|

Sludge Dewatering, WEFTEC, and the Industrial Internet of Wisdom

WEFTEC should be bigger and better than ever this year and maybe even exceed the record attendance in Chicago last year. Here are the details:

WEFTEC 2018

91st Annual Technical Exhibition & Conference

Conference: September 29 - October 3

Exhibition: October 1 - 3

Core Hours: 8:30 am - 5:00 pm daily

New Orleans Morial Convention Center

At the 2013 WEFTEC McIlvaine prepared a Global Decisions Positioning Guide (GDPS) informing visitors of all the WEFTEC resources with insights on obtaining better sludge dewatering. Here is that link:

www.mcilvainecompany.com/Decision_Tree/subscriber/Tree/DescriptionTextLinks/Municipal%20Wastewater%20Flow%20and%20Treatment%20GdPS%20at%20WEFTEC%202013.htm

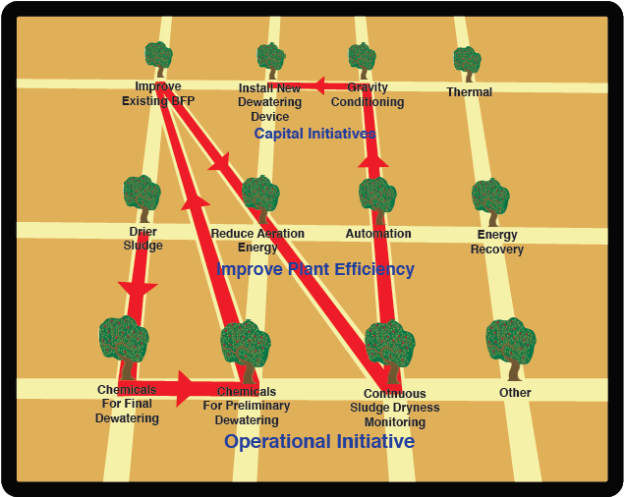

This guide provided locations and times of relevant speeches as well as booth location of exhibitors who could impact sludge dewatering. It starts with simple adjustments to dewatering equipment, change in quantity and type of treatment chemicals, as well as monitoring, automation and addition of new dewatering devices.

This is all part of the Industrial Internet of Wisdom which is a McIlvaine initiative to connect people and knowledge. One of the included services is Municipal Wastewater Decisions.

We will be preparing a new guide for the 2018 show. This guide will be posted on September 13th. In the meantime we are encouraging exhibitors, speakers and others to help us prepare the Sludge Dewatering GDPS.

To contribute information for the Sludge Dewatering WEFTEC GDPS contact Bob McIlvaine at rmcilvaine@mcilvainecompany.com 847 784-0012 ext 122.

IIoT and Remote Monitoring is already improving sludge quality at Village Creek

The positive benefit of IIoT and Remote Monitoring in conjunction with water treatment chemicals was the subject of a McIlvaine webinar last year. This can be viewed at https://youtu.be/YD5C93c6ujw

The webinar included a presentation by Kemira on the merits of controlling treatment chemicals based on multiple parameters.

Village Creek’s wastewater flow averages 100 million gallons per day, and initial sludge flows to the Renda Environmental dewatering facility averaged 1,000 gallons per minute. In late 2014, the Renda facility started to suffer from deteriorating dewatering performance. Cake solids were wetter and malodorous than before, which led to increased hauling costs and complaints by the residents due to the odor. Additionally, struvite started to build up in the sludge grinders and on the belt filter presses, increasing the maintenance costs.

Kemira introduced a flow-paced dosing of chemistries to account for variances in the sludge flow. A real-time total solids meter was installed prior to the coagulant application point for an option to dose the chemical on a pound per dry ton of sludge basis with the sludge flow taken into account. A second real-time monitoring device was placed after the iron salt feed to dose the polymer accordingly.

Kemira Application Manager Tafadzwa “Tee” Mariga notes that the client’s problems were due to the Village Creek wastewater treatment plant starting to receive sludge that contained poly-aluminum chloride from smaller local wastewater treatment plants. In this situation, the sludge held more water than earlier, when the local plants had used ferric sulphates.

“Our team came to the conclusion that the best solution was a combination of appropriate chemistry and SMART technology. It is the specific combination and way of dosing inorganic coagulants, in this case an iron salt, with the organic flocculant (polymer) that resulted in an improved dewatering performance, odor control and struvite control,” notes Tee.

“Our technologies allowed for the plant to dose chemicals as per demand. This SMART chemical treatment of the sludge enables the optimization of the chemical consumption and always delivers the best dewatering performance, even if the input sludge properties vary over time.”

The solution proved to be very effective, and results were quickly available. “The beauty of dosing the right chemistry combination with a controlled program is that you see the benefits quickly. The belt press cake went from being sloppy to crumbly once the chemistry went through the system. It worked like magic,” Tee recalls. Showing significant improvement, the site increased the belt press cake solids by 5%Renda’s hauling costs were remarkably decreased, considering that the drier sludge cakes made it less expensive to transport them. In addition, struvite build-up on belt presses was reduced, which diminished the maintenance costs. Since the start of this SMART dewatering, Renda has had no odor complaints, which is saving the company significant costs as each odor complaint reported costs at least $2000.

“The advantage of the value-added program is that the chemistry combination allows the selection of some benefits over others. For example, Renda had an option to keep the polymer dosage the same and the coagulant allowed them to increase their belt press throughput by at least 20%. This enables savings in labor, electricity and equipment run time,” Tee concludes.

Other benefits included reduced belt press filtrate ortho-phosphate levels (over 90%). The belt press filtrate is returned to the head works of Village Creek and so this reduction has had a positive effect on the overall plant treatment process. The plant manager’s claim that they have witnessed improved settling rates in their primaries and that they are treating less water. The improved filtrate quality has also qualified Village Creek to sell their reuse water to the local airport for machine cleaning.

A number of Kemira people will be at WEFTEC. The best contact as a starting point will be Tafadzwa “Tee” Mariga, Applications Development Manager – AWT | Industry & Water | NA, tafadzwa.mariga@kemira.com, +1.817.875.3665.

Sludge Dewatering and IIoT

The Sludge Dewatering Guide is included in Municipal Wastewater Decisions. The WEFTEC Sludge Dewatering GDPS is part of the guide initiative. The potential for sludge dewatering improvements through IIoT and Remote O&M are substantial. The Village Creek Wastewater plant example above shows this potential.

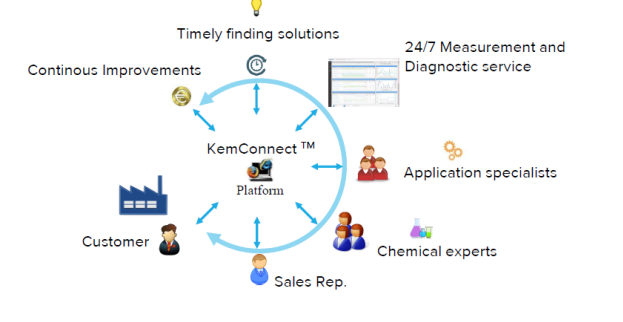

Taking this to the next step includes process management programs and 24-7 monitoring. In the McIlvaine IIoT Water Treatment Chemicals Webinar (see this at https://youtu.be/YD5C93c6ujw ) the programs already underway for 24-7 monitoring and support by Nalco, Solenis and others are examined. The following Kemira diagram shows the basics:

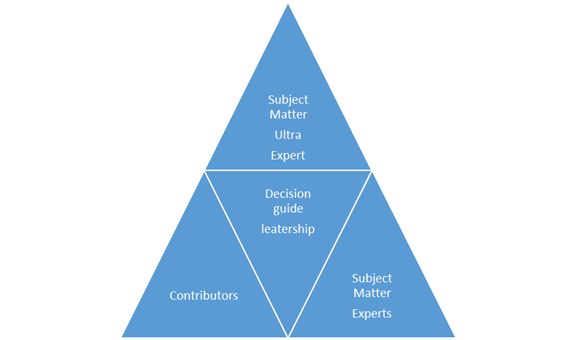

The experts on the chemicals are personnel at the chemical companies as well as individuals at consulting companies and the municipalities. The experts on applications include people at the dewatering, pump, valve, instrumentation, compressor and other supplier companies. Andritz supplied the dewatering equipment at Village Wastewater. It also supplies process management and subject matter expertise. It will be exhibiting at stand 1829. Interconnecting the Andritz and Kemira experts and knowledge is highly desirable. Municipal Wastewater Decisions is a program which facilitates the development and access to this expertise. There is an expertise hierarchy

Expertise contributors include thousands of people who have niches of knowledge in narrow areas.

Subject matter experts (SMEs) are proactively developing the areas of niche expertise. Subject matter ultra experts (SMUEs) are individuals who are actively participating and leading analysis of a niche area in the Municipal Wastewater Decisions.

The WEFTEC Sludge Dewatering GDPS will provide stops at automation and software companies as well as consulting company stands which would be a source of niche expertise and 24/7 support programs. The WEFTEC conference and exhibition is an opportunity to provide interconnection of the knowledge and people relative to dewatering decisions. Decisive classification of options is one outcome. More broadly it is the leveraging of the Industrial Internet of Wisdom which will empower IIoT.

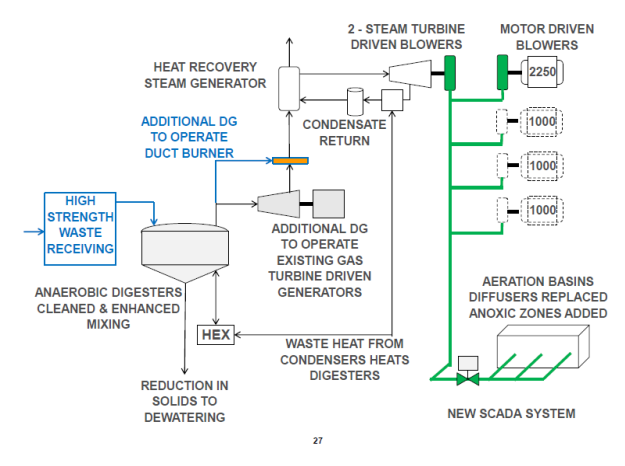

One of the knowledge interconnections is a paper at Michigan WEA “Steam Powered Energy Conservation at Fort Worth’s Village Creek WRF. The authors are Peter Caganaro of Johnnson Controls, Andrew Cronberg of City of Fort Worth and Alan Bush of AECOM. The paper describes the project to utilize biogas to generate electricity but also other improvements to reduce the solids needing dewatering. A process management system with a holistic approach not only achieves better sludge but reduces the amount of sludge.

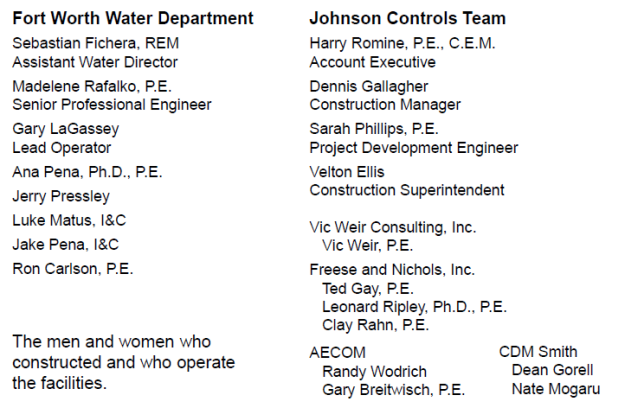

We will be contacting various individuals involved in this project to see if they will be at WEFTEC and if they would be interested in discussing it with others. They include:

We will also determine who at the Emerson stand 6739 can talk about the SCADA upgrade to Ovation DCS. Also Emerson has an actuator stand 8121 with relevant information.

VanLare installs Pulsafeeder metering pumps

Located on the southern shore of Lake Ontario, the Frank E. VanLare Wastewater Treatment Facility, Monroe County, N.Y., has a total treatment capacity of 660 mgd and is currently running around 100 mgd. The plant uses Non-metallic Eclipse pumps to pump 12.5% Sodium Hypochlorite, Chlorine, for disinfection before the final discharge of the wastewater. VanLare runs 24 hours a day, 365 days per year.

VanLare originally installed peristaltic pumps for Sodium Hypochlorite and its Environmental Service team was in search of a better solution. Peristaltic hose life is unpredictable and inconsistent. These pumps are not leak free so worker safety was also a concern because of inhalation and skin contact with the chemicals. To solve the problem they installed Non-metallic Eclipse pumps. Eclipse sealless design ensures zero emissions of hazardous or regulated chemicals. These pumps have superior chemical resistance. Service is quick and piping and electrical stay in place because of the front pull-out design.

In addition to pumping Sodium Hypochlorite, VanLare installed three Non-metallic Eclipse E25 pumps into the Ferric Chloride station. Ferric Chloride is used for phosphorus removal. Pulsafeeder will be a stop in the Sludge Dewatering WEFTEC GDPS at stand 4308.

Accudyne will be a stop at the Sludge Dewatering WEFTEC GDPS

Accudyne Industries business units manufacture pumps designed to inject coagulants, disinfectants, softening agents, acids and bases for pH control and de-chlorination chemicals into a plant’s water systems:

Milton Roy metering pumps are efficient, cost-effective and reliably designed specifically for wastewater treatment.

Milton Roy mixers are widely utilized for basic treatments, sludge digestion and O2 injection.

Williams pneumatic metering pumps are ideally suited to precisely inject a wide variety of chemicals designed for treating industrial water and wastewater.

LMI chemical metering pumps are used for versatile applications in water and wastewater treatment.

Sunflo high pressure centrifugal pumps are widely utilized for boiler feed water and membrane filtration wash down.

The Milton Roy stand at WEFTEC will be 3739 and they will be one of the identified stops in the Sludge Dewatering WEFTEC GDPS.

Thames Water Modgen plant switches to SEEPEX pumps

Originally built in the 1930s, the Mogden sewage treatment plant has undergone major expansions over the decades to keep up with exploding population growth. Operator Thames Water has now converted the large plant over to using SEEPEX pumps. The customer needed more than just equipment, requesting a sophisticated service package as well to ensure optimal operation.

This was no small challenge given the variety of sludges involved of differing densities and temperatures. SEEPEX had to precisely design every pump – ranging from the small metering pump for liquid polymers to the many transfer pumps for sludge treatment – for specific requirements. Pumps also had to be developed which were capable of moving 180 cubic meters of slurry to the sludge treatment facility 16 km away. Additionally, special measures were required to ensure smooth and efficient pump operation, reducing downtime and costs.

SEEPEX N300-36 transfer pumps were deployed, becoming milestones in technological development by being the biggest progressive cavity pumps in existence at that time in both length and weight.

Since commissioning, SEEPEX has performed full-service monthly inspection and maintenance of the pumps, checking dry running, overpressure, wear, driving power and efficiency. The key is performing preventive maintenance, on site and the same day if necessary, before any breakdowns can occur.

The success is evident, as pump downtimes at the sewage plant have been drastically reduced. SEEPEX UK is now responsible for maintaining a total of 68 progressive cavity pumps and macerators at Thames Water facilities and at the neighboring Iver South sewage treatment plant located in Slough.

Seepex is one of the identified stops in the Sludge Dewatering WEFTEC GDPS at stand 6939.

Speakers

Sebastian Smoot of HDR will be discussing Bio solids Process Centralization at 2:30 pm on Tuesday.

Other relevant papers will be included in the final GdPS

Aerator Blower GDPS at WEFTEC

Municipal Wastewater Decisions includes a very detailed analysis of aerator blower types and the benefits and limitations of each relevant to specific conditions and processes encountered in municipal wastewater plants.

http://www.mcilvainecompany.com/MWT_Decisions/Subscriber/Aeration%20Blower%20Purchasing%20Decisions.pdf

One of the main theses of the decision guide is the replacement of large blowers with smaller ones. The reason is that with fluctuating flows it is cost efficient to run smaller blowers as needed. In the ‘Village Wastewater case the decision was made to convert to large unused blowers to operate with steam powered drivers. So this paper will also be linked in the blower purchasing decision guide.

A number of aerator blower suppliers will be on hand at WEFTEC. Among them will be Howden-Roots. In the past McIlvaine has had extensive discussions with them on related subjects. They will have a unique perspective on steam powered blowers particularly in light of their recent acquisition of a Siemens blower company.

Here are the aerator blower exhibitors

|

Atlas Copco

|

4837

|

|

Aerzen

|

817

|

|

APG Neuros

|

3407

|

|

Gardner Denver

|

7039

|

|

Howden

|

1117

|

|

Pillaerator

|

4107

|

|

Sulzer

|

2515

|

John Koch of HDR will be presenting the case for a more expensive aeration blower on Tuesday at 11:30 am.

Details on new options will be included in the final GdPS

Other relevant papers will be included in the final GdPS

Best Practices will also cover wastewater aeration

Improving plant profitability by optimizing compressed air systems is the focus of the inaugural 2018 Best Practices EXPO & Conference, to be held at the Chicago O’Hare Crowne Plaza Conference Center, September 17-19, 2018. Compressed Air Best Practices® Magazine Publisher Rod Smith said, “After 11 years of publishing “Best Practice” stories, we’re thrilled to create an opportunity for our subscribers to share knowledge and view technology in-person.”

One of the opening sessions will be on municipal wastewater optimization. Speakers will incude Tom Jenkins of Jentech on understanding blower control efficiency parameters, Stephen Horne of Kaeser Compressors talking about blower system integration; John Conover of Atlas Copco on the fundamentals of different blower technologies; and Eric Bennett of Aerzen on pressure, flow and ammonia dissolved oxygen control.

On Tuesday Roger Blanton of Howden will be discussing blowers for pneumatic conveying.

More details on the conference and exhibition are available at https://cabpexpo.com/conference/

Lift Station Valves furnished by DeZURIK to Phoenix

APCO SRA Surge Relief Angle Valves were installed on a new Lift Station in the city of Phoenix. New freeway construction required the existing lift station to be relocated. The new location is in a hilly part of town with elevation changes, and the Lift Station discharges into a force main system. The 8” SRA-3000A Surge Relief Angle valves are designed to prevent line damage from surges that occur when the lift station pumps cycle on and off. The surge valves were installed and set to relieve system pressure at 135 psig. DeZurik PEC Eccentric Plug Valves are used as isolation valves on the lines.

The surge relief valve is typically installed downstream of the check or pump control valves on the pump discharge header with the valve inlet connected to the side outlet of a tee and the valve outlet piped to the sump. The normally closed surge relief valve opens quickly when the system pressure rises above its adjustable relief pressure setting allowing fluid to be discharged from the system through the open surge relief valve to atmosphere. While the surge relief valve is open, the system is no longer contained, fluid compression is limited and surge pressure is controlled (green line). The valve will remain open as long as the system pressure exceeds the valve’s relief pressure setting. The valve will slowly begin to close at an adjustable rate as the surge pressure subsides and the system pressure falls below the valve’s relief pressure setting. DeZurik will be at stand 4929 at WEFTEC.

Crane-Barnes pump solves lift station clogging problem

The Town of Salem is a small, rural community, with a population of 12,036, located in southeast Wisconsin. The municipality manages 25 lift stations. Lift station #18 is a triplex station and was clogging weekly mostly due to flushable wipes according to multiple operators for the town. Brad Zautcke, Utility District Manager, explained that his team had to enter the station and unclog the pump by pulling out the rags with needle nose pliers. Due to the design of the station, it required entry into the station rather than removal of the pump, which meant a confined space entry with a three man crew. Each service call became a significant drain on the town’s resources and budget, each clogging maintenance trip cost a minimum of $300. The problematic pump was located farthest from the influent channel, so operators switched the position of the pumps, but that had no effect. The municipality worked with Energenecs, a Crane Pumps & Systems channel partner, on possible solutions. Crane Pumps & Systems provided a Barnes 4SHVA 30HP Solids Handling pump as a demo replacement for the station in September, 2013. The pump was installed a month later. The next time the pump was pulled was October, 2014 for its annual maintenance. Today’s non-biosolid laden wastewater requires new technology to keep the stream flowing. The Barnes SH Series with its non-recessed vortex impeller was the easiest, and it turned out to be the best option for Salem. It is estimated that the pump paid for itself in the first six months of operation.

Crane Pumps & Systems will be exhibiting at WEFTEC stand 4517.

Bob McIlvaine

President

McIlvaine Company

Ph: 847-784-0012 ext. 112.

Cell: 847-226-2391

www.mcilvainecompany.com

|