HOT TOPIC HOUR

Mercury Hot Topic Hour unveils New Findings and Options

The Hot Topic Hour on July 23 was a high level discussion of new developments over the last few months and updating of a Route Map and Summary of the issues and options.

Only a few of the hundreds of subjects contained in the decision system were addressed yesterday. Mark Bleckinger of Black & Veatch described a whole program based on parametric testing resulting in the best choices for mercury reduction. All of the following have to be considered.

The success of activated carbon injection directly into the scrubber was chronicled by Dave Murphy of Steag.

This success has been duplicated by ADA-CS.

Bromine characteristics for mercury control, according to Jon Lehmkuhler are

§ Low operating and capital costs

§ Reduced risk of flyash impact for sales

§ Ability for adjustment with changing plant conditions

§ Bromide investigated for downstream equipment impacts because of its value for mercury oxidation for control technologies (EPRI).

o No corrosion has yet been directly or solely attributed to bromide

o Air Heater impacts are most prevalent at the cold side

o Other factors being investigated for contribution to corrosion

§ Air Heater temperature, soot-blowing, and MOC adaptations being investigated for ways to control corrosion at vital equipment.

§ Low sulfur coals, Air Heater temperature effects, bromide addition rates, and other contributing factors (load changes, additives, etc.) investigated. Some trends on how to operate with bromide.

§ Investigation of Pre-boiler bromide impacts demonstrates:

o No corrosion rate concerns – applications determine required performance

o Carbon steel shown to have most effect, stainless and Duplex performed well

o Temperature effects

o No weld impact and most impact observed in liquid, no issues at vapor/ liquid interface

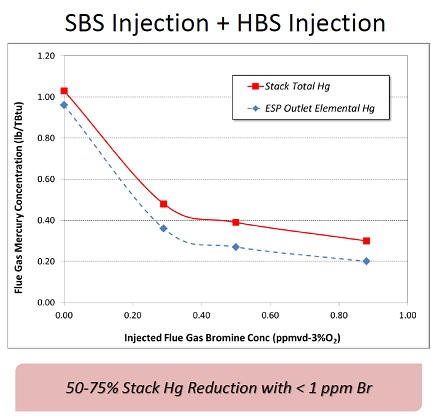

Sterling Gray of AECOM unveiled test data which show beneficial effects of adding both bromine and SBS.

The question was posed as to whether the addition of SBS reduced bromine corrosion of the air heater. No one had a direct answer but it seems logical. EPRI is studying the bromine corrosion issue but it would seem that since adding sorbent ahead of the air heater is very attractive for many reasons, the bromine corrosion should be viewed in this operational mode.

Data supplied by Steve Baloga of Novinda shows higher additive cost but savings in flyash sales which more than offset the additive differential.

Nick Pollack of CoaLogix informed us that mercury oxidation is driving decisions to replace catalyst. However, catalyst replacement can be delayed by several modes including a more efficient catalyst in terms of mercury oxidation or by adding another catalyst layer. Switching from plate to honeycomb catalyst is another solution but only if deposition does not increase.

John Knotts of W. L. Gore, showed a second version of the mercury control module. Where a dry scrubber is used for SO2, Gore can furnish a direct evaporation system to cool the gas down to 200°F prior to the module. This design is being applied on sewage sludge incinerators and other smaller applications. The big applications to date have been with wet scrubbers in coal-fired power plants. Fort Martin and Cayuga are two the most recent.

This webinar continued to validate that the MATS limit can be obtained by multiple routes and at reasonable cost. Continuing development is leading to cost reductions.