Improving Limestone Scrubber Efficiency - True

Cost Investigation

Sessions:

Cycling Load, Dual Fuel Firing, and

Understanding Operating and Maintenance Savings

for Air Quality Control Systems

will be presented by Suzette Puski, Business

Development Manager,

Babcock Power Environment. This company

has a partner and its first wet FGD order in

India.

Exhibitors:

AECOM

has

a license from

Linde

to use ozone to capture NOx in FGD

scrubbers.

Boldrocchi supplies DSI systems.

Burns

& McDonnell participated in the India

SOx-NOx conference.

CECO

supplies FGD dampers.

Duechting supplies FGD pumps.

Emerson provides slurry level control

and automation.

Hamon

provides FGD systems.

Haynes provides alloys for scrubber

vessels and components.

Howden provides FGD exhaust fans and

oxidation blowers.

Southern Environmental supplies dry

scrubber systems.

Teledeyne Monitor Labs supplies FGD CEMS

as does

Thermo Fisher.

Wood has acquired the

Wheelabrator APC and wet FGD systems.

WSP

is a worldwide consultant on power plant

systems. We will be continually updating the

following

directory of attendees, exhibitors and

speakers who are interested in discussing dry

and wet FGD.

Issues to be discussed:

·

Limestone forced oxidation with gypsum vs. lime

natural oxidation and chemical fixation

·

Oxidation blower options

·

FGD recycle Pump True Costs (see separate

analysis)

·

Slurry level control for calcium sulfite

·

FGD chemistry and

emission control

·

Vacuum filter belts and filter options

U.S. and Indian FGD operators both are

interested in higher SO2 removal efficiency. In

the case of U.S. operators faced with operating

higher cost old plants the potential to cut pump

connected horsepower is appealing.

For Indian operators there is the

potential to reduce capital as well as operating

costs. Three options involve scrubber design.

scrubber chemicals, and optimization systems.

Relative to scrubber design there are the

following choices

-

A spray tower with

liquid flows as high as 100

gpm/1000 cfm and pressure loss

of 3-6” w.g

(MET, Doosan, and many

others)

-

A modified spray tower (MHPS)

-

A tray or rod deck scrubber with

flows less than 50

gpm/1000 cfm and pressure loss

of 6-8” “ w.g. (B&W)

-

A sump scrubber with no liquid

flow and pressure loss of 9-11”

w.g

Where there is enough fan capacity a tray or rod

deck can be added in a spray tower to increase

efficiency.

Another alternative is to use dibasic acid or

another chemical to enhance scrubber efficiency.

Some plants in Europe add lime during

periods when higher efficiency is needed.

India is moving forward with approximately

100,000 MW of FGD systems.

This will require 15-20

million of tons of limestone per year.

SHI-FW has conducted a study which shows

that because of the poor limestone a CFB

scrubber is the best choice for many plants

https://www.shi-fw.com/wp-content/uploads/2019/10/Show-me-the-money-SHI-FW-CFB-Boiler-Economics-Modern-Power-Systems.pdf

This analysis is based on a 300 MW plant with

0.6% sulfur. Limestone cost is 7 rs Crore /yr

($989,000) based on 5 tons per hour and a cost

of limestone at

1750 rs./ton ($ 24.50/ton) vs EPA cost

estimates based on $30/ton. The tons/MW = 134.7.

Scrubber additives can improve the economics

when using a poor quality limestone. One answer

is that if treatment chemicals

can be justified for a 0.6% sulfur coal,

they will be even more attractive for higher

sulfur coals.

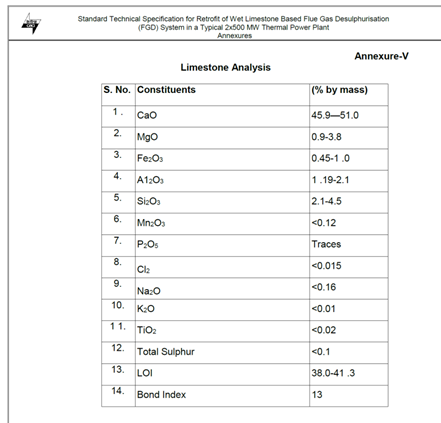

Here is the CEA specification for Indian

Limestone.

Brad Buecker of Chemtreat has reviewed this

analysis and concludes

“With regard to the analysis, the CaO

range equates to a calcium carbonate (CaCO3)

range of 82 to 91 percent. A quick thought

suggests that this might be an excellent

application for ChemTreat’s DBA replacement

product. A general rule-of-thumb that I always

followed is that limestones with 94% or greater

CaCO3 concentration are usually quite

reactive (if ground properly). My gut

feeling says that the stones outlined in the

analysis could be significantly enhanced in

reactivity using our FGD1105 product.”

Brad wrote an article in

Power

Engineering earlier this month where he

provided further details: “Many plants do not

have access to such high-purity limestones. The

stone may contain a significant concentration of

dolomite (MgCO3∙CaCO3)

or inert materials that inhibit

reactivity. Thus, supplemental methods are

needed to boost the reactions. A common

method that has been used for years is addition

of dibasic acid (DBA) to scrubber process

streams, but new technology is improving upon

this chemistry. Dibasic acid is a generic

name for a blend of relatively short-chain

dicarboxylic acids (two COOH functional groups),

which add hydrogen ions (H+)

to help in the dissociation of limestone, and

then circulates through the process to continue

assisting with SO2-absorption

chemistry. However, the availability,

cost, and even efficiency of DBA have placed

limits on the chemical’s effectiveness. An

alternative is available that is much more

promising for wet FGD reactivity enhancement.”

Personnel at the Longview Power Plant in

Maidsville, West Virginia had faced constant

problems with handling and feeding DBA to the

wet-limestone scrubber of their 770 MW

supercritical steam generator. For

example, the product must be kept warm to

prevent solidification. Exacerbating the

issues were DBA delivery constraints, both from

a distance perspective and that the tank volume

had to be lowered to less than 10% before

introduction of a fresh load. Combined,

these factors affected scrubbing efficiency and

SO2 removal, the latter of which is a

critical aspect of scrubber operation.

Violation of discharge permits can result in

load restrictions or forced shutdowns.

Accordingly, the plant staff began full-scale

testing and then subsequent application of an

alternative, specially-formulated organic acid

blend with the product name of FGD1105 (patent

pending). Almost immediately upon chemical

addition, SO2 emissions dropped by

approximately 35% to 40%, such that even at full

load one of the scrubber’s five recycle pumps

could be, and was, removed from service.

Stack SO2 emissions only slightly

increased from 120 lb/hr to 200 lb/hr following

the pump reduction. This action alone reduced

auxiliary power consumption by 3 MW, at a

projected annual benefit of

approximately

$700,000. As a test, the plant staff

removed a second recycle pump from service and

found that SO2

removal was still more efficient than in the

period prior to the FGD1105 addition.

According to Chad Hufnagel, Longview’s Plant

Manager, the ability to operate with 3 recycle

pumps instead of 4 or 5 has provided

additionally flexibility for recycle pump

maintenance strategy, as well as offering

additional net revenue opportunity with improved

unit efficiency.

Therefore the cost saving is more than

$700,000/yr less the cost of the additive. There

are other questions to pursue such as changes to

wastewater treatment costs. This analysis is

based on a spray tower.

If a tray tower or rod deck scrubber is

used then the saving would have to be in fan

rather than pump horsepower. Another question to

be answered is the parasitic cost of power for

the average Indian plant vs that in the U.S.

The McIlvaine

Coal

Fired Power Plant Decisions has a number of

relevant papers. They include

INVISTA DBA Dibasic Acid - The McIlvaine Company

www.mcilvainecompany.com/Decision_Tree/subscriber/Tree/DescriptionTextLinks/Richard...

There are a number of suppliers of DBA around

the world. They include

-

Cathay Industrial Biotech

-

Palmary Chemical

-

Henan Junheng Industrial

Group Biotechnolog

-

Evonik

-

Invista

-

Zibo Guangtong Chemical

FGD Scrubber Monitoring and Control:

The use of the right chemicals is only part of

the true cost reduction. Monitoring and control

of parameters is equally important. The CEMS

system should be used for process monitoring. In

the case above the system could operate with 3,

4, or 5 pumps depending on the reactivity of the

limestone. However varying sulfur levels in the

incoming coal provide another variable.

If SO2 is measured prior to the scrubber

as well as at the stack the right balance

between efficiency and energy consumption can be

determined.

The measurement of liquids is also important.

Brad Buecker addressed this subject in an older

Power

Engineering article.

He pointed out that it is important to

constantly measure the alkalinity in the

scrubber module or modules, as too much

alkalinity will waste reagent while lean

alkalinity will impair SO2

removal. The technique universally employed in

wet scrubbers is pH monitoring. These

measurements must be continuous, with control of

reagent feed rates based upon the readings. For

the lab staff, grab-sample pH analyses are very

important to make sure that the in-line

probes/monitors are accurate.

The slurry circulating pumps can only handle so

much mass before electrical requirements are

exceeded. Like pH, scrubbers are equipped with

continuous density monitors, typically utilizing

radioactive detectors. Again, the lab staff

needs to monitor density on a grab sample basis

to ensure the accuracy of the continuous

instruments.

Control of solids chemistry offers interesting

challenges and is extremely critical to

operation. Experience has shown that operation

in either a completely oxidized state (no

calcium sulfite-sulfate hemihydrate in the

scrubbing slurry) or a completely un-oxidized

state (no gypsum in the slurry) minimizes

scaling in the scrubber. Scale buildups can be

extremely problematic, as deposit formation on

scrubber internals and subsequent gas flow

restrictions may cause unit de-rates and even

forced outages if gas flow is severely

restricted.

The technique that has proven itself very well

for scrubber solids analysis is thermogravimetry.

A thermogravimetric analyzer (TGA) is a

quantitative not a qualitative instrument, so

the operator needs to have a good idea of the

primary constituents in the sample before

analysis. If the sample compounds decompose at

distinct and separate temperatures, it becomes

easy to calculate the concentration of the

original materials. Wet-limestone scrubber

byproducts lend themselves well to this

technique.

https://www.power-eng.com/2008/07/01/properly-monitor-your-scrubber-chemistry/

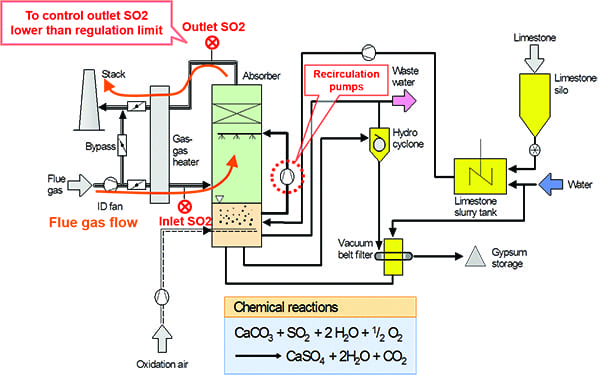

The plant can vary the number of pumps in

operation. An

optimization system enables the plant to

use the minimum number of pumps required to keep

the outlet SO2

lower than limits. This also reduces the amount

of limestone slurry required, but the major

contributor to cost savings is cutting energy

use by removing one or more recirculation pumps

from service based on the input SO2

value. One optimization system available was

described by

Toshihiko Fujii of

Yokogawa Electric Corp.

in a recent

Power

Magazine article.

FGD control is normally implemented by the

distributed control system through the

regulation of limestone slurry flow. The

limestone slurry flow is controlled based on the

pH value as measured by an analyzer installed in

the absorber. Typically, the pH value must be

controlled to ensure proper performance of the

desulfurization process in the absorber,

therefore the limestone slurry flow is

controlled to maintain the proper pH value. For

this control scheme, other indices such as the

FGD inlet and outlet SO2

are not used, and all recirculation pumps are

operated regardless of the inlet SO2

value, with slurry flow regulated by the control

valve.

The optimization system typically consists of

three functions: enhanced regulatory control,

model-based prediction, and process value

prediction. The system uses these three

functions to continuously determine the minimum

required number of recirculation pumps in

operation, and to calculate the setpoint for the

limestone slurry flow PID

(proportional-integral-derivative) control loop.

A 700-MW coal-fired power plant in Japan

implemented the optimization system. This plant

runs about 300 days per year at baseload and is

not in operation for the other 65 days of the

year. The energy savings realized by running

only the required number of recirculation pumps

was 12.4% of the unit’s total house load,

equating to about $900,000 in energy savings per

year based on market conditions in Japan.

Another benefit was reduced pump run times,

which resulted in lower pump maintenance costs

and extended pump life. A third benefit was less

limestone usage.

https://www.powermag.com/advanced-process-control-for-optimizing-flue-gas-desulfurization/?pagenum=1

Background Information in

FGD &DeNOx

Knowledge Network (Free To Power Plant

Operators)

There are thousands of relevant articles for

immediate retrieval.

You can click on specific aspects such as

DBA

2. DBA Increase

FGD Efficiency by Five Percent at AES Deepwater

... FGD

and DeNOx NEWSLETTER December 2004 No. 320 DBA Increase

FGD Efficiency by Five Percent at AES Deepwater

The use of organic diacids in wet limestone

scrubbers remarkably improves ...

3. DBA and

Mg Lime are Two Routes to 98 Percent SO2 Removal

... FGD

and DeNOx NEWSLETTER August 2006 No. 340 DBA and

Mg Lime are Two Routes to 98 Percent SO2 Removal

McIlvaine's "Hot Topic Hour" on July 13 ...

4. Pilot

Study Shows DBA Use

Impacts Biological Selenium Removal in FGD

Wastewater

... FGD

and DeNOx NEWSLETTER August 2008 No. 364 Pilot

Study Shows DBA Use

Impacts Biological Selenium Removal in FGD

Wastewater Staged biological treatment concepts

were developed by Enos Stover ...

\

5. Duke’s

Marshall Wet FGD is Up and Operating With Most

Goals Met

... .)

In the event of an unplanned spray pump outage,

organic acid (DBA)

will be injected into the system allowing the

required SO2 removal performance to be ...

There are 35 articles relevant to re-emissions

1. Nalco’s

Mer-Control 8034 Reduces Mercury Re-Emission from

Wet FGD Systems

... FGD

and DeNOx NEWSLETTER July 2012 No. 411 Nalco's

Mer-Control 8034 Reduces Mercury Re-Emission from

Wet FGD Systems Nalco's Mer-Control 8034 (a

poly-dithiocarbamate and a mercury chelating

compound ...

Terms matched: 1 - Score: 191 - 12

Jun 2018 - URL:

http://www.mcilvainecompany.com/fgddenox/subscriber/2012

2. Duke’s

Environmental Compliance Plan Includes SCR for

Cayuga 1, 2

... 535-MW

Unit 1 – SCR, DSI, ACI, arsenic mitigation

system, mercury re-emission chemical injection

system. 535-MW Unit 2 – SCR, DSI, ACI, arsenic ...

3. Over

90 Percent Hg Removal by Wet FGD and SCR at Mt.

Storm

... W

injects a liquid sodium hydrosulfide reagent

into the wet FGD slurry to eliminate

mercury re-emission. During the first phase of

testing, the focus was on analyzing the

potential ...

4. temp.htm