“Power Plant Cooling Towers and Cooling Water Issues” was the Hot Topic Hour on May 23, 2013.

Power plant cooling presents regulatory and technical challenges. The issues and some of the solutions were effectively provided by four speakers.

Brad Buecker, Process Specialist at Kiewit Power Engineers, addressed “The Influence of Tightening Regulations on Cooling Water Treatment.” Once-through cooling is no longer a consideration for new and planned power plants, primarily due to pending 316a and 316b regulations. Rather, we almost exclusively see cooling towers or air-cooled condensers as the choice for steam condensation at combined cycle power plants. However, tightening regulations on the quality, and sometimes quantity, of power plant wastewater streams are influencing cooling tower treatment programs. One of the challenges covered in the presentation was micobiological control. Brad presented the following points for consideration:

Brett DeRousse, National Account Manager for Hydrolox, discussed “Potential impacts of 316(b) regulatory controls and their affects on existing power plant cooling water intakes.” Nearly half of the U.S. utility-owned electric generating capacity is cooled by once-through cooling systems. These power plants withdraw cooling water primarily from surface water bodies. Section 316(b) of the Clean Water Act requires that the location, design, construction and capacity of cooling water intake structures reflect the best technology available (BTA) for minimizing adverse environmental impacts. The selected BTA is likely to be Modified Traveling Water Screens (TWS) for many of the affected power plants. Of large concern to these power plants is not only the compliance with 316(b) but the overall financial affect it will have on the power plants O&M. The new rule will require power plants to continuously operate Traveling Water Screens (TWS), whereas they are typically run off of pressure differential or on timers. The overall affect on the power plants O&M budget could be significant. Over the past several years, several different types of Modified TWS technology have been developed, specifically for improving fish mortality rates.

Hydrolox provides engineered polymer as opposed to steel screens. The claimed advantages are:

Daniel M. Cicero, Senior Industry Development Manager Power Group, Water & Process Services Division of Nalco Company, explained how power plants can reduce their environmental impact by using good water chemistry. This presentation discussed three cases where power plants achieved that balance between environmental impact and low-cost power. In one case, using water chemistry modeling allowed a power plant to reduce withdrawals from a stressed waterway. In another, changing water chemistry reduced the impact of the power plant on the local community. In a third, the ability to respond to changing water quality reduced water costs and demands on the local water supply.

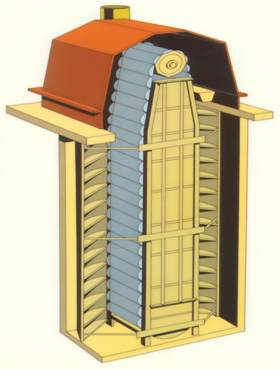

Trent T. Gathright, Sales & Marketing Manager Cooling Water Products at Ovivo USA, LLC Energy Group – Americas, briefly addressed different types of water intake screens and 316(b) alternatives. Numerous factors affect power plant cooling water at both once-through and closed cycle types. Various methods have been developed to deal with debris at both type power plants including indigenous debris, foreign blown in material and element disintegration. Pending 316(b) regulations may also affect how make-up water intakes are handled.

Ovivo developed the Dual Flow Conversion from existing technology that addresses virtually every aspect of screen reliability, operation and maintenance. This has been the driving force in the application of Dual Flow and Dual Flow Conversion Band Screens. With the dual flow the influent side is separated from effluent side. Debris carry over is completely eliminated.

Andrew Howell, Senior System Chemist for Xcel Energy, discussed several technologies that are available for condensing steam in power plants. Increasing difficulty with obtaining adequate cooling water supply for new generating units has required some power plant designs to use dry or hybrid (wet + dry) cooling systems. While necessary in some cases, these options have significant downsides that must be considered in planning for construction and operation.

Andrew reviewed the advantages and disadvantages of

Once through cooling is used where there are large water bodies and there is only a modest heat increase due to the discharge. Virtually no water is lost. Disadvantages are inlet fouling and the new 316 (b) regulations relative to fish entrainment. With recirculating cooling towers and 75 percent of the water is evaporated, there is cooling tower maintenance and issues relative to water discharges.

Dry cooling requires no water but the capital cost is high. Fan energy consumption is very significant. In hot weather the cooling capability is greatly reduced. Iron transport can be a major issue due to high surface area and air inleakage.

The hybrid system can operate in parallel with no isolation required. It does achieve full load in hot weather.

Bios, Abstracts and Photos can be seen at: BIOS, ABSTRACTS, PHOTOS - 5-23-13.htm

The individual presentations are as follows: