Webinar on June 26 Will Aid in Your CCR and Effluents Decisions

A high level discussion on coal combustion wastes and liquid effluents will be

based on data published on a new website CCR and Effluents – Continuous

analysis. The purpose is to help coal-fired power plant operators make

decisions about how to meet the proposed CCR and Effluent standards. The

challenge is interdependency. A decision on one aspect changes the options for

another. It is the equivalent to a trip where you have to keep backtracking and

changing course based on what you find at each stop. The equivalent of a GPS

tool would be helpful. This is what has been created with the CCR and

Effluent Global Decisions Positioning System™ (GDPS)

CCR and Effluent Standards GDPS

The proposed effluent guideline rule and the proposed CCR rule have to be viewed

together. Douglas J. Dahlberg PE, Project Associate II at Sargent &

Lundy LLC, in a recent McIlvaine webinar, anticipates a final rule to

classify CCRs under Subtitle D, Resource Conservation and Recovery Act (RCRA),

similar to Municipal Waste. The June 7, 2013 Code of Federal Regulations,

Effluent Limitations Guidelines (ELG) and Standards for the Steam Electric Power

Generating Point Source Category Proposed Rule stated, “reliance on (current)

data… coupled with the ELG proposed requirements could provide strong support

for a conclusion that regulation of CCR disposal under Subtitle D would be

adequate.” Speculation on final regulation publishing timing ranges from

October 2013 to the end of 2014.

Whether your current disposal operation is wet or dry bottom/flyash/FGD

byproducts, above or below grade, permanent disposal or transfer, your basic

choices include:

·

Close and cap your current disposal operation.

·

Transition the existing site to comply with new requirements.

·

Develop a separate new compliant disposal facility.

·

Regardless of whether your existing disposal site is lined, monitored or impacts

groundwater, the best option may be to combine the disposal options.

Doug made a convincing argument that you can maximize the use of your existing

site by depositing the new waste over the one which has already been covered and

capped.

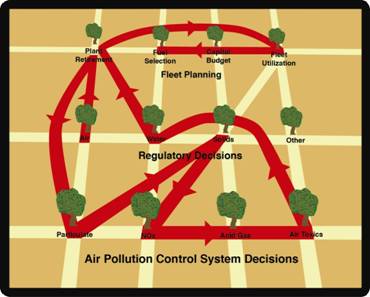

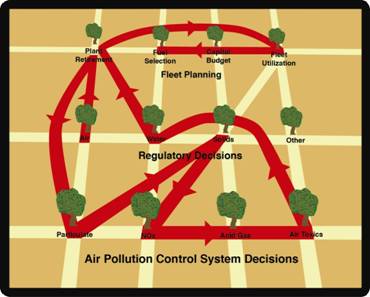

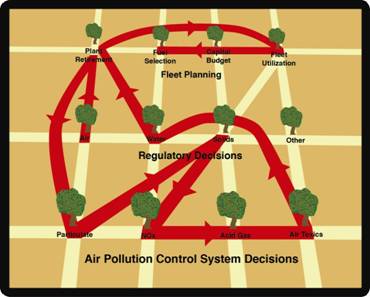

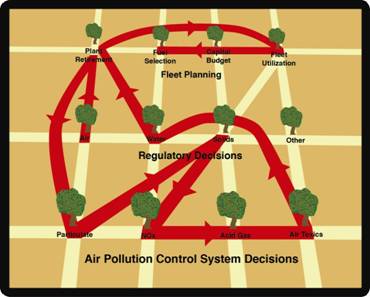

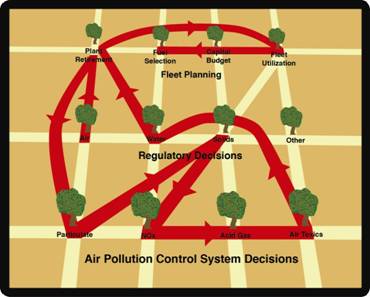

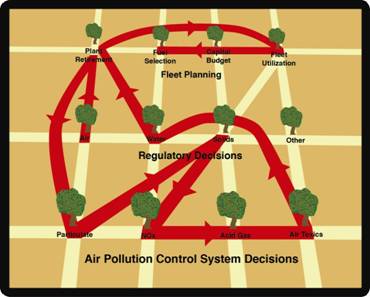

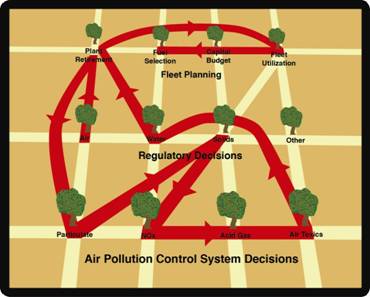

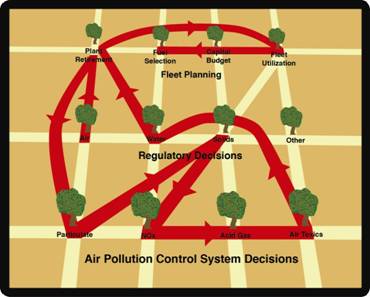

Decision Trees in ELG-CCR GDPS Route Map

ELG

Regulations

ELG

Regulations

![]()

CCR

Regulations

CCR

Regulations

Wet

Air Pollution Control

Wet

Air Pollution Control

Bottom

Ash Handling

Bottom

Ash Handling

Wastewater

Treatment

Wastewater

Treatment

Flyash

Handling

Flyash

Handling

The ELG regulations will be issued first and will shape the CCR decisions, so

this is a starting point. However, it may be necessary to review the ELG

regulations in light of any CCR regulatory insights.

![]() 1st

Decision Tree Stop: ELG Regulations

1st

Decision Tree Stop: ELG Regulations

With respect to ELG requirements for surface impoundments that are used to

manage CCRs, EPA is considering establishing best management practices (BMPs)

that address impoundment construction, operation and maintenance to prevent

uncontrolled discharges Id. at 34,458. The BMPs that EPA is

considering would require plant operators to conduct periodic inspections of

active and inactive surface impoundments and to take corrective actions where

warranted. Inspections would be conducted every seven days by a person qualified

to recognize specific signs of structural instability and other hazardous

conditions by visual observation and, if applicable, to monitor instrumentation.

Dennis Fink, CH2M HILL outlined the challenges in a previous

McIlvaine hot topic discussion.

Click here for Dennis' presentation at a McIlvaine Hot Topic Hour in 2012.

2nd

Decision Tree Stop: CCR Regulations

2nd

Decision Tree Stop: CCR Regulations

Since the close of the comment period on the CCR rule, EPA has received new data

through a 2010 Information Collection Request. EPA now has

facility-specific data from the 495 coal-fired power plants in the U.S. that the

Agency says have the potential to affect its final risk assessment. The

new data reveals that the impoundments and landfills are generally smaller than

the impoundments and landfills included in the assessment to support the

proposed CCR rule. According to EPA, the new data and analyses “may have the

potential to lower the CCR rule risk assessment results by as much as an

order of magnitude.” EPA continues: “If this proves to be the case,

EPA’s current thinking is that, the revised risks, coupled with the ELG

requirements that the Agency may promulgate, and the increased Federal oversight

such requirements could achieve, could provide strong support for a conclusion

that regulation of CCR disposal under RCRA Subtitle D would be adequate.”

So we will be keeping abreast of the latest on these regulations

3rd

Decision Tree Stop: Wet Air Pollution Control

3rd

Decision Tree Stop: Wet Air Pollution Control

One of the options is utilize natural oxidation instead of forced oxidation FGD.

The soupy sludge encapsulates the heavy metals. When you add lime to this mix

you create a chemically fixed product which is less leachable than gypsum.

So you have to consider the FGD options.

![]() 4th

Decision Tree Stop: Bottom Ash Handling

4th

Decision Tree Stop: Bottom Ash Handling

There are various technology solutions to the bottom ash problem Ron Grabowski,

Vice-president Business Development at Clyde Bergemann Power Group

Americas, Inc., Materials Handling Product Division, discussed the

handling of bottom ash in a recent McIlvaine webinar.

He explained all the options including one which eliminates the use of any

water.

1.

Divert the flow of the existing bottom ash slurry piping to new dewatering bins.

2.

Divert the flow of the existing bottom ash slurry piping to a remote submerged

scraper conveyor (RSSC) system (ASHCON™).

3.

Replace the bottom ash hopper system with a submerged scraper conveyor (SSC).

4.

Replace the bottom ash hopper system with a dry ash conveyor (DRYCON™).

One more option is to make a unique by product Dale Timmons, R.G., Business

Development Program Manager at NAES Corporation, discussed the

Circumix Dense Slurry System (DSS) technology in a recent McIlvaine webinar.

NAES Corporation and GEA EGI have teamed to deploy DSS technology

in North America. DSS is a proven and commercially deployed technology that uses

wastewater (including FGD water) to stabilize ash products.

![]() 5th

Decision Tree Stop: Wastewater Treatment

5th

Decision Tree Stop: Wastewater Treatment

There are a number of sources creating to wastewater contamination in a coal

fired power plant. The options include zero liquid water discharge.

Water is purified for re-use and evaporators convert the slurry into a solid

waste.

6th

Decision Tree Stop: Flyash Handling

6th

Decision Tree Stop: Flyash Handling

Sale of flyash is one of the best options, but this is contingent on the coal

type and access to markets. If the solution to the MATS is to add dry

scrubbers or DSI followed by a baghouse, then the flyash is going to be mixed

with calcium sulfate and will not be salable. One option is to mix the flyash,

calcium sufate sludge with about 2 percent of extra lime and create a chemically

fixed disposable product. Gordon Maller of U.R.S. discussed this option in a

recent McIlvaine webinar. His power points are included on the site.

Flyash needs to be transported from the precipitator or baghouse by pneumatic or

mechanical conveying. There are options among the various types of

pneumatic systems as well.