services have the same basic

questions but with different perspectives. The purchaser must select a process,

the type of valve to use in that process, and then choose the best supplier.

Increasingly purchasers are conducting total cost of ownership (TCO)

evaluations. (1)

Supplier Questions

vs

End User Questions

The supplier of a high performance valve needs to understand the processes and

how his product will be used in those processes. He wants to know how big the

market is for this product. He wants to know if he has the lowest total cost of

ownership product and if so how does he create a winning strategy.

An important aspect is competitor analysis and determination of market

shares for the various players.

There are different strategies for high performance valves as opposed to general

performance valves. This analysis focuses on just high performance.

However high performance is defined as a valve which is purchased based

on lower total cost of ownership as opposed to just price and delivery. It is

therefore possible to move a general performance manual on/off valve into the

high performance category by adding automatic and smart features.

There are potential benefits to suppliers resulting from detailed forecasts of

the purchase opportunity for each product at each prospect.

This opportunity needs to be clarified with a strategy which is specific

to each one of the many prospects.

This opportunity is tied directly to Lowest Total Cost of Ownership Validation

(LTCOV). Determining the TCO for

the product is only the first step.

What is the TCO for each of the competitor products? What competitors

initiatives or innovations can impact the SWOT analysis?

Validation is more than just a

white paper which lays out the basis for the LTCO.

Validation includes convincing the customer

that the product is the best.

This entails coordination with publishers, conference organizers, and

associations.

There is now the opportunity to make market research and associated technical

analysis the foundation of business strategy rather than a peripheral tool.

Sales leads are used because the supplier does not understand the

customer needs. If the supplier has

detailed forecasts of the opportunity with each purchaser, understanding of the

purchaser needs, the products to best serve those needs, and the optimum program

with publishers, and conference organizers he will have a winning strategy.

Future as well as present market shares of competitors are needed.

The future share is in part based on product improvements.

It is also shaped by the sales activity.

One useful tool is analysis of

competitor advertising and exhibition expenditures by region and industry

as well as product. This indicates

the effort which the competitor is undertaking to capture market share or to

hold it. If this analysis is

continued over the years patterns emerge as to where competitors are increasing

expenditures to gain market share.

The suppliers and purchasers both seek to understand the TCO aspects of a

competitor product for a specific

application. Advertising in a

magazine focused on a specific industry is revealing.

Chemical Engineering has

multiple valve advertisements in each issue.

|

Chemical Engineering - September

2018 - Valve Advertising |

||

|

Company |

Pages |

Subject |

|

Emerson |

1 |

Engineering and project

management-automation |

|

Gemu |

0.5 |

Diaphragm valves |

|

Swagelok |

1 |

Small valves |

|

A-T Controls |

0.2 |

PFA lined ball valves |

|

Proco |

0.2 |

Check valve |

|

Auma |

0.5 |

Valve actuators |

|

Plastomatic |

0.5 |

Various designs in plastic |

In a recent issue A-T Controls advertised its PFA lined ball valves. This

company is one of 20 valve manufacturers who have products addressed to highly

corrosive, medium temperature, non-abrasive service.

This excludes the less expensive all plastic valves which are not suited

for the conditions. It excludes the valves which have to withstand abrasion and

require urethane or other abrasion resistant coatings.

This advertisement will be of interest to specific types of chemical

manufacturers. PFA lined valves are

well suited to chlorine service.

The tonnage of chlorine manufactured at each site around the world is

identifiable. The use of that

chlorine by others can also be

traced. Therefore the supplier can obtain useful forecasts for the opportunity

for PFA lined ball valves at thousands of suppliers and users of chlorine.

One of the uses of chlorine is in wastewater treatment plants.

These plants are users of multiple treatment chemicals.

The suppliers of valves for wastewater use are mostly identified in the

exhibitor directories of wastewater

exhibitions. The largest North

American wastewater exhibition is

WEFTEC with 20,000 visitors. Here

are the numbers of valve exhibitors by product type for the 2018 exhibition.

·

Valve Operators & Controls (32)

·

Valves: Air (19)

·

Valves: Automatic (25)

·

Valves: Backflow Prevention (23)

·

Valves: Check (34)

·

Valves: Control (30)

·

Valves: Gate (27)

·

Valves: Plug (16)

·

Valves: Rotary (11)

A dozen magazines had stands at the 2018

WEFTEC. They handed out

current issues with exhibitor coverage.

They also conducted email campaigns prior to the show featuring specific

exhibits. During the show several

conducted video interviews.

Publications, conferences and exhibitions are where revelations of new

developments can be communicated and where the LTCOV can be established.

This means inclusion of the most relevant material. Those suppliers who

are confident that they have the LTCO will have every reason to make it

financially attractive to the media to provide actionable analyses.

This show has been used as an analysis of the benefits of interconnection of

suppliers, media, and event organizers

Municipal Wastewater Services

Here are the details about the venue

WEFTEC 2018

91st Annual Technical Exhibition &

Conference

Conference: September 29 - October 3

Exhibition: October 1 - 3

Core Hours: 8:30 am - 5:00 pm daily

New Orleans Morial Convention Center

Valves at WEFTEC

Here are some highlights of the valve exhibits

Lift Station Valves furnished by DeZURIK to Phoenix

APCO SRA Surge Relief Angle Valves were installed on a new Lift Station in the

city of Phoenix. New freeway construction required the existing lift

station to be relocated. The new location is in a hilly part of town with

elevation changes, and the Lift Station discharges into a force main system. The

8” SRA-3000A Surge Relief Angle valves are designed to prevent line damage from

surges that occur when the lift station pumps cycle on and off. The surge valves

were installed and set to relieve system pressure at 135 psig. DeZURIK PEC

Eccentric Plug Valves are used as isolation valves on the lines.

The surge relief valve is typically installed downstream of the check or pump

control valves on the pump discharge header with the valve inlet connected to

the side outlet of a tee and the valve outlet piped to the sump. The normally

closed surge relief valve opens quickly when the system pressure rises above its

adjustable relief pressure setting allowing fluid to be discharged from the

system through the open surge relief valve to atmosphere. While the surge relief

valve is open, the system is no longer contained, fluid compression is limited

and surge pressure is controlled (green line). The valve will remain open as

long as the system pressure exceeds the valve’s relief pressure setting. The

valve will slowly begin to close at an adjustable rate as the surge pressure

subsides and the system pressure falls below the valve’s relief pressure

setting. DeZurik will be at stand

4929 at WEFTEC

Egger Booth

1543

Egger’s Iris valve provides Stable, Linear, Accurate, Repeatable and Reliable

control of aeration basins.

In the

past, WWTP’s have upgraded their processes with Fine bubble diffusors,

High-speed Turbo Blowers, Hyperboloid mixers but never dealt with the most

critical & final piece of the puzzle; a good process control system including s

unique valve design. The laminar flow characteristics can reduce blower energy

consumption 20% through better control.

Asahi/America Booth 1145

Asahi/America, Inc., a manufacturer and distributor of corrosion resistant

thermoplastic fluid flow solutions including valves, actuators and piping

systems, will be exhibiting in booth 1145 at WEFTEC. Asahi will be featuring two

of their newest solutions at the show, the latest innovation in butterfly

valves: the Type-57P; and the compact and powerful Series 17 electric actuator.

The Type-57P butterfly valve is the next generation of Type-57 butterfly valves.

The redesigned valve is available in an ANSI wafer-style connection and shares

the same face-to-face dimensions as all like-size Asahi/America Type-57

butterfly valves.

New Design Features

·

Molded tag holes for valve identification and

labeling

·

Redesigned indicator plate for lever handle

models 0° closed to 90° open legend with 10° intervals

·

Improved design of seat and disc bushing for

increased internal sealing performance

·

Newly designed disc and seat for added valve life

The Type-57P’s body and disc are injection molded for durability, and the 316

stainless steel stem is non-wetted. For high cycle life and smooth torque, the

seat and disc bushings have been fitted with dual O-ring seals.

Asahi/America’s Type-57P butterfly valve is available in sizes 1-1/2” through 8”

with a lever, and in 1-1/2” through 14” with our Plasgear™ operator. Available

body and disc materials include PVC, CPVC, PP and PVDF. The Type-57P top flange

features an ISO 5211 F07 – F14 bolt circle, and all sizes can be electrically or

pneumatically actuated.

Asahi/America’s Type-57P is assembled to customer specification and tested in

their Lawrence, MA facility.

In addition, Asahi will be featuring their new Series 17 actuator at WEFTEC.

The compact, lightweight and powerful Series 17 electric actuator features a

reversing motor with multi-voltage capabilities, an internal heater, auxiliary

switches, and two LED position indicators.

Internally, the Series 17 includes a permanently lubricated steel gear train and

declutchable manual override.

The Series 17 also features a combination NEMA 4X and 6 enclosure, which is

finished with a thermally bonded powder coat to protect against corrosion, an

ISO bolt circle and flying leads.

Media and Valves

A - Magazines and Interconnection of People and Knowledge

The Industrial Internet of Wisdom interconnects people and knowledge through

publications, conferences, and webinars. These provide the support information

for the decision systems and Lowest Total Cost of Ownership Validation (LTCOV).

Transfer of knowledge from one industry to another is also important. Municipal

and industrial wastewater innovations need to be shared. There also needs to be

interconnection between the systems designers and the suppliers of valves.

Various publishers exhibiting at WEFTEC make the interconnection between

industries e.g. industrial wastewater and municipal wastewater or between valves

and industries.

Valve suppliers gain insights on new technology such as nutrient recovery and

valve problems such as with struvite in these magazines exhibiting at WEFTEC

According to Valmatic Madison

Metropolitan Sewerage District is one of a number of utilities making the switch

to the installation of glass-lined plug valves to alleviate their Struvite

problem.

http://www.valmatic.com/pdfs/MissionPossible.pdf

One solution is the switch from motorized plug valves to motorized pinch

valves

http://www.onyxvalve.com/uploads/docs/Onyx_and_Struvite_Readers_Digest.pdf

|

Magazine |

Stand |

|

Chemical Engineering |

809 |

|

Chemical Processing |

542 |

|

Endeavor Business Media |

4051 |

|

Empowering Pumps |

4751 |

|

Environmental Science and

Engineering |

2246 |

|

Global

Water Intelligence |

6659 |

|

Modern Pumping Today |

5150 |

|

Pumps & Systems |

2852 |

|

Stormwater |

1652 |

|

WaterWorld |

3911 |

|

Water & Waste Digest |

4028 |

B - Endeavor Business Media

is offering industry and product interconnection. The Process Flow Network

covers innovative solutions for the process industries. Together, the three

brands that make up the network — Processing, Flow Control and Water

Technology — serve a diverse audience of engineers, corporate managers, plant

operators and other process industry professionals. You can learn more about the

Process Flow Network at WEFTEC Booth #4051.

C - Enviromental Science &

Engineering

has struvite data.

In November 2015, two HydroFLOW 160i units were installed on the sludge

pipe feeding the GEA Westfalia Separator model CB 505-00-32 centrifuge at

Somersworth N.H. One unit was placed before the centrifuge, just after the

thickened waste activated sludge pump, and the other was placed before the feed

tube just before the centrifuge. Both units were installed without process

down-time as they are fitted around existing piping and do not require plumbing

modifications.

The units use 120V AC and draw less than 1 Amp, which is similar to the power

consumed by a 60-watt light bulb.

Success for this facility meant reducing polymer usage and producing dryer cake,

while not adversely impacting the centrate quality. The centrate quality in

Somersworth typically averages about 500 mg TSS/L, but rarely exceeds 1,000 mg

TSS/L. Surpassing the 1,000 mg TSS/L threshold could affect the plant treatment

capacity.

https://esemag.com/wastewater/new-device-reduces-polymer-use-and-controls-struvite-during-sludge-dewatering/

D - Modern Pumping Today.

One of the recent feature articles covers struvite removal

https://modernpumpingtoday.com/removing-struvite-from-wastewater-systems/

The article above

on struvite removal at NYC with a special polymer was contrasted to an

approach which would have made centrifuge pond adjustments. This article

presents a third option.

A wastewater treatment company in Canada uses a number of

dewatering centrifuges to remove water from sewage sludge. After the sludge has

been removed the water is purified and then discharged. Purification occurs in

the sludge dewatering centrifuge where the centrifuge’s force separates the

sludge from the water.

Struvite formed inside the sludge dewatering centrifuge

necessitating the need for the centrifuge to be stopped and cleaned every 800

hours of operation (approximately two months) which took workmen a day to clear

with chemicals, hammers and chisels.

A Scalewatcher electronic descaling system was installed at the

centrifuge with an induction cable around the 6-inch supply mains. When, after

four months, the treated centrifuge was opened during the first inspection, it

appeared that the wall was only covered with a minimal deposit of softened

struvite. Two months later the centrifuge was opened and inspected again

whereupon it was found to be even cleaner. To confirm the results, the

Scalewatcher was switched off. Shortly afterwards, the operators noticed that

the deposits had returned. When the Scalewatcher was switched on again the

Struvite disappeared. The magazine covers municipal and other pumping

applications and includes in depth analyses which can aid decision making. Vince

Marino

vince@modernpumpingtoday.com

will be at the stand 5150

E -

WaterWorld Stand 3091 has an easily used search engine. Struvite

causes alve problems. So information on the incidence and solutions are

relevant. A search under struvite shows a 2018 article -

Howard County Department of Public Works engaged HDR to provide engineering

design services for upgrades to the biosolids facilities at the Little Patuxent

Water Reclamation Facility in Savage, Maryland. The Little Patuxent facility

used dewatered cake lime stabilization for biosolids treatment. The changes to

the biosolids processing included eliminating the lime system and replacing it

with anaerobic

digesters, centrate demmonification and associated solids

screening, thickening, odor control and digester gas handling improvements.

After an extensive evaluation of phosphorous removal

technologies, the design was based on Centrisys AirPrex because of its

demonstrated ability to prevent struvite precipitation in downstream processes,

including piping and the solids dewatering equipment. The Little Patuxent

facility uses decanter centrifuges for biosolids dewatering

https://www.waterworld.com/articles/2018/06/little-patuxent-water-reclamation-facility-upgrades-system-with-airprex-for-sludge-optimization-and.html

In a 2017 article in WaterWorld - CNP™

Technology Water and Biosolids Corp.

recently announced

AirPrex®,

a

sludge optimization and phosphorus

recovery process, has been selected

for the Liverpool Wastewater Treatment Plant (WWTP) by the Medina County

Sanitary Engineers in Ohio.

A comprehensive article on nutrient recovery in a 2016 issue is provided at

https://www.waterworld.com/articles/wwi/print/volume-31/issue-6/featured-articles/nutrient-recovery-2-0.html

This article is from the sister publication, Water & Wastewater International by

Dr. Christian Kabbe

from the Berlin Centre of Competence for Water, Germany.

For more information, email:

Christian.kabbe@kompetenz.wasser.de.

The struvite problem and the interest in nutrient recovery is world-wide.

The quest for the LTCO

should also be world wide

F - Water & Waste Digest

Stand 4028 has a search engine with multiple articles on struvite. Here

is one from 2017 -

Struvia prevents uncontrolled struvite precipitation during

wastewater treatment. This Veolia process uses a patented mixing system,

TurboMix, to produce and separate struvite crystals within a single reactor.

This compact, resource-efficient, low-energy process saves on operating costs by

reducing struvite-related maintenance and reducing the amount of coagulant used

for chemical P removal, all while producing a valuable granular end product

consisting of magnesium ammonium phosphate crystals that are rich in recycled

nutrients.

https://www.wwdmag.com/treatment/struvite-removal

G - Chemical Engineering

The September issue will be distributed at WEFTEC.

There is a special advertising section on water treatment but the feature

articles are on boiler feedwater treatment. Advertisements for some WEFTEC

exhibitors appear in the main section but there are advertorials for each in the

special water treatment section.

Each of these is the equivalent of 0.5 pages of advertising.

So for GEMU, Flottweg and about half of the listed advertisers there is

the bonus coverage.

|

Chemical Engineering September

2018 CFT Advertising |

||

|

Company |

Pages |

Subject |

|

Cleaver Brooks |

1 |

Boilers, water systems, controls |

|

Emerson |

1 |

Engineering and project

management-automation |

|

Endress +Hauser |

1 |

Flow meters, transmitters, pH |

|

Badger Meter |

1 |

Flow meters |

|

Flottweg |

0.5 |

Centrifuges |

|

Ross |

0.5 |

Mixers |

|

Load Controls |

0.5 |

Viscosity measurement |

|

Gemu |

0.5 |

Valves, water treatment |

|

Swagelok |

1 |

Valves |

|

NOV |

1 |

Progressing Cavity Pumps,

screens, mixers |

|

Krohne |

0.5 |

Level transmitters |

|

Ekato |

0.3 |

Mixing |

|

A-T controls |

0.2 |

PFA lined ball valves |

|

Material Transfer |

0.5 |

Bulk bag discharger |

|

Paul O. Abbe |

0.2 |

Mixing, size reduction |

|

Proco |

0.2 |

Check valve |

|

Seepex |

0.5 |

Pumps , metering system |

|

Bionomic |

0.5 |

Modular scrubbers |

|

Ametek |

0.3 |

Viscosity analyzer |

|

Finder Pompe |

0.3 |

Centrifugal and plunger pumps |

|

Myron L |

0.5 |

Liquid measurement |

|

Arkema |

0.5 |

Kynar |

This format of advertising in the main section and advertorials in the special

section could be used to provide lowest total cost of ownership validation.

|

# |

Magazines |

Suppliers/ Consultants |

Operators |

Struvite |

|

A |

Eleven companies |

|

|

|

|

B |

Endeavor |

|

|

|

|

C |

ES&E |

GEA |

Somersworth NH |

x |

|

D |

Modern Pumping Today |

Scalewatcher |

Plant in Canada |

x |

|

E |

WaterWorld |

HDR, Centrisys, Berlin Centre |

Howard Cty. M.D

Medina Cty, Ohio |

x |

|

F |

Water & Wastes Digest |

Veolia |

|

x |

|

G |

Chemical Engineering |

Many |

|

|

Determining Competitor Market Shares and Strategy

The Mcilvaine Company provides market share data for thousands of air, water and

energy companies. However clients are seeking even greater segmentation by

industry, region and specific product,.

One of the tools for this more extensive segmentation is activity at

exhibitions. The geographic distribution as well as industry focus can be

determined. The detailed analysis

of exhibition activity at WEFTEC is shown at

Municipal Wastewater Services.

There were many water related exhibits at Singapore International Water

Week. We have a 20 page analysis just of the pump companies with displays.

We have been analyzing exhibition activity every third year for IFAT in

Munich and were a participant in the Pump Summit last year.

We have also just completed an analysis of exhibitors of non woven filter media

at Filtration 2018. The focus is on

air filtration, gas turbine, and

dust collector media with a more minor focus on liquid filtration media.

Filtech held in Europe is more focused on filtration equipment rather

than media and has the largest display of filtration equipment of any show

around the world.

A number of power related shows are reported in our Utility E Alert including

smaller venues such as the VGB air pollution conference or the Indian FGD&DeNOx

conference last week. Power-gen

shows in several regions of the world

include substantial CFT space.

The OTC exhibition in Houston is one of the largest oil and gas

exhibitions with more than 100 CFT exhibitors. Interphex in NYC is has dozens of

displays by CFT pharmaceutical

suppliers. ACHEMA in Frankfurt

provides hundreds of displays of CFT products for the chemical industry every

third year

The Cleanroom Technology exhibition in the U.K and a number of smaller European

exhibitions such as Lounges provide displays of

valve products used in cleanrooms.

The industry focused shows such as Semicon West have a number of displays

by valve suppliers but the valve

percentage of total space is

low.

Advertising is also a good indicator of activity by product, industry and

location . We tabulate the number

of pages, the subject matter and the service in which we will be evaluating it

|

Valve Advertising in

Pharmaceutical Manufacturing

July - August 2018 |

|||

|

Company |

# of pages |

Subject |

Service |

|

Cashco |

1 |

Regulator, valves |

IIoT, Valve |

|

Valve Advertising in Processing

- October

2018 |

|||

|

Company |

# of pages |

Subject |

Service |

|

AT Controls |

1 |

Valves and Controls |

Valve |

|

Jefferson |

0.2 |

Valve |

Valve |

|

Everlasting Valve |

0.5 |

Valve |

Valve |

|

Cashco |

0.5 |

Regulator, Valve |

IIot, Valve |

|

Griffco |

0.5 |

Valve |

Valve |

|

Assured Automation |

0.2 |

Valve |

Valve |

|

Hydrocarbon Processing - September 2018 -

Advertising |

|||

|

Company |

Pages |

Subject |

Service |

|

Swagelok |

1.0 |

Pressure measurement system |

Valve, IIoT |

|

Chemical Engineering - September

2018 - CFT Advertising |

|||

|

Company |

Pages |

Subject |

Service |

|

Gemu |

0.5 |

Valves, Water Treatment |

Valves |

|

Swagelok |

1 |

Valves |

Valves |

|

A-T controls |

0.2 |

PFA Lined Ball Valves |

Valves |

|

Proco |

0.2 |

Check Valve |

Valves |

|

Arkema |

0.5 |

Kynar |

Valves |

|

Pipeline & Gas Journal

July 2018 Advertising |

||||

|

Company |

Pages |

Subject |

Service |

|

|

Quarter Turn Actuation (QTA) |

0.5 |

Valve Actuators |

Valve |

|

|

Rotork |

1.0 |

Actuators |

Valve |

|

|

Wolseley |

1.0 |

Valve Automation |

Valve |

|

|

PTQ

Q3 (Jul, Aug, Sept) 2018

Advertising |

||||

|

Company |

Pages |

Subject |

Service |

|

|

Metso |

1.0 |

Valves |

Valves |

|

|

OHL Valves |

0.5 |

Valves |

Valves |

|

|

Zwick |

1.0 |

Valves |

Valves |

|

|

|

||||

|

|

||||

|

|

||||

Some of the advertisements are general and reference a number of products.

Swagelok has a full page on a pressure management system advertisement.

By contrast the A-T advertisement in

Chemical Engineering is just a

quarter page on just one type of lining for one type of valve.

The advertising and exhibition activity can be a function of initiatives to gain

market share rather than just keep it.

Therefore tracking this activity over time is useful.

For example one chemical company had the largest stand at WEFTEC a few

years ago and did not have a stand this year.

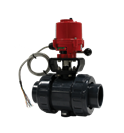

Steel Industry Valve Purchases Will Exceed $1.7 billion this Year

The world steel industry will spend over $1.7 billion this year for valves,

parts, and service. Many of the valve decisions will be made from the

headquarters of large international operators. This will necessitate a new

marketing approach by valve suppliers.

In the case of ArcelorMittal, the majority ownership is by an Indian individual

but the decisions regarding valve purchases may be made in Luxembourg which is

the company headquarters. ArcelorMittal is a major valve purchaser. Its valve

purchases for steel and mining applications are just under $100 million per year

of which $84 million is for steel applications.

As the world’s largest steel manufacturer, ArcelorMittal makes almost as much

steel as India itself. Yet India must more than double steel output by 2030 if

its smart cities, bullet trains, advanced manufacturing and safer housing are to

become reality. ArcelorMittal, with its partners Nippon Steel and Sumitomo Metal

is presently bidding to buy Essar Steel which is a large bankrupt Indian Steel

company.

Lakshmi Niwas Mittal owns controlling shares in Arcelor Mittal which he founded.

He is one of the world’s wealthiest individuals and sits on the board of Goldman

Sachs. He grew up in an Indian family in the steel business. Until the 1990s,

the family's main assets in India were a cold-rolling mill for sheet steels in Nagpur and

an alloy steels plant near Pune.

Lakshmi Mittal decided to strike out on his own and opened his first steel

factory PT Ispat Indo in Sidoarjo, East Java, Indonesia in 1976.

He then founded ArcelorMittal which is now the world’s leading steel and mining

company, with annual achievable production capacity of approximately 113 million

tonnes of crude steel, driven by 197,108 employees working in 60 countries.

ArcelorMittal is the largest producer of steel in North and South America and

Africa, a significant steel producer in the CIS region, and has a growing

presence in Asia, including investments in China and India. It is also the

largest steel producer in the EU, with significant operations in

France, Germany, Belgium, Spain, Luxembourg, Poland, the Czech Republic and

Romania.

It is also a mining leader. ArcelorMittal has a global portfolio of 14 operating

units with mines in operation and development and is one of the largest iron ore

producers in the world.

ArcelorMittal works with more than 70,000 direct suppliers, covering an annual

spend of around $50 billion for raw materials, energy, industrial products and

spares, as well as various services.

It manages a complex supply chain, using the principles of total cost of

ownership. If it purchases Essar Steel it is likely that major valve decisions

will be made in Luxembourg or in one of nine shared services centers the company

operates worldwide.

With remote monitoring of valve operations and data analytics the company will

have the background data to determine the lowest total cost of ownership. It has

invested heavily in IIoT working with ABB, Schneider Electric, GE, Siemens and

others. At the Olaberria plant in Spain, as an example, valves associated with

the melting, dust collection and other equipment are continuously monitored and

data analyzed.

Valve suppliers looking to increase sales in India as well as in other countries

will want to consider the following:

·

Purchasing decisions are going to be made by relatively few individuals who are

not likely to be at the plant site

·

Decisions are going to be increasingly made based on lowest total cost of

ownership

·

The successful valve supplier will need to prepare a lowest Total Cost of

Ownership Validation (LTCOV) for each application in each industry and then

LTCOVs for each major customer

·

We are entering the post digital era where the Industrial Internet of Wisdom (IIoW)

is empowering IIoT and will necessitate new marketing strategy for valve

suppliers.

·

This new era will make it possible for international valve suppliers to better

compete for valves to be used in India

The McIlvaine

N028

Industrial Valves: World Market

provides 50,000 forecasts of valves by type, end use location, and industry. It

also includes forecasts for the 200 largest customers

A program including forecasts for thousands of prospects is also available.

Details are provided at

www.mcilvainecompany.com

Bob McIlvaine can answer your questions at

rmcilvaine@mcilvainecompany.com

847 784 0012 ext.