Insitu Rare Earth Recovery System

The solution for maximizing flyash value,

improving the environment, and achieving

national security relative to rare earth supply

could be a system which labeled the Insitu Rare

Earth Recovery System.

Overview

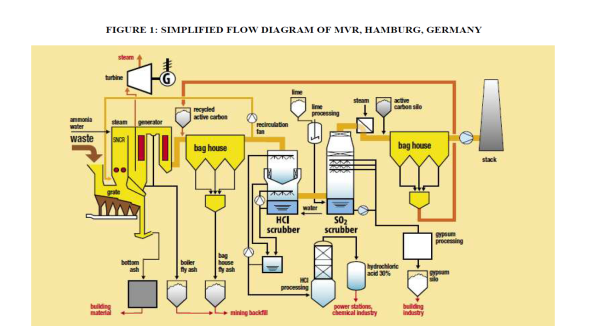

A number of power plants and many waste to

energy plants use two stage scrubbing systems.

Waste to energy plants in Europe sell by

product hydrochloric acid, gypsum, and valuable

metals while producing a contaminant free ash.

A number of 250 MW two stage scrubber systems

operated by Philadelphia Electric produced

magnesium sulfite for further processing to

sulfur products. These scrubber systems operated

from 1980 to 2012.

High efficiency particulate first stage

rod deck scrubbers captured the particulate and

HCl.

The second stage rod deck scrubbers

captured the SO2 using MgO.

The first stage operated at close to pH 6 but

could have operated in the manner of the

European waste to energy plants. They

recirculate water which quickly captures the HCl

and operates at pH 1.

The 30

percent hydrochloric acid slip stream maintains

the equilibrium.

Ion exchange resins are used following

the initial solids separation to capture the

metals. The acid and metals are then sold.

This process could turn out to be a very

important step forward for the world wide coal

industry.

But let’s just focus on the implications

for CCR compliance for coal fired boilers in the

USA. A

specific example would be A.B Brown 1 &

2.

A permit for a gas plant was denied so Vectren

is considering replacing its double alkali

scrubbers with one oxidation scrubber. At the

same time it is talking to suppliers about

beneficiating flyash as part of its CCR

compliance.

Instead of the oxidation scrubbers and upgrade

of the precipitators which are far beyond their

useful life the system could be replaced by the

two stage scrubbing process.

The plant could buy lower cost higher chlorine

coals and produce the rare earth’s feed stock,

hydrochloric acid and gypsum or ammonium

sulfate. It would produce flyash which is free

from metal and other toxic contaminants.

The tried and true scheme used in many Chinese

and some U.S. power plants is a final wet

precipitator. This can be installed in the top

of the second absorber or can be stand alone.

An alternative instead of the second

absorber would be a dry scrubber system.

Beneficiation of ponded sludge could be

accomplished by adding it as a reburn product

(similar to the WE Energies Prairie Station) to

the boilers.

The concentrated rare earths and other metals

could then be shipped elsewhere for further

processing.

Costs:

One of the biggest costs encountered by

those who are mining flyash landfills is the

size reduction of the flyash. In the proposed

system the flyash is at its original size from

sub-micron to plus 100 microns. So a major cost

is eliminated. There is no cost to acquire

hydrochloric acid

or to build a mixing system. It can

therefore be speculated that if the University

of Kentucky and Chinese government

determinations that extracting rare earths from

coal is economical then this scheme is much more

so.

What about the cost of the two stage scrubber?

One of the reasons that some power plants have

opted for two stage scrubbing in the past was to

capture the HCl before it gets mixed with the

gypsum. One small pre scrubber is all that is

needed for the HCl and particulate capture.

This means the second scrubber can be

316L instead of a more expensive alloy. There

are no chlorides to be washed from the gypsum

and no worries about FGD wastewater

contamination.

Bob McIlvaine was President of Environeering in

1969 when the company was contracted by United

Engineers to furnish the two rod deck scrubbers

for multiple units at Philadelphia Electric.

Environeering was the partner to Combustion

Engineering and furnished the marble bed

scrubbers for the world’s first commercial

limestone FGD scrubber at Union Electric

Merrimac. The rod deck scrubber was an

improvement which provided efficient absorption

but also varying particulate removal efficiency

depending

on the velocity and turbulence created

thru the rod decks.

Most of the first FGD scrubbers replaced

precipitators and removed particulate down to

0.1 lbs/ mmbtu. This was better than needed or

that was being achieved in most precipitators.

When the limits were reduced to 0.05 lbs it

required as

much as 20” w.g.

scrubber pressure drop to meet the

limits without a

precipitator.

Environeering furnished rod deck scrubbers to

Northern States Power for pre scrubbing on ten

units.

When the limits were reduced to 0.03 lbs

it became advisable to keep the precipitators in

operation.

Environeering prior to acquisition by

what is now Babcock Power installed

hundreds of rod deck scrubbers in many

different industries.

The concept was so successful that other

scrubber suppliers developed similar products.

The ability of the rod deck scrubber to remove a

varying amount of particulate depending on the

pressure drop combined with ease of utilizing

multiple decks, each with a different pressure

drop opens the door for classification of flyash.

If the rare earth processing would

benefit from such as classification it can be

done insitu at low cost.

McIlvaine Mini Scrubber

Particle separation in a scrubbing stage is a

function of the pressure drop which in turn is a

function of velocity, turbulence and to a lesser

extent the liquid flow. Many organizations have

had venturi scrubber pilot plants. These

plants can be placed at a plant and a slip

stream can be processed. This is the only way to

predict particle separation. Testing devices

such as cascade impactors are almost useless due

to the variations in shape and specific gravity

of particles.

McIlvaine took the concept one step further and

reduced the orifice scrubber to just 1 CFM so it

could be used in standard sampling trains.

Dupont, AERE Harwell, AirPol, Nalco, Martin

Marietta and other organizations have

successfully used this device to predict

scrubber performance. It was given the

commercial name of the McIlvaine Mini Scrubber.

McIlvaine offered the drawings and concept free

of charge to the Institute of Clean Air

Companies. Several members began using the

device but the organization never banded

together to make it a standard bid tool.

This device can be used by researchers to

determine the benefits of a multi stage scrubber

to separate flyash particles into appropriate

fractions for leaching. The multi stage scrubber

could capture the particles emitted from the

boiler in several fractions.

System Details

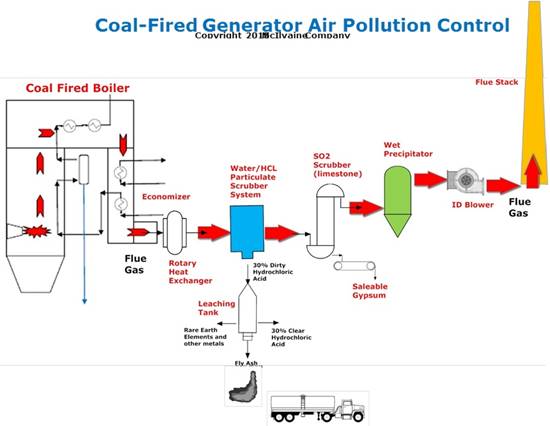

The flyash and HCl is captured in the rod deck

scrubber which operates at pH 1. A bleed stream

of 30 percent acid with the particulate is then

sent for further processing.

.

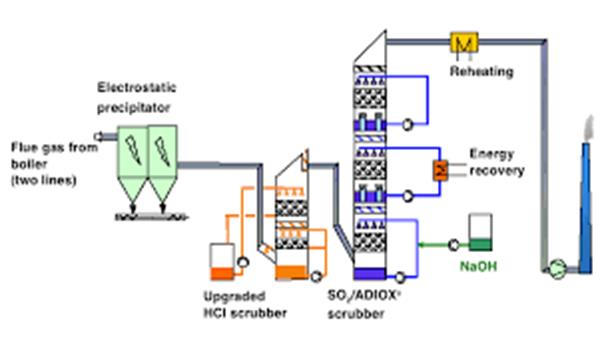

This schematic provides the mixing of HCl and

flyash in a system which eliminates the first

stage precipitator. It is therefore

attractive for old coal-fired power plants in

the U.S. as well as for new coal-fired power

plants in China. It does incorporate a wet

precipitator. Coincidently, this is common

in China

for other reasons (to meet tough new particulate

standards).

The HCl content does not have to be high. The

first stage scrubber starts with water and then

reaches equilibrium with 30 percent dirty acid.

A portion is bled to maintain this percentage.

The advantages of using high chlorine coals

would be that these coals are less expensive and

the byproduct sales volume of acid will be

higher.

The Chinese believe coal flyash is already a

very attractive source for REEs and are pursuing

it aggressively. One reason is that the CO2 emissions

are 75 percent less than from extraction through

mining. With the insitu option the energy

is much less than the processing of flyash from

ponds and therefore compares even more favorably

to energy required for mining ores.

European Waste to Energy Plants

Horsholm Denmark has a waste to energy system

with metals recovery and acid sale. At the end

of the incineration process, the extracted

acids, heavy metals and gypsum are sold for use

in manufacturing or construction. Small amounts

of highly concentrated toxic substances, forming

a paste, are shipped to one of two warehouses

for highly hazardous materials, in the Norwegian

fjords and in a used salt mine in Germany.

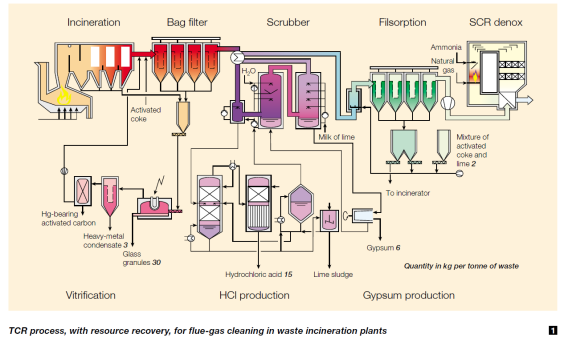

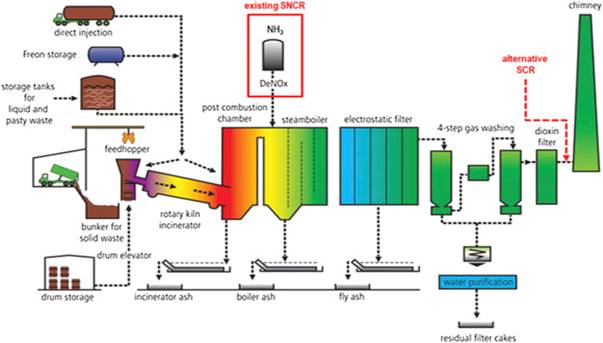

Other Multiple Scrubber Variations

TCR Process

Four

Step Scrubbing Process

Energy Recovery Variation