“Wet vs. Dry ESP” – Hot Topic Hour on Thursday, November 21, 2013

Steven A. (Steve) Jaasund, Manager Geoenergy Products for A. H. Lundberg Associates, presented “Wet ESPs for Improved Particulate Control.” Since the Clean Air Act was passed in 1970, there has been an unmistakable trend toward more restrictive emission control regulations. The present PM2.5 ambient air quality standards are just a stop along the way. Steve predicts more requirements will be expected. Until now, dry emission collection technologies have sufficed. However, the capability and the economic advantage of dry ESP systems are reaching limits and, in many cases, wet control technology may prove to be the better choice. This presentation outlined the advantages of wet control technology from both a performance and economic point of view.

Principal advantages of wet emission controls are:

Condensable Collection

o SO3 → H2SO4

o Organic vapor → liquid droplets

Gas Absorption Advantages

Insensitivity to Properties

Chemical makeup of particles is normally not a factor with wet scrubbers and wet ESPs.

Non-factors for wet systems

Very low emissions can be achieved burning a variety of fuels with SCR below 200.

Steve agreed with Bob McIlvaine that the concept of a wet scrubber capturing particulate and making calcium sulfite followed by a WESP would be a good choice for small utility and industrial boiler operators.

Paul Leanza, Senior Technical Engineer for Post Combustion Control Equipment with Pollution Control Services, Inc., discussed “Improving ESP Performance.” He focused on evaluating existing precipitators’ ability to meet the 0.030 lb/MMBtu regulations. The majority of existing ESPs are not operating under their original design basis and many existing ESPs have not been upgraded with modern operating philosophies or equipment. Taking a holistic approach in evaluating the precipitator in its current operating parameters permit a viable plan forward, as the operating parameters have been modified as additional post combustion control equipment like SO3, NOx, and Hg control have been incorporated over the last few years.

To achieve increased efficiency:

o Establishes foundation for all other improvements to be maximized

o Internal Inspection

· Review flow patterns on devices

· Record Data

o CFD and/or physical model study.

o Voltage and Voltage – Increase Voltage

o Mechanical Limitations

· Improve Clearances

· Increase Plate Spacing

o Electrical Limitations

· Improve Power Supply

· Improve Electrical Sectionalization

· Upgrade Discharge Electrodes

· Gas Conditioning in high resistivity cases.

o Reduce Excess Air

· Door Gaskets

· Casing Holes

· Duct Holes

o Review/Lower Gas Temperature

o Increase Length or Height

The introduction of mass emissions as a criterion for performance has raised lots of new issues and resolved others. The longer averaging time takes some of the pressure off short term spikes. On the other hand, emissions during exceedances or startup and shut down can add considerably to the total, If there is a scrubber, the mass emissions have to be measured downstream of the scrubber. Generally the scrubber further reduces particulate, so this can be taken into account. However, a CEMS which can operate in a wet stack is needed. Paul has not seen many good operating examples of wet stack CEMS.

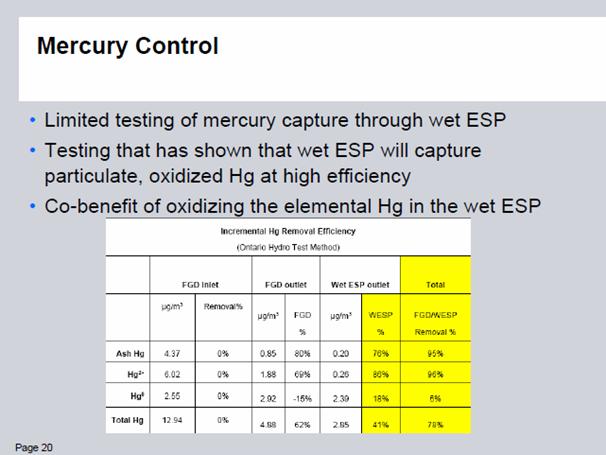

James "Buzz" Reynolds, Vice-President for Wet ESP Technology at Siemens Energy, Inc. Environmental Systems & Services, compared wet and dry ESP technology. While wet and dry ESPs retain similar high voltage and collection systems and share similar physical characteristics, many differences exist attributable mainly to the inherent design of the technology to address various size particles. Dry ESPs are used to capture coarse, filterable particulate matter (PM10) such as flyash. Wet ESPs capture sub-micron particulate matter, condensables and water mist commonly referred to as PM2.5. Where flyash characteristics play a large role in the sizing of dry ESPs, this is not the case with wet ESPs as they are not dependent upon particulate resistivity. Siemens has sold a number of systems to power plants which incorporate the wet ESP downstream of the scrubber.

The performance on mercury control is not completely predictable because of the numerous factors impacting performance but at the very least it is a co-benefit of using a WESP.

Bios, Abstracts and Photos can be seen at: BIOS, PHOTOS, ABSTRACTS - 11-21-13.htm

The individual presentations are as follows: