Important Pump Webinar Thursday on IIoT and Remote O&M

The Industrial Internet of Things (IIoT) will radically change the pump routes

to market and pump revenues. With a projected growth rate of 13 percent IIoT

will be responsible for pump revenues of $40 billion by 2030. The webinar on

Thursday, March 9 will explore this opportunity and provide recommended

strategies.

If general purpose pumps are the foot soldiers of IIoT, then high performance

pumps belong in the armored division. Their performance is much more critical to

the outcome of the battle to improve plant performance. IIoT promises to

revolutionize industry but only if it is accompanied by IIoW (Industrial

Internet of Wisdom). Decisive classification of high performance pump

applications, designs, and materials is critical to IIoT success.

Some pump companies are moving forward aggressively in this space. One is KSB

IIoT will generate continuous performance and condition information about each

pump. A large plant could have 5000 pumps. In order to determine which pumps are

working better than others it is necessary to divide the applications and pump

types into meaningful groups. One can then compare the performance of pumps from

different manufacturers in the defined group. McIlvaine has IIoW programs to

empower IIoT.

The market share for a specific supplier will be shaped by not only the quality

of his smart high performance pump but his willingness to assume a greater role.

At the very least he should develop his own remote monitoring center and provide

analytics and wisdom.

At the very minimum the pump supplier has to design his pump for smart sensing.

He also should supply the sensors. At level one he can sell to suppliers of

processes. But by teaming up with Honeywell, Rockwell, ABB, Schneider Electric,

Yokogawa or other stack 2 & 3 providers, the pump supplier can play a more

important role. The insights he will receive will allow him to improve his

products for specific applications.

For pump manufacturers, the IIoT opportunity is transformational. The path

forward is uncertain and will likely be continually revised. Pump suppliers

should further their IIoW efforts to make pumps smarter and should expand into

remote communications of this intelligence. They also should take advantage of

the IIoW potential. To learn more about this we invite you to join us at 10:00

AM CST on Thursday, March 9. To register click on

Weekly IIoT Webinars

IIoT and FGD Control: The

Opportunity and the Challenge

The industrial internet of things (IIoT) combined with remote operations and

maintenance promise to make the reduction of SO2 from power plants

much more cost effective. Flue gas desulfurization systems are costly to

operate. The reagent consumption can be as high as 4 percent of the total coal

consumption. The fans and pumps consume several percent of the plant's

electrical output. Large wastewater treatment systems separate gypsum, flyash

and toxic metals. Due to tough emission limits around the world the performance

of the FGD system is essential to operation.

Most of the new FGD systems are being built in countries without the mechanical

and chemical engineering FGD experience which has accumulated over decades in

the U.S., Europe, and Japan. With cost effective sensors and wireless technology

this experience can be utilized throughout the world.

IIoT is already being modestly applied to coal-fired power plants. With new open

platform cloud-based programs, a number of separate initiatives can be

integrated and leveraged.

Luminant and Duke Energy already have remote centers monitoring the rotating

parts at all their plants. Lhoist is monitoring liquid lime levels and

controlling reagent inventory in wastewater applications. Monitor Technologies

has radar-based level measurement for remote monitoring of bulk lime and

limestone levels as well as flow measurement for pneumatic conveying of

reagents. Thermo Fisher has a remote center monitoring the SO2 and

other emissions. Nalco has a remote center operating day and night to monitor

water quality.

MHPS has a remote center in the Philippines and is expanding into monitoring of

combustion in coal-fired power plants. Flowserve has remote monitoring of valves

and pumps. Howden has remote monitoring of fan and compressor operations. These

systems can reduce the cost of SO2 control maintenance by being

proactive as opposed to predictive or reactive. Several companies offer remote

monitoring of coal flow and ensure that the correct weight (not volume) is

introduced into the boiler.

With new open access platforms and the cloud, it is now possible for operators

and their suppliers to view all the relevant information at any location.

Furthermore, impacts on the balance-of-plant can be constantly included in the

decision making with inclusion of other centers such as the one created by Nalco

to measure water quality impacts.

The integration of this information for the plant operator is only the first

step. Remote monitoring will enable remote operations and maintenance. This

means that a plant in a developing country can be operated with the same

expertise as one in a country steeped in FGD control experience. Uniper (the

large German utility) and India Power have a joint venture to provide O&M

services to Indian power plants. Luminant is offering to use its remote center

to provide monitoring activities for industrial plants in Texas and other areas.

The cost of sensors is falling while the ability to measure critical parameters

is expanding. Wireless telemetry makes possible communication of vast amounts of

information at low cost. So how does the FGD industry take advantage of this

opportunity. The answer lies in climbing the pyramid.

Emerson calls the decision pyramid DIKW. At the bottom, you have data. Next is

information, followed by knowledge. At the top is wisdom. Here is how that

pyramid can be applied to FGD.

|

|

Means |

Parameter |

|

Data |

Sensors, Instruments, Wireless

Telemetry |

Vibration, temperature,

pressure, SO2, HCl,

pH, Hg. |

|

Information |

Historian, Edge Computing,

Permitted NOx and NH3

Emissions |

Flow of coal, reagent, flue gas,

air emissions |

|

Knowledge |

Data Analytics |

Empirical knowledge of the

unexpected such as scaling,

chloride saturation, mist

carryover. |

|

Wisdom |

Remote Monitoring, Subject

Matter Expertise, Knowledge

Systems |

Upgrading pumps, and valves,

changing operations to meet new

regulations, adjusting to

reagent price changes |

Worldwide companies such as Lhoist and Lafarge are well positioned to lead the

way. Lafarge has digital services in many developing countries to help small

calcium products sellers inventory their goods. They also have IIoT experience

at their plants. They have teamed with Schneider Electric at their

Dujiangyan cement plant in China which has three cement lines with a production

capacity of over 5 million metric tons per year. The IIoT program has provided:

·

Kiln operation optimization

·

Monitoring clinker over-burning

·

Over-cooling improvements in the cement finish grinding operation

·

Maximizing efficiencies in the operating hours within cement mills

·

Air compressor optimization, with a centralized control system avoiding idle

running of air compressors

·

Enhancements in crew performance with "Kiln Coach Report"

·

A project payback period of two years

·

Valuable energy improvements by reducing power consumption by 0.8kWh/t cement

·

Production cost and CO2 emissions have been reduced

·

Remote access of the system also facilitates technical support when required, as

well as access for ongoing energy analysis consulting and support.

The success of IIoT and Remote O&M for FGD and other coal-fired power plant

operations will be greatly enhanced by capturing the experience of other

industries and forming collaborative ventures with large numbers of suppliers.

McIlvaine has both the technical and market decision systems to aid these

groups.

The market opportunities for IIoT are analyzed in

N031

Industrial IoT and Remote O&M

The FGD market opportunities are analyzed in

N027 FGD Market and Strategies

Knowledge support is provided in

44I Coal-fired Power Plant Decisions

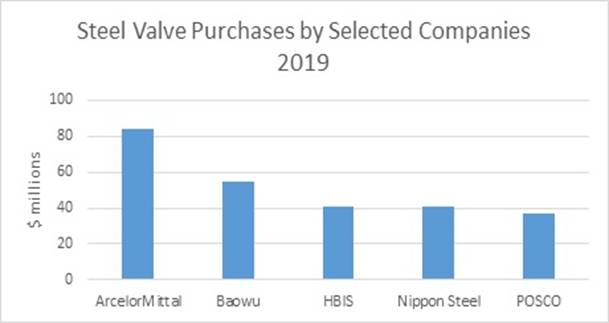

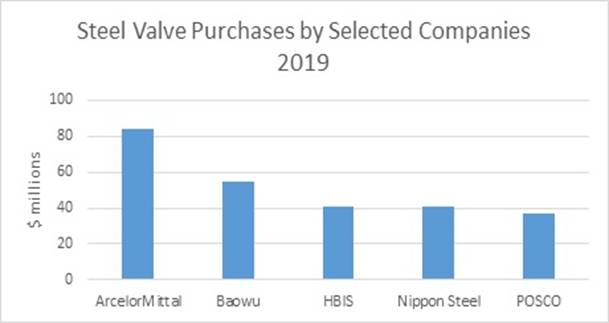

The Role of High Performance Valves in IIoT

The Industrial Internet of Things (IIoT) will radically change the valve routes

to market and valve revenues. With a projected growth rate of 13 percent IIoT

will be responsible for valve revenues of $50 billion by 2030. (1)

If general purpose valves are the foot soldiers of IIoT then high performance

valves belong in the armored division. Their performance is much more critical

to the outcome of the battle to improve plant performance. IIoT promises to

revolutionize industry but only if it is accompanied by IIoW (Industrial

Internet of Wisdom). Decisive classification of high performance valve

applications, designs, and materials is critical to IIoT success.

IIoT will generate continuous performance and condition information about each

valve. A large plant could have 10,000 valves. In order to determine which

valves are working best it is necessary to divide the applications and valve

types into meaningful groups. One can then compare the performance of valves

from different manufacturers in the defined group.

A high-performance valve is one which is in any of following three types of

service.

·

Severe Service: Corrosion, pressure, temperature, process operating

fluctuations are all conditions that qualify an application as severe service.

·

Critical Service: Safety, product purity, continuous operation, and

product toxicity are criteria of critical service.

·

Unique Service: The distinction is often made between an engineered valve

versus an off the shelf or standard valve. In any case, the decision making for

unique service valves needs to be made with prioritization of the lowest total

cost of ownership.

|

World Industrial Valve Revenues

- 2030

($ Billions) |

|||

|

Revenue Source |

Total |

General Performance |

High Performance |

|

Total

|

90 |

40 |

50 |

|

Old route to market |

40 |

18 |

22 |

|

New route to market |

30 |

13 |

17 |

|

Additional Revenue |

20 |

9 |

11 |

|

Revenues attributable to IIoT

and Remote O&M |

50 |

22 |

28 |

High performance valve sales of $17 billion in 2030 will be made to third

parties. The IIoT additions to the valve offerings will boost revenues by $11

billion. As a result, the high performance IIoT valve market will be $28

billion.

The market share for a specific supplier will be shaped by not only the quality

of his smart high performance valve but his willingness to assume a greater

role. At the very least he should develop his own remote monitoring center and

provide analytics and wisdom at higher levels. The levels as defined by

Honeywell are shown in the chart below.

|

Level |

Device |

Function |

|

1 |

Smart Sensors |

Sensor and actuator with no or

small amount of local processing

and data storage |

|

2 |

Edge Device/Smarter Connected

Sensor |

Includes a sensor, some local

processing, data storage, power

management, connectivity,

security and user interface |

|

3 |

Local System/Connected Edge |

Connect to a gateway, controller

or server. Connectivity is

mostly local in a closed loop

system, could have cloud

connectivity. |

|

4 |

Cloud Infrastructure |

Allows data to be accessed,

aggregated, stored monitored and

actuated anywhere in the world |

|

5 |

Big Data Analytics |

Servers with cloud connectivity

gather data for advance

applications e.g. data

analytics, visualization,

machine learning |

There is also a scope hierarchy which influences potential IIoT. Valve suppliers

can seize the opportunity to expand their scope by offering Level 3 programs.

|

Hierarchy |

Deliverable |

Level |

|

1 |

Flow control component products

such as valves and pumps |

1-3 |

|

2 |

Processes e.g. separation,

reaction, heat transfer,

combustion |

1-4 |

|

3. |

Systems e.g. ultrapure water

steam generation, wastewater

treatment |

1-5 |

|

4 |

Plants e.g. refineries, power

plants, pharmaceutical,

semiconductor |

1-5 |

A large valve supplier, e.g. Pentair or a valve supplier with automation

divisions, e.g. Metso and Flowserve, a valve supplier which is part of a company

also selling processes, systems and or plants, e.g. GE, Wärtsilä, has the

opportunity is to be a Level 5 provider.

At the very minimum the valve supplier has to design his valve for smart

sensing. He also should supply the sensors. At Level 1 he can sell to suppliers

of processes. But by teaming up with Honeywell, Rockwell, ABB, Schneider

Electric, Yokogawa or other Level 2 & 3 providers, the valve supplier can play a

more important role. The insights he will receive will allow him to improve his

valve products for specific applications.

The valve supplier can better improve his products with the support of what are

called "subject matter experts" of the IIoT community. It can be argued that

subject matter expertise needs the same degree of organization (IIoW) as IIoT.

One example of this is a series of Decision Guides on specific high performance

valve applications which is being assembled by McIlvaine.

Three of the most challenging applications for valves in the oil and gas

industry are molecular sieve switching, flow control in oil and gas drilling,

and gate valves used at greater than 5000 psi. When switching from one

dehydration sieve unit to another zeolite particles are entrapped in the gas

stream and create valve problems. The choke valves used for control in drilling

are subjected to sand and other abrasive particles. In addition, the

temperatures and pressures can be high. Gate valves used in hydraulic fracking

and subsea operations at pressures greater than 5000 psi are operating in a

tough environment where selection of the right designs and materials is

critical.

In the power industry most new coal-fired boilers are operating in the

ultra-supercritical range, so valves are typically subjected to temperatures

above 750°F. These plants are quite large (up to 1000 MW), so any downtime is

quite costly. Heat recovery steam generators used with gas turbine plants are

often required to stop and start hundreds of times during the year. This rapid

cycling is encountered where gas turbines are providing the backup power to

solar and wind. This cycling has created a unique flow acceleration corrosion

(FAC) problem. Decision Guides are being continually expanded in these four

areas and will serve as an example of what can be done to further valve IIoW.

(3)

For valve manufacturers the IIoT opportunity is transformational. The path

forward is uncertain and is likely to be continually revised. Valve suppliers

should further their IIoW efforts to make valves smarter and should expand into

remote communications of this intelligence. They also should take advantage of

the IIoW potential. High performance valves should be given the highest

priority.

(1)

For more information click here:

Industrial IoT and Remote O&M

(2)

For more information click here:

Industrial Valves: World Market

Bob McIlvaine

President

847-784-0012 ext. 112

rmcilvaine@mcilvainecompany.com

www.mcilvainecompany.com