PUMPS WORLD MARKET

UPDATE

October, 2018

McIlvaine Company

TABLE OF CONTENTS

2019 Chemical Industry Pump Purchases

McIlvaine Market Forecasting and Analysis for Pumps demonstrated with WEFTEC

Analysis

Pumps at WEFTEC

Media and Pumps at WEFTEC

Determining Competitor Market Shares and Strategy

_________________________________________________________________

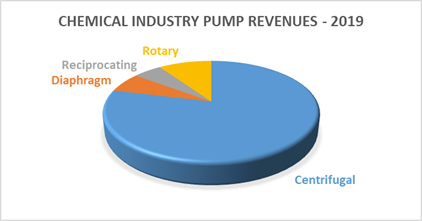

2019 Chemical Industry Pump Purchases

Chemical Industry purchases of

pumps including parts and services

will exceed $3.8 billion next

year. The centrifugal pump

purchases will exceed $2.8 billion. (1)

The market can be further segmented by pumps for new greenfield plants, new

replacement pumps for existing plants, parts, and service. The new greenfield

segment is less than 15 percent of the total.

This means that existing pump owners will make most of the purchasing

decisions. Furthermore these

existing plants are centralizing their purchasing.

BASF is specifying pumps for all plants from its headquarters in

Ludwigshafen. The company has

process management software and can track pump performance around the world.

Consequently relatively few people with a great deal of analytical

information are making more and more of the pump decisions.

These highly informed people are looking to interact with supplier personnel who

can add insights. Therefore

suppliers will need direct sales programs to target these influential people.

It is possible to determine the annual purchases of thousands of pump

customers in order to provide the foundation of a sales program. Nearly 1000

chemical companies spend more than $500,000 per year on pumps. More than 20

companies spend more than $35 million/yr.

|

Largest Pump Purchasers in the

Chemical Industry - 2019 |

||

|

Company |

Corporate Location |

World Pump Purchases |

|

Braskem |

Brazil |

|

|

Sinopec |

China |

xx |

|

Air Liquide |

France |

|

|

BASF |

Germany |

xx |

|

Linde |

Germany |

|

|

Evonik |

Germany |

|

|

Covestro |

Germany |

|

|

Mitsubishi Chemical |

Japan |

x |

|

Toray Industries |

Japan |

|

|

LyondellBasell |

Netherlands |

x |

|

AkzoNobel |

Netherlands |

|

|

Yara |

Norway |

|

|

SABIC |

Saudi Arabia |

x |

|

LG Chem |

South Korea |

|

|

Ineos |

Switzerland |

x |

|

Formosa Plastics |

Taiwan |

x |

|

Dow Chemical |

U.S. |

xx |

|

ExxonMobil |

U.S. |

x |

|

DuPont |

U.S. |

x |

|

PPG Industries |

U.S. |

|

|

All companies will spend more

than $35 million for pumps.

Those with x will spend more

than $50 million and

those with xx will spend more

than $100 million |

||

The investment in pumps at each plant is a function of the tons of chemicals

produced. Data is available on the production of each chemical at each plant.

There is also data on the type of production process used. For example there are

several different processes for making chlorine.

|

Installed Chlorine Production Capacities (kt

chlorine/yr) |

|||||||

|

Country |

Company |

Site |

Total |

Hg |

D |

M |

Others |

|

Austria |

Donau Chemie |

Brückl |

74 |

|

|

74 |

|

|

Belgium |

INOVYN |

Antwerp |

460 |

110 |

|

350 |

|

|

Belgium |

INOVYN |

Jemeppe |

174 |

|

|

174 |

|

|

Belgium |

Vynova |

Tessenderlo |

475 |

205 |

|

270 |

|

With this data the process pump investment can be determined. However, a company

such as Wacker Chemie makes chlorine on site and then uses the chlorine multiple

times in downstream processing.

This increases the pump purchases accordingly.

The pump purchases for water intake, cooling, wastewater, chemical

metering, and power plant ultrapure water can also be determined from available

data. Thanks to the regulatory

authorities the size of any wastewater discharge is known. The size of the

plants power generators are also known.

This is the basis for calculating

the ultrapure water and cooling water pump purchases. This includes

metering pumps as well as process pumps.

There is the opportunity to offer edge computer software which will be part of

the pump package and increase pump supplier revenue. (2)

Revenue can be further expanded by offering 24/7 remote monitoring.

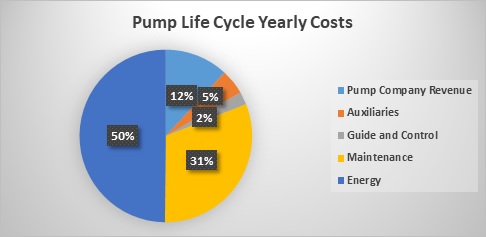

Presently pump suppliers capture just a small portion of the total

market.

The 50 percent spent on pump energy can be reduced with process management

programs. Maintenance can be reduced with 24/7 remote monitoring.

Since the original pump price is only 12 percent of the total annual cost, it is

important for pump suppliers to validate that their offering has the lowest

total cost of ownership.

The determination of the purchase opportunity for each major customer is the

foundation of a sales program. The Lowest Total Cost of Ownership Validation

(LTCOV) is the vehicle to persuade these major customers as to where to spend

their money.

McIlvaine Market Forecasting and Analysis for Pumps demonstrated with WEFTEC

Analysis

WEFTEC, being held in New Orleans, September 29 - Oct 3 is one of the largest

municipal wastewater conferences and exhibitions in the world. There will be 50

pump companies among the exhibitors. There will also be a number of good

papers which will address pump issues.

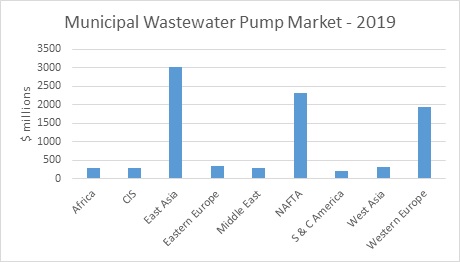

NAFTA is the second largest municipal wastewater pump market behind Asia.

A pre-show analysis of WEFTEC helps provide more insights on the Serviceable

Obtainable Market (SOM) and Wisdom based Obtainable Market (WOM). The SOM would

be a segment of the $9 billion Total Available Market (TAM) market. On the other

hand the WOM market can be even bigger than the TAM. The WEFTEC pre-show

analysis covers many of the parameters which will impact total cost of ownership

(TCO). The SOM is the market where the supplier can validate lowest total

cost of ownership (LTCOV). Therefore analysis of the information made

available at WEFTEC is important.

One of the problems being addressed at WEFTEC is struvite removal. It is a

relatively new problem caused in part by regulations which now require

phosphorous removal. Understanding of the phosphorous developments is important

to determining both TAM and SOM. The additional revenue from side stream

phosphorous removal increases TAM. The fact that struvite problems dictate

the use of one pump type over another affects SOM.

The SOM is also impacted by new developments by pump competitors. WEFTEC

provides a unique opportunity to learn about these developments.

Many of the pump exhibitors are displaying “smart” pumps which incorporate a

range of controls including edge process management systems. This

addition generates not only additional revenues at the time of original sale but

a recurring service income including remote continuous monitoring.

Pumps at WEFTEC

WEFTEC was bigger and better than

ever this year and even exceeded the record attendance in Chicago last year.

This show has been used as an analysis of the benefits of interconnection of

suppliers, media, and event organizers

Municipal Wastewater Services

Here are the details about the venue

WEFTEC 2018

91st Annual Technical Exhibition &

Conference

Conference: September 29 - October 3

Exhibition: October 1 - 3

Core Hours: 8:30 am - 5:00 pm daily

New Orleans Morial Convention Center

There

were a number of pump exhibitors. Here are some highlights

A - Idex-VanLare installs Pulsafeeder Metering Pumps

Located on the southern shore of Lake Ontario, the Frank E. VanLare Wastewater

Treatment Facility, Monroe County, N.Y., has a total treatment capacity of 660

mgd and is currently running around 100 mgd. The plant uses Non-metallic Eclipse

pumps to pump 12.5% Sodium Hypochlorite, Chlorine, for disinfection before the

final discharge of the wastewater. VanLare runs 24 hours a day, 365 days per

year.

VanLare originally installed peristaltic pumps for Sodium Hypochlorite and its

Environmental Service team was in search of a better solution. Peristaltic hose

life is unpredictable and inconsistent. These pumps are not leak free so worker

safety was also a concern because of inhalation and skin contact with the

chemicals. To solve the problem

they installed Non-metallic Eclipse pumps. Eclipse sealless design ensures zero

emissions of hazardous or regulated chemicals. These pumps have superior

chemical resistance. Service is quick and piping and electrical stay in place

because of the front pull-out design.

In addition to pumping Sodium Hypochlorite, VanLare installed three Non-metallic

Eclipse E25 pumps into the Ferric Chloride station. Ferric Chloride is used for

phosphorus removal. Pulsafeeder

will be a stop in the Sludge Dewatering

WEFTEC GDPS at stand 4308.

B - Accudyne will be a stop in the

Sludge Dewatering WEFTEC GDPS

Accudyne Industries business units manufacture pumps designed to inject

coagulants, disinfectants, softening agents, acids and bases for pH control and

de-chlorination chemicals into a plant’s water systems:

Milton

Roy metering pumps are efficient, cost-effective and reliably designed

specifically for wastewater treatment.

Milton

Roy mixers are widely utilized for basic treatments, sludge digestion and O2

injection.

Williams pneumatic metering pumps are ideally suited to precisely inject a wide

variety of chemicals designed for treating industrial water and wastewater.

LMI

chemical metering pumps are used for versatile applications in water and

wastewater treatment.

Sunflo high pressure centrifugal pumps are widely utilized for boiler feed water

and membrane filtration wash down.

The Milton Roy stand at WEFTEC will be 3739

C - Thames Water Modgen Plant switches

to SEEPEX Pumps

Originally built in the 1930s, the Mogden sewage treatment plant has undergone

major expansions over the decades to keep up with exploding population growth.

Operator Thames Water has now converted the large plant over to using SEEPEX

pumps. The customer needed more than just equipment, requesting a sophisticated

service package as well to ensure optimal operation.

This was no small challenge given the variety of sludges involved of differing

densities and temperatures. SEEPEX had to precisely design every pump – ranging

from the small metering pump for liquid polymers to the many transfer pumps for

sludge treatment – for specific requirements. Pumps also had to be developed

which were capable of moving 180 cubic meters of slurry to the sludge treatment

facility 16 km away. Additionally, special measures were required to ensure

smooth and efficient pump operation, reducing downtime and costs.

SEEPEX N300-36 transfer pumps were deployed, becoming milestones in

technological development by being the biggest progressive cavity pumps in

existence at that time in both length and weight.

Since commissioning, SEEPEX has performed full-service monthly inspection and

maintenance of the pumps, checking dry running, overpressure, wear, driving

power and efficiency. The key is performing preventive maintenance, on site and

the same day if necessary, before any breakdowns can occur.

The success is evident, as pump downtimes at the

sewage plant have been drastically reduced. SEEPEX UK is now responsible for

maintaining a total of 68 progressive cavity pumps and macerators at Thames

Water facilities and at the neighboring Iver South sewage treatment plant

located in Slough.

Seepex is

one of the identified stops in the

Sludge Dewatering WEFTEC GDPS at

stand 6939.

E - NOV Progressing Cavity Pump

The article below appears in the preview of WEFTEC in Industrial Water World,

the sister publication of WaterWorld. The magazines provide an important

function by educating potential visitors.

The EZstrip™ maintain-in-place progressing cavity pump from NOV is designed with

new features to make maintenance more user friendly. It has quick and safe

removal of the full drive train including rotor, stator, shaft, rod and seal.

With its patented Positive Torque Split Coupling Rod, maintenance and assembly

times are reduced. The tie-bar-free design allows the EZstator clamps to lock

the stator securely in place, further reducing stator removal time by over 50%

and improving safety of common maintenance operations. Available in cast iron or

stainless steel with a choice of rotor and stator materials, it suits multiple

applications.

National Oilwell Varco (NOV)

www.nov.com

Booth 1313

F - Netzsch

Booth 1319

On display will be the N.Mac Twin Shaft Grinder; FSIP (full service-in-place)

version of the industry-leading NEMO progressing cavity pump, including the new

xLC unit; the revolutionary TORNADO T2 rotary lobe pump, and the iFD-Stator 2.0.

Also to be highlighted is the maintenance-friendly FSIP NEMO progressing cavity

pump and its new xLC unit. Providing full access to all of the pump’s rotating

parts, the FSIP pump allows users to conveniently open the pump cavity on-site

and dismantle all rotating parts and simply install them again without having to

remove the pump or disconnect the piping. This significantly reduces

installation complexity and maintenance time. The new addition to the NEMO’s

portfolio, the xLC unit, triples the service life of the pump, particularly when

conveying difficult, abrasive media.

When wear occurs in the rotor-stator system, the new xLC unit allows the

performance of the pump to be re-established by adjusting the preload between

the conveyor elements

https://www.wateronline.com/doc/netzsch-to-showcase-range-of-innovative-pump-technology-weftec-0001

At the town of St Marys in Canada changes resulted in increasing the viscosity

of the thickened biosolids significantly, and also increased the percentage of

solids from 3% to a range of 8% to 14%. The centrifugal type pump previously

used, could not handle the highly viscous biosolids. The

Netzsch P.C replacement solved the problem

The N.Mac™ Twin Shaft Grinder from NETZSCH is designed to fragment a variety of

materials and is ideal for wastewater treatment and industrial applications.

Available in both channel and inline (flanged) housing construction, the N.Mac

can be installed into effluent channels or upstream from a pump. The cartridge

design features a leak-free combination of mechanical seal and bearing

cartridges, enabling quick and simple replacement and servicing.

https://www.waterworld.com/articles/print/volume-33/issue-10/products/products-services-wastewater-treatment.html

G - KSB: Pumps and Mixers will

be on display at booth # 4641

and will feature

Virtual experience of the new generation Amarex KRT submersible pump with the

F-Max impeller

•New generation Sewatec horizontal dry well pump with F-Max impeller

•New Additions to our hydraulic lineup (K-Max and E-Max)

•Most reliable submersible motor pump with axial propeller

•Complete line of our efficient vertical tubular casing pumps for your water

applications

•KSB System Analysis – System Efficiency Services

•Watch the Operations Challenge teams practice with the NEW KSB Maintenance

Event

In a 2018 WaterWorld interview KSB explains its "Cycle of Solutions" concept,

addressing how integrated technology is now needed for water intake to disposal

https://waterworld.brightcovegallery.com/detail/video/3580038825001/ksb

KSB now (as of 2012) offers the Sewatec dry-installed volute casing pump. Used

for wastewater transport and treatment, sludge handling, and stormwater

applications, the pump features a flexible hydraulic design to meet a multitude

of conditions. The Sewatec dry pump line is a derivative of the KRT line of

submersible pumps (also available from KSB). Because Sewatec's impellers,

bearings, mechanical seals, O-rings and discharge covers are interchangeable

with the KRT line, inventory streamlining is easy for customers that also use

KRT wet well pumps.

https://www.waterworld.com/articles/iww/print/products/2012/07/wastewater-pump-ksb-inc.html

H - BJM Pumps

Booth

1901

BJM Pumps® provides fluid handling solutions for industrial and municipal

services. BJM Pumps has grown quickly by supplying world class pumps and

accessories, priced competitively, through its global network of stocking

distributors in the United States, Canada and South America.

BJM Pumps has announced the new

XP-KZN heavy-duty, submersible, explosion-proof pumps that are designed for

tough conditions where explosion-proof, FM, C/US approval is needed. The XP-KZN

features a top discharge, slim-line design with an agitator to suspend heavy

slurries containing abrasive materials, as well as to allow for an easy fit into

tight, thin spaces. It features robust construction and unmatched design, making

it able to outperform and outlast standard wastewater predecessors in harsh

environments. The agitator helps keep solids suspended in liquid and helps

prevent the pump from clogging, reducing capital and operating costs.

https://www.waterworld.com/articles/print/products/2015/march/submersible-pumps.html

I - Boerger, LLC

Booth

5927

Headquartered in Germany with subsidiaries around the world, Börger develops,

manufactures and sells rotary lobe pumps, macerating technology and feeding

technology for the conveyance of low to high viscous and abrasive materials.

Börger’s core product, the Blueline Rotary Lobe Pump, is a self-priming,

valveless, positive displacement pump available in 21 models within six series

delivering flow rates up to 7,500 gpm. All Börger equipment is constructed using

MIP (Maintenance in Place) deisgn. This allows for an almost limitless

operational lifetime. Through the Quick-Release Cover all wetted parts can be

maintained or replaced without the removal of pipe or drive systems.

Rotary lobe pump interview with McIlvaine at WEFTEC 2010

http://www.mcilvainecompany.com/WEFTEC_2008/WEFTEC2008BorgerRotaryLobePumps.htm

J - Flygt,

A Xylem Brand

Booth

5939

Xylem's Flygt manufacturers submersible pumps, mixers and mechanical aeration

equipment for use in markets ranging from water and wastewater treatment, raw

water supply, abrasive or contaminated industrial processes, mining and

irrigation.

Operators of a

municipal wastewater pumping station in the rural town of Lomma on Sweden’s

south-western coast agreed to install and trial a revolutionary new wastewater

pumping system in an effort to solve clogging issues at the pump station.

As well as delivering clog-free pumping, Xylem’s Flygt Concertor, a

state-of-the-art pumping system with integrated intelligence, significantly

reduced energy consumption at the wastewater pumping station. The operators were

so impressed that they decided to purchase and permanently install the new

system at the facility.

https://utilitymagazine.com.au/flygt-concertor-trial-a-success-for-swedish-municipality/

Rene Prins discusses Flygt's new Experior wastewater pumping system, which

combines the best in hydraulics, motors and intelligent controls to deliver a

user-friendly, energy efficient wastewater pumping solution.

Water World Weekly video

interview

http://site-438305.bcvp0rtal.com/detail/video/1277219628001/flygt-a-xylem-brand

With the development of the centrifugal N-pump and

introduction of the PC-pump in the Flygt assortment ITT Flygt in 2008 was able

to offer a complete assortment of pumps for sludge applications.

McIlvaine Company Interview

http://www.mcilvainecompany.com/WEFTEC_2008/WEFTEC2008ITTFlygtCorporation.htm

K - Gorman-Rupp Pumps

Booth

3429

Gorman-Rupp Pumps is a manufacturer

of pumps and pumping systems for the municipal, water, wastewater, sewage,

industrial, construction, and original equipment manufacturing markets. Solids

handling self-priming and submersible sewage pumps offer maximum dependability

and ease of service. Established in 1933, Gorman-Rupp provides a quality,

competitively priced product backed by customer service.

Gorman-Rupp supplies sewage pumping systems including pumps, motors and controls

(complete sewage lift stations). The solids handling self-priming and

submersible sewage pumps offer

dependability and ease of service.

Struvite Choking Problems Solved:

SE Water decided to go with Gorman-Rupp Super T Series self-priming pumps with

an internal coating to attempt to slow the struvite growth. These pumps can be

installed above the liquid (high and dry) to enable operators to easily access

and monitor at ground level

https://www.pumpindustry.com.au/stps-struvite-pump-choking-problems-solved/

L - LobePro

Rotary Lobe Pumps Booth

4241

LobePro Rotary Pumps manufactures 3 lines of positive displacement, rotary lobe

pumps: S-Series: Sludge, Mud, and Slurries and General Use applications;

C-Series: Corrosives & Chemicals; and D-Series: Duplex Pumps for Abrasives &

Corrosives. Each line is also available in an API-Series: API 676 Compliant

version. Our rotary lobe pumps are typically used to pump sludge to and from

thickeners, separators (such as belt presses, centrifuges, and rotary presses),

digesters, clarifiers. They are

suitable for pumping any wastewater sludge which has had the hard solids over

1/8” and most grit removed for flows up to 2000 GPM and pressures up to 150 PSI.

the company can specify an in-line

grinder, filter or knock-out tank should hard solids larger than 1/8" be

present.

According to Bill Blodgett, president, the recent rate of innovation in

production from Biosolids has been amazing. However, one consistent requirement

is the need for low shear, pulseless pumping of viscous material (often

containing 2% or greater solids). Just as important is pumping at a measured

flow rate and pressure. LobePro rotary lobe pumps excel in this. LobePro pumps

are available in capacities up to 2000 gpm and pressure capability up to 150

PSI. The pumps are happy to run clockwise or counter clockwise. This allows one

pump to both load and unload or back flush. (for other properties see

Properties of Rotary Lobe Pumps).

M - Putzmeister America, Inc.

Booth

2857

Putzmeister is well known for its complete systems approach, especially for

handling the most difficult applications, including the transport and storage of

coarse sludges and slurries. From the mud of the Assuan Dam and the sewage

waters of Paris, to land reclamation, coal and ash in power stations, and gold

slimes in mining – Putzmeister is the first choice for municipal and industrial

project applications. Organic applications: biomass, sewage treatment,

co-incineration, coal slurry, cement industry, special waste, paper industry,

chemical industry. Inorganic applications: mining, fly- and bottom-ash, surface

water sludge removal, tunnel construction, oil industry/offshore. Putzmeister

technology has opened up new applications for difficult material, making it

possible to efficiently convey sludges and slurries that seemed impossible

before.

N - Shanghai Techase Environment Protection Co., Ltd

Booth

4651

TECHASE, which was invested in by Tongji University, is a worldwide leading

company in solid-liquid separation of industrial and municipal wastewater. Our

head office and factories are located in Shanghai. TECHASE intends to provide

customers with professional consulting services, the best cost-effective

solutions and products of top quality, high performance, and for customization.

O - Schwing Bioset, Inc.

Schwing

Booth

2914

Schwing Bioset, Inc. has supplied

complete biosolids treatment and handling systems for over thirty years. Growing

from a biosolids handling supplier, it now offer process systems as well,

including MBR systems, phosphorus management, screw press dewatering, piston

pumps, screw conveyors, Class A alkaline stabilization and drying technologies,

sliding frames, live bottoms, and more.

At wastewater plants utilizing anaerobic digestion, Struvite commonly forms and

creates issues with pipes clogging and equipment being damaged as a result of

scaling. Additionally, tanks can accumulate Struvite, which requires

periodic removal and creates an additional expense to plant operations. Schwing

Bioset’s Nutrient recovery system recovers Ortho Phosphate and Ammonia Nitrogen

from wastewater while offering great benefits to the treatment plant, not only

by significantly reducing phosphorus in the waste stream, but also preventing

unwanted scaling and accumulations, and creating a valuable end product.

The phosphorus forms a stable Struvite crystal that can be marketed and sold for

beneficial reuse, thus keeping excess phosphorus out of the local waterways and

helping close the phosphorus recycling loop.

White paper: Although the advantages of anaerobic treatment are obvious,

subsequent nutrient removal still remains an important issue. Readily

biodegradable organic matter needs to be bypassed towards aerobic post-treatment

in order to achieve the final nutrient effluent standards, thus reducing the

potential biogas yield

and increasing the waste sludge production. Nutrient removal by

struvite (MgNH4PO4 · 6H2O) or magnesium ammonium phosphate (MAP)

precipitation is an interesting alternative approach to address phosphorus

removal (von Munch and Barr, 2001; Gonzalez and De Sa, 2007).

To read the entire white paper, please submit the download form.

http://www.schwingbioset.com/white-paper-phosphate-removal

P - SRS Crisafulli, Inc. (also known as Crisafulli Pump Company)

Booth

7230

Full line of dredges for managing settled wastes, biosolids, sediment, lime and

alum sludges, and high-volume pumps for dewatering, stormwater management, lift

stations and pumps.

The SRS Crisafulli remote control FLUMP dredge is designed to remove settled

wastes and other by-products from settling ponds or lagoons. It is equipped with

discharge pumps in sizes 3", 4", 6", and 8". The integrated system is comprised

of major standard and optional components – i.e., flotation system, primary and

secondary motors, hydraulic and electrical systems, cutterhead, pump, ladder,

manual or programmable computerized controls, cabled traverse system, and

Crisafulli Integral Floating Discharge System. Four models are offered with

standard dredging depths to 12 feet. Custom depths to 30 feet.

https://www.waterworld.com/articles/print/volume-26/issue-6/products/products--services.html

O - Yamada America

Booth

645

Yamada Corporation is a global

producer of air operated double diaphragm pumps with over 100 years of

experience. It pursues an ever-increasing number of pump applications involving

corrosives, slurries, viscous and shear sensitive liquids. Pumps range from ¼”

through 3” in a wide array of materials of construction. Specialty pumps include

solids handling, powder, and high-pressure pumps.

U - Weir

Booth 5739

Weir designs and manufactures highly engineered pumps and related equipment for

the global water and wastewater industries. Engineers work closely with

customers to understand their operational challenges and help improve

productivity and lower total operating costs.

At Stand 5739, Weir will be displaying its full product portfolio for the water

and wastewater markets including products from Weir Floway and Weir Specialty

Pumps (WEMCO and WSP brands).

Weir Floway has been manufacturing vertical turbines for more than 80 years. We

are recognized by customers around the world for industry leading quality and

performance. We have evolved into an engineered-to-order company that can solve

the most complex and demanding of applications. From special materials and

custom designs, Weir Floway is dedicated to providing superior quality, top

hydraulic performance, and long service life.

Weir Specialty Pumps (WSP) are experts when it comes to wastewater pumping and

grit removal applications. WSP brings more than 60 years of experience in

providing equipment to the municipal wastewater market with our WEMCO

Torque-Flow recessed impeller grit pumps, WEMCO Screw-Flow screw centrifugal

solids handling pumps, and the WEMCO Hydrogritter for grit removal and

dewatering applications. In addition, WSP also manufactures the WSP Chop-Flow

chopper pumps, WSP Self-Primer, and WSP Non-Clog pumps. WSP is able to provide

pumps in a multitude of arrangements including horizontal, vertical, and

submersible.

Media and Pumps at WEFTEC

A - Magazines and Interconnection of People and Knowledge

The Industrial Internet of Wisdom interconnects people and knowledge through

publications, conferences, and webinars. These provide the support information

for the decision systems and Lowest Total Cost of Ownership Validation (LTCOV).

Transfer of knowledge from one industry to another is also important. Municipal

and industrial wastewater innovations need to be shared. There also needs to be

interconnection between the systems designers and the suppliers of components

and consumables. Various publishers exhibiting at WEFTEC make the

interconnection between industry e.g. industrial wastewater and municipal

wastewater or between products and industries e.g. pumps. Suppliers and

purchasers can pursue IIoW with their assistance.

|

Magazine |

Stand |

|

Chemical Engineering |

809 |

|

Chemical Processing |

542 |

|

Endeavor Business Media |

4051 |

|

Empowering Pumps |

4751 |

|

Environmental Science and

Engineering |

2246 |

|

Global

Water Intelligence |

6659 |

|

Modern Pumping Today |

5150 |

|

Pumps & Systems |

2852 |

|

Stormwater |

1652 |

|

WaterWorld |

3911 |

|

Water & Waste Digest |

4028 |

B - Endeavor Business Media

is offering industry and product interconnection. The Process Flow Network

covers innovative solutions for the process industries. Together, the three

brands that make up the network — Processing, Flow Control and Water

Technology — serve a diverse audience of engineers, corporate managers, plant

operators and other process industry professionals. You can learn more about the

Process Flow Network at WEFTEC Booth #4051.

C - Science & Engineering

has struvite data.

In November 2015, two HydroFLOW 160i units were installed on the sludge

pipe feeding the GEA Westfalia Separator model CB 505-00-32 centrifuge at

Somersworth N.H. One unit was placed before the centrifuge, just after the

thickened waste activated sludge pump, and the other was placed before the feed

tube just before the centrifuge. Both units were installed without process

down-time as they are fitted around existing piping and do not require plumbing

modifications.

The units use 120V AC and draw less than 1 Amp, which is similar to the power

consumed by a 60-watt light bulb.

Success for this facility meant reducing polymer usage and producing dryer cake,

while not adversely impacting the centrate quality. The centrate quality in

Somersworth typically averages about 500 mg TSS/L, but rarely exceeds 1,000 mg

TSS/L. Surpassing the 1,000 mg TSS/L threshold could affect the plant treatment

capacity.

https://esemag.com/wastewater/new-device-reduces-polymer-use-and-controls-struvite-during-sludge-dewatering/

D - Modern Pumping Today.

One of the recent feature articles covers struvite removal

https://modernpumpingtoday.com/removing-struvite-from-wastewater-systems/

The article above

on struvite removal at NYC with a special polymer was contrasted to an

approach which would have made centrifuge pond adjustments. This article

presents a third option.

A wastewater treatment company in Canada uses a number of

dewatering centrifuges to remove water from sewage sludge. After the sludge has

been removed the water is purified and then discharged. Purification occurs in

the sludge dewatering centrifuge where the centrifuge’s force separates the

sludge from the water.

Struvite formed inside the sludge dewatering centrifuge

necessitating the need for the centrifuge to be stopped and cleaned every 800

hours of operation (approximately two months) which took workmen a day to clear

with chemicals, hammers and chisels.

A Scalewatcher electronic descaling system was installed at the

centrifuge with an induction cable around the 6-inch supply mains. When, after

four months, the treated centrifuge was opened during the first inspection, it

appeared that the wall was only covered with a minimal deposit of softened

struvite. Two months later the centrifuge was opened and inspected again

whereupon it was found to be even cleaner. To confirm the results, the

Scalewatcher was switched off. Shortly afterwards, the operators noticed that

the deposits had returned. When the Scalewatcher was switched on again the

Struvite disappeared. The magazine covers municipal and other pumping

applications and includes in depth analyses which can aid decision making. Vince

Marino

vince@modernpumpingtoday.com

will be at the stand 5150

E -

WaterWorld Stand 3091 has an easily used search engine. A search

under struvite shows a 2018 article -

Howard County Department of Public Works engaged HDR to provide engineering

design services for upgrades to the biosolids facilities at the Little Patuxent

Water Reclamation Facility in Savage, Maryland. The Little Patuxent facility

used dewatered cake lime stabilization for biosolids treatment. The changes to

the biosolids processing included eliminating the lime system and replacing it

with anaerobic

digesters, centrate demmonification and associated solids

screening, thickening, odor control and digester gas handling improvements.

After an extensive evaluation of phosphorous removal

technologies, the design was based on Centrisys AirPrex because of its

demonstrated ability to prevent struvite precipitation in downstream processes,

including piping and the solids dewatering equipment. The Little Patuxent

facility uses decanter centrifuges for biosolids

In a 2017 article in WaterWorld - CNP™

Technology Water and Biosolids Corp.

recently announced

AirPrex®,

a

sludge optimization and phosphorus

recovery process, has been selected

for the Liverpool Wastewater Treatment Plant (WWTP) by the Medina County

Sanitary Engineers in Ohio.

A comprehensive article on nutrient recovery in a 2016 issue is provided at

https://www.waterworld.com/articles/wwi/print/volume-31/issue-6/featured-articles/nutrient-recovery-2-0.html

This article is from the sister publication, Water & Wastewater International by

Dr. Christian Kabbe

from the Berlin Centre of Competence for Water, Germany.

For more information, email:

Christian.kabbe@kompetenz.wasser.de.

The struvite problem and the interest in nutrient recovery is world-wide.

The quest for the LTCO

should also be world wide

Note Also view the automation

N-Hach web recording which is by WaterWorld and the automation-N Suez TOC

analyzer article which appeared in WaterWorld pre show coverage as well as the

pumps and valves E-NOV progressing cavity pump

F - Water & Waste Digest

Stand 4028 has a search engine with multiple articles on struvite. Here

is one from 2017 -

Struvia prevents uncontrolled struvite precipitation during

wastewater treatment. This Veolia process uses a patented mixing system,

TurboMix, to produce and separate struvite crystals within a single reactor.

This compact, resource-efficient, low-energy process saves on operating costs by

reducing struvite-related maintenance and reducing the amount of coagulant used

for chemical P removal, all while producing a valuable granular end product

consisting of magnesium ammonium phosphate crystals that are rich in recycled

nutrients.

https://www.wwdmag.com/treatment/struvite-removal

G - Chemical Engineering

The September issue will be distributed at WEFTEC.

There is a special advertising section on water treatment but the feature

articles are on boiler feedwater treatment. Advertisements for some WEFTEC

exhibitors appear in the main section but there are advertorials for each in the

special water treatment section.

Each of these is the equivalent of 0.5 pages of advertising.

So for GEMU, Flottweg and about half of the listed advertisers there is

the bonus coverage.

|

Chemical Engineering September

2018 CFT Advertising |

||

|

Company |

Pages |

Subject |

|

Cleaver Brooks |

1 |

Boilers, water systems, controls |

|

Emerson |

1 |

Engineering and project

management-automation |

|

Endress +Hauser |

1 |

Flow meters, transmitters, pH |

|

Badger Meter |

1 |

Flow meters |

|

Flottweg |

0.5 |

Centrifuges |

|

Ross |

0.5 |

Mixers |

|

Load Controls |

0.5 |

Viscosity measurement |

|

Gemu |

0.5 |

Valves, water treatment |

|

Swagelok |

1 |

Valves |

|

NOV |

1 |

Progressing Cavity Pumps,

screens, mixers |

|

Krohne |

0.5 |

Level transmitters |

|

Ekato |

0.3 |

Mixing |

|

A-T controls |

0.2 |

PFA lined ball valves |

|

Material Transfer |

0.5 |

Bulk bag discharger |

|

Paul O. Abbe |

0.2 |

Mixing, size reduction |

|

Proco |

0.2 |

Check valve |

|

Seepex |

0.5 |

Pumps , metering system |

|

Bionomic |

0.5 |

Modular scrubbers |

|

Ametek |

0.3 |

Viscosity analyzer |

|

Finder Pompe |

0.3 |

Centrifugal and plunger pumps |

|

Myron L |

0.5 |

Liquid measurement |

|

Arkema |

0.5 |

Kynar |

Determining Competitor Market Shares and Strategy

The McIlvaine Company provides market share data for nearly 1000 pump companies.

However clients are seeking even greater segmentation by industry, region and

specific product.

One of the tools for this more extensive segmentation is activity at

exhibitions. The geographic distribution as well as industry focus can be

determined. The detailed analysis

of exhibition activity at WEFTEC is shown at

Municipal Wastewater Services.

There were many water related exhibits at Singapore International Water

Week. We have a 20 page analysis just of the pump companies with displays.

We have been analyzing exhibition activity every third year for IFAT in

Munich and were a participant in the Pump Summit last year.

We have also just completed an analysis of exhibitors

at Filtration 2018.

The focus is on air filtration, gas turbine, and

dust collector media with a more minor focus on liquid filtration and no

focus on pumps. By contrast.

Filtech held in Europe is more focused on filtration equipment rather than media

and has the largest display of filtration equipment of any show around the

world.

A number of power related shows are reported in our

Utility E Alert including smaller

venues such as the VGB air pollution conference or the Indian FGD & DeNOx

conference last week. Power-Gen

shows in several regions of the world

include substantial pump space.

The OTC exhibition in Houston is one of the largest oil and gas

exhibitions with a number of pump exhibitors. Interphex in NYC has a handful of

displays by pharmaceutical pump

suppliers. ACHEMA in Frankfurt

provides hundreds of displays of pumps for the chemical industry every third

year

The Cleanroom Technology exhibition in the U.K and a number of smaller European

exhibitions such as Lounges provide displays of pumps used in cleanrooms.

The industry focused shows such as Semicon West have some displays by

pump suppliers but the pump percentage of total

space is low.

Advertising is also a good indicator of activity by product, industry and

location. We tabulate the number of

pages, the subject matter and the service in which we will be evaluating it.

|

Pump Advertising in

Pharmaceutical Manufacturing

July-August 2018 |

|||

|

Company |

# of pages |

Subject |

Service |

|

None |

|||

|

CFT Advertising in Processing -

October 2018 |

|||

|

Company |

# of pages |

Subject |

Service |

|

Discflow |

0.5 |

Pump |

Pump |

|

Blue-White |

1 |

Pump, Flow Meter |

Pump, IIoT |

|

Gorman Rupp |

0.2 |

Pump |

Pump |

|

Motion Industries |

1 |

Pump |

Pump |

|

NOV |

1 |

Pump |

Pump |

|

Hydrocarbon Processing -

September 2018 - Advertising |

|||

|

Company |

Pages |

Subject |

Service |

|

No Pump Advertisements |

|||

|

Chemical Engineering - September

2018 - CFT Advertising |

|||

|

Company |

Pages |

Subject |

Service |

|

Seepex |

0.5 |

Pumps, Metering System |

Pumps |

|

Finder Pompe |

0.3 |

Centrifugal and Plunger Pumps |

Pumps |