Asian Ultrapure Water Sales to Exceed $3 Billion in 2015

In the rapidly growing Asian market, sales of ultrapure water systems and consumables will exceed $3 billion for the first time ever in 2015. This is the conclusion reached in the McIlvaine on line report Ultrapure Water World Markets.

Industry Totals ($ Thousands)

|

Industry |

2015 |

|

Coal-Fired Power |

1,044,935 |

|

Electronics |

993,932 |

|

Flat Panel |

662,483 |

|

Gas Turbines |

33,210 |

|

Industrial Power |

172,169 |

|

Other Industries |

79,009 |

|

Pharmaceutical |

138,426 |

Asia is building more new coal-fired power plants than the rest of the world combined. The majority of these power plants are of the ultrasupercritical design. These power plants need the highest purity boiler feedwater. Contrary to public perception, the Chinese fleet is operating more efficiently than the U.S. counterpart. The reason being that most of the Chinese plants have been built since 2000. By contrast, the average coal-fired power plant in the U.S. is more than forty years old. Asia has been quick to embrace newer technologies such as electrodeionization (EDI) as a substitute for ion exchange.

Asia is proceeding with come nuclear power plants. These power plants require the highest quality water. Combined cycle gas turbine plants also require high quality water but their needs per megawatt are less than half of that of a coal-fired power plant.

Over 50 percent of the market is attributable to the electronics and flat panel segment. Asia has more electronics facilities using ultrapure water than the other continents combined. One of the bigger growth segments in China has been photovoltaic cells for the solar industry. These plants do require ultrapure water although not as pure as required for semiconductor manufacture.

The one application where Asia does not dominate is pharmaceuticals. Water for injection (WFI) needs to be ultrapure because it is mixed with substances which are then injected into humans. The bulk of the manufacturing of pharmaceuticals is still in the U.S. and Europe.

Special instrumentation which can measure dissolved

oxygen and other constituents in parts per billion are required in ultrapure

water systems. There are a series of filtration steps ending in treatment by

reverse osmosis. Even after the water is ultrapure there is a concern about

re-contamination in pumps and piping. Consequently, in a semiconductor plant,

the water leaving the RO system passes through piping and then into an end point

membrane cartridge filter before being used to wash the wafer.

For more information on Ultrapure Water World Markets:

Cross-flow Membrane Market Revenues in 2014 will exceed $10.4 Billion

Sales of cross-flow membranes and equipment will exceed $10.4 billion in 2014, according to the latest projections in RO, UF, MF World Market published by the McIlvaine Company.

($ Millions)

|

Industry |

2014 |

|

Chemical |

435 |

|

Desalination |

3,166 |

|

Food |

273 |

|

Metals |

358 |

|

Mining |

120 |

|

Oil & Gas |

124 |

|

Other Industries |

744 |

|

Pharmaceutical |

903 |

|

Power |

652 |

|

Pulp & Paper |

250 |

|

Refining |

120 |

|

Residential/Commercial |

727 |

|

Semiconductor |

253 |

|

Wastewater |

367 |

|

Water |

1,994 |

|

Total |

10,486 |

|

|

|

Desalination is the biggest segment and is growing at 11 percent per year compared to 6 percent for the industry in entirety. This growth rate is exclusive of inflation. The market in China is growing faster than in any other nation. China plans to more than triple its production to 2.2 million cubic meters a day by 2015. China is also the largest purchaser of cross-flow membranes for the power industry. The boiler feedwater must be ultrapure.

Reverse osmosis is utilized in desalination, boiler feedwater, injectable pharmaceutical fluids and for purification of wastewater for reuse. Ultrafiltration is used for purification of water and wastewater and separation of products in the food and beverage industry. Microfiltration is edging out granular media filters as a method for purifying water for drinking purposes. A process for combining membrane filtration and biological treatment in one vessel is being widely used. Membrane bioreactors (MBR) are used to purify wastewater where the distance to the city wastewater treatment plant is high.

A further use of membrane technology is in sewer mining. A golf course can extract sewage from the pipeline and process it in a cross-flow membrane system. The product is then used to water the golf course while the reject is returned to the sewer line. The biotechnology industry uses microfiltration to separate products.

For more information on RO, UF, MF World Market, click on:

http://home.mcilvainecompany.com/index.php/component/content/article?id=71#n020

Thousands of Projects Worth Hundreds of $ Billions in Booming Oil and Gas Industry

Depending on the definition, the number of opportunities in the oil and gas sector ranges from a few thousand to over one million. At the top end there are single projects where the investment will exceed $10 billion. This is the conclusion reached in Oil, Gas, Shale and Refining Markets and Projects published by the McIlvaine Company.

|

Segment |

Number |

|

Operating gas and oil wells |

1,000,000 |

|

Well completions in 2012 |

105,000 |

|

Rigs in operation |

3,500 |

|

LNG trains in operation |

100 |

|

Current LNG projects |

20 |

|

Current operating large gas-to-liquids plants |

10 |

|

Large gas-to-liquids projects |

10 |

|

Smaller gas-to-liquids projects |

100 |

|

Liquid separation from natural gas projects |

200 |

|

Coal to chemical new projects |

50 |

|

Refineries in operation |

700 |

|

New refineries in planning and construction |

40 |

|

Refinery upgrades and environmental projects |

1,000 |

|

Tar sands expansion and new projects |

15 |

Existing gas and oil wells need pumps, valves, compressors, instrumentation and control equipment. Accuracy is needed due to the custody transfer and value of the products. Despite the large number of existing wells, the major capital investment is in a relatively small number of large projects.

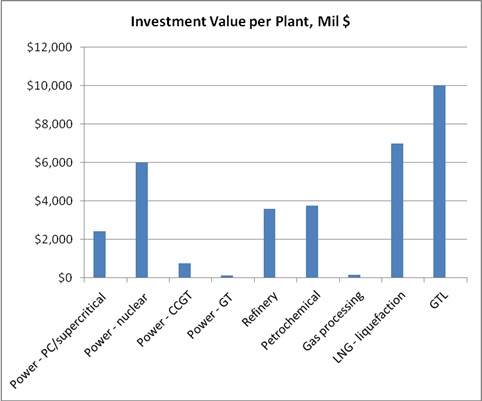

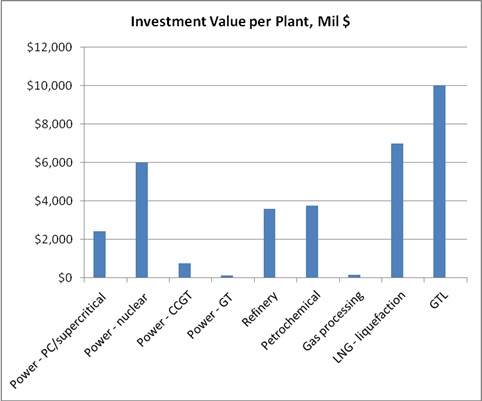

Figure 1: Comparative Investment Value (Overnight Cost) for major Industrial Plants

Some of the investments in the oil gas industry are even larger than the investment in a new supercritical coal-fired power plant. The gas-to-liquids plant now underway in Louisiana will cost Sasol more than $10 billion. New refineries, LNG and tars sands plants are all multibillion dollar expenditures. Much of this is for liquid and gas flow and treatment equipment. In addition, the tar sands plants have big investments in material handling.

With the shale gas and liquids boom there are many projects to separate liquids from gas. Conversion of coal to chemicals is attracting billions of dollars of investment. China is the leader with both direct and indirect gasification processes.

McIlvaine tracks the projects and provides market forecasts in Oil, Gas, Shale and Refining Markets and Projects. For more information on Oil, Gas, Shale and Refining Markets and Projects, click on:

http://home.mcilvainecompany.com/index.php/component/content/article?id=72#n049

----------

You can register for our free McIlvaine Newsletters at:

http://www.mcilvainecompany.com/brochures/Free_Newsletter_Registration_Form.htmBob McIlvaine

President

847 784 0012 ext 112

191 Waukegan Road Suite 208 | Northfield | IL 60093

Ph: 847-784-0012 | Fax; 847-784-0061