WELCOME

Weekly selected highlights in flow control, treatment and combustion from the

many McIlvaine publications.

Fabric Filter Market, Competitor Shares, IIoT, and TCO are Inseparable

There is no set of government or association statistics which provides fabric

filter media and element sales let alone future projections. The building blocks

to reasonable analysis are knowledge of the processes, knowledge of the total

cost of ownership (TCO) of filters for each process, and the aggregation of

sales by the individual participants. There is further iteration by comparing

the sales of media to the sales of the elements and to the inventory of

installed filters.

One venue with insights on market share and total cost of ownership was The

Filtration 2018 conference and exhibition last week in Philadelphia. The key

note address was by Michael Meis, Lead Research Specialist, 3M who described the

use of a blue tooth enabled pressure sensor on each Filtrete furnace filter. An

automatic purchasing program entails tracking of pressure by 3M and delivery of

new filters when needed. The result is direct marketing and elimination of

distribution discounts. The average fabric filter bag costs five times as much

as the average furnace filter. So you can expect to see remote bag monitoring

sooner rather than later.

When a company such as Arcelor Mittal which has centralized purchasing and buys

based on total cost of ownership is remotely monitoring and analyzing the

ownership cost of every bag, the sales environment will change significantly.

Filtration is an annual conference alternating between Philadelphia and Chicago.

(it was just announced that the schedule is now being changed to every 18 months

in Chicago). The event features

presentations and exhibitions by filter media suppliers as well as companies

selling components. There was a large display of filter fibers and media. The

filter element suppliers are visitors. Ten of the media exhibitors focused on

dust collection. The distinction between HVAC media and dust collector media is

that one handles light dust loads of ambient air while the other handles heavy

dust loads and therefore requires cleaning of the media.

|

Speakers and Media Exhibitors at

Filtration 2018 - Philadelphia |

|||||

|

Company |

Application |

||||

|

|

HVAC and Cabin Air |

Dust |

GT inlet |

Liquid Cartridge or

Macrofiltration |

Cleanroom HEPA |

|

Speeches |

|||||

|

Camfil |

x |

||||

|

3M |

x |

||||

|

Exhibitors |

|||||

|

Abalioglu |

x |

||||

|

Ahlstrom |

x |

x |

x |

x |

|

|

Baoji Jiaxin |

x |

x |

|||

|

Bondex |

x |

x |

|||

|

Central Alliance |

x |

||||

|

Dongguan Retop |

x |

x |

x |

||

|

Hezhong |

x |

x |

x |

||

|

H&V |

x |

x |

x |

x |

x |

|

Lenzing |

x |

x |

|||

|

Low & Bonar |

x |

||||

|

Lydall |

x |

x |

x |

x |

x |

|

NITTO |

x |

x |

x |

x |

x |

|

NXTNANO |

x |

x |

x |

||

|

Sandler |

x |

x |

|||

|

Shandong Taipeng |

x |

x |

|||

|

Shanghai Lingqiao |

x |

x |

x |

||

|

Shenzhen China Textile |

x |

x |

|||

|

Tex Tech |

x |

x |

|||

|

TTG |

x |

x |

|||

|

Wenzhou |

x |

x |

|||

Bondex, an Andrew Industries company,

introduced Hydrolox®, a new technology to the industrial filtration

market. It is produced from a unique process technology designed for better

filtration performance and lower operating costs. This product is currently in

operation in power utilities, agricultural, cement, mining, and asphalt

filtration applications.

Lydall is a major supplier of non-woven media for fabric filters.

Nitto displayed dust collector media composed of various base materials such as

woven fabrics and felt laminated with PTFE in a 2-layer structure; used in

filter bags for high collection efficiency at factories and incineration

facilities.

NXTNANO

nMAX medias feature a gradient density & diameter nanofiber matrix which can

deliver dust holding capacity in excess of 300% greater than standard nanofiber

with no appreciable change in pressure drop. With their proprietary HYPR

Spinning process NXTNANO produces nMAX in a single pass and can incorporate the

technology on to most nonwoven medias used today including: Cellulose,

Cellulose/Poly Blends, Spunbonds, Wetlaid Synthetics, Hydro-Entangled, and

Felted Medias. nMAX can be employed in pulsed filtration applications while

maintaining excellent dust release properties.

Shanghai Lingqiao Environmental

HEPA displayed a HEPA class

pulsable high efficiency PTFE media specially designed for tough applications

including plasma cutting, laser cutting, heavy dust loading, pharmaceuticals and

industrial welding.

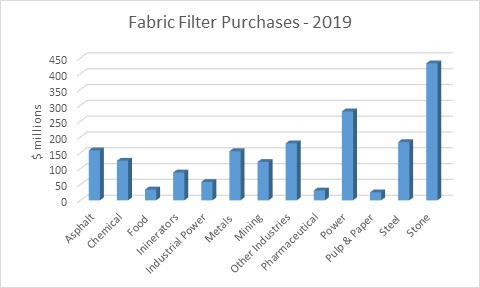

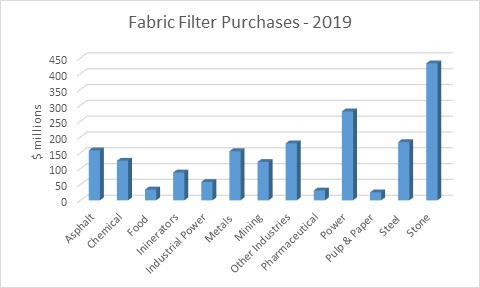

The world fabric media market in 2019 will be $1.8 billion.

The power industry and specifically coal fired generating companies will

be the top purchasers.

More details on the media, elements, filters and systems are found at

N021 World Fabric Filter and Element Market

Bob McIlvaine can answer your questions at rmcilvaine@mcilvainecompany.com 847-784-0012

ext. 112.

Track the Clean Industry Projects on a Monthly Basis

Cleanroom Projects provides details of cleanroom projects in each industry. The

database is supplemented by newsletters for each industry.

Here are the titles in the pharmaceutical project newsletter for one

month.

UNITED STATES

Evonik Expands Manufacturing Capacity in US and Canada

Novacap to Expand Pharmaceutical Offering

Alta View Specialty Clinic, Sandy, Utah

Vertex Opens Expanded Research Site in San Diego

Aldevron GMP Plasmid Manufacturing Facility, Fargo, North Dakota

Fresenius Kabi’s Pharmaceutical Manufacturing Facility Expansion, Melrose Park,

Illinois

Thermo Fisher Opens U.S. Precision Medicine Science Center

Wuxi Biologics to Launch in US

Eisai to Launch Center for Genetics Guided Dementia Discovery

Q Laboratories Opens New Lab Facility

LSNE Announces Acquisition of PSC Biotech’s Parenteral Manufacturing Facility

Thermo Fisher Invests in Biologics Footprint

Mayne Pharma Opens Oral Solid Dose Facility

REST OF WORLD

Telstar Wins Baccinex Design and Build Contract

Cherwell Laboratories Completes Transition to ISO9001:2015

Tudertechnica Builds Cleanroom for Silicone Hose

Sanofi Expands R&D in China with Chengdu Hub

Tot Biopharm Launches Mab Manufacturing Plant in China

Boehringer Ingelheim Consolidates with Biologics Centre

Umicore API Facility Passes cGMP Audit

CellGenix Expands Germany HQ

Wuxi Biologics Expands with ADC Build in China

Investment in Scotland to Strengthen the UK’s Place in the Global Pharma

Industry

Carleton University Health Sciences Building, Ottawa, Ontario, Canada

Juniper Pharma Services Expands Lab Facilities

Jansen Group Completes Interior Of Ultramodern Belgium Hospital

Zoetis’ Animal Vaccine Research and Manufacturing Complex, Suzhou

Samsung BioLogics’ Third Manufacturing Facility, Songdo

Cambrex Expands in Italy and Sweden

Cambrex Expands Generic API R&D Capabilities

Parker Details Investment Timeline, Launches New Single-Use System

Wasdell Group Invests in New Microbiological and Analytical Lab

More on Cambrex New Lab Expansion

Avara Pharmaceutical Services Acquires Major Sterile Manufacturing Facility and

Development Center in Canada

While the focus is cleanrooms, the project report is equally valuable for any

company selling into the semiconductor, pharmaceutical or other clean

industries. It is very valuable for

replace and retrofit opportunities since it retains data on plants installed

over the last 20 years.

For more information on Cleanroom Projects click on

80A World

Cleanroom Projects