|

WELCOME

Weekly selected highlights in flow

control, treatment and combustion from the many McIlvaine publications.

· POWER-GEN

New Orleans Nov. 18-21 APC and Valve Tour Guides Updated

·

Market Research from Leonardo DaVinci to IIoW

· Indian

Valve Companies form an Association with Lots of Power Plant

Experience

· Coal

Gasification Conference Next Month in India

POWER-GEN New Orleans Nov. 18-21 APC and Valve Tour

Guides Updated

Power-Gen has a number of courses,

speeches and exhibits with useful information about air pollution control

and valves. Last week we published the following tour guides to assist

decision makers in their scheduling. This guide was updated this week and

will be continually updated until November 16 and the latest version will

be on display at http://www.mcilvainecompany.com/PowerGen_2019/Power-Gen_2019_Information.pdf

There are two purposes

·

Help suppliers with programs to pursue the

international market.

·

Help end users make lowest cost of ownership

decisions.

Helping suppliers pursue the international

market: McIlvaine and three other speakers will conduct a course for

suppliers on Monday afternoon on ways to pursue international

markets. One of the recommendations will be that suppliers analyze the

exhibition activity at Power-Gen Asia, Power-Gen India and other

exhibitions. The tour guides are a valuable resource for this purpose.

There is a guide on resources for air

pollution control and valves generally. But there are also some

special guides which include

·

Dry and Wet FGD Scrubbers

·

Electrostatic Precipitators Upgrades

·

Turbine Bypass Valves

·

Gas Turbine Inlet Filters

Market

Research from Leonardo DaVinci to IIoW

Market

research is treated as a peripheral management tool but due to the

abundance of available knowledge today, it can and should be used as the

foundation of business plans.

There

was a point in time when Leonardo DaVinci would have been the best market

researcher for anything to do with art, medical science, or military

engineering. However, the world’s

knowledge has been growing at exponential rates. Furthermore this knowledge

is easily accessible as part of the Industrial Internet of Wisdom (IIoW). Leonardo would be astounded to learn that

you can analyze employment at a competitor’s pump factory by using google

earth to count the cars in the parking lot; or that you can obtain a

detailed description of the equipment in that plant from publicly available

environmental and safety permits.

Market

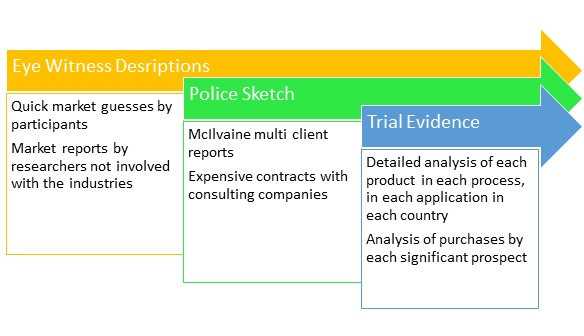

research in the combust, flow, treat industries can be likened to a

criminal investigation. You start with eye witness descriptions of the

perpetrator. Then you create a police sketch representing the knowledge

available. If this leads to an arrest, the next step is to prepare

comprehensive evidence.

Since

market research is typically considered to be a peripheral tool companies

are content with guesstimates by sales and management people or a top down

report by someone who is not familiar with the products and processes. This level of effort is similar to just

gathering eye witness descriptions.

When

higher accuracy is deemed appropriate a company may acquire a McIlvaine

multi-client report or an expensive study from one of the consulting firms.

This is common in mergers and acquisitions. McIlvaine reports each contain

as many as 50,000 forecasts for eight years for each product in each

industry in each of 80 countries and sub regions. This information is much more useful but

could be classified as a high quality police sketch.

If

market research is going to be the foundation of the business plan it

requires more detailed information and the input of subject matter

ultra-experts. The typical McIlvaine multi-client reports have forecasts for each of 80

countries and regions segmented into 13

industries.

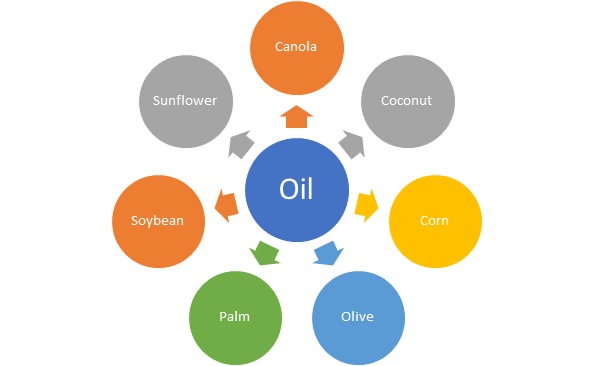

Food

can be further segmented.

The

food oil segment can be then be segmented by oil type. This is quite important

since palm oil and soybean oil are produced in different areas with unique

processes.

Forecasts

of purchases by companies comprising 70 percent or more of the market are

provided with the multi-client reports.

This would include companies such as Cargill and ConAgra which are

among the ten largest food industry purchasers of combust, flow, and treat

products.

In

the multi-client report forecasts are supplied for the two largest food oil

producers among a total of ten food producers and 100 total purchasers of

combust, flow and treat products.

In

a further customized multi-client report just on the food industry, there

would be ten food oil companies analyzed among 100 food companies. A further custom analysis of food oil

companies would provide forecasts for 250 producers.

If

this level of analysis is pursued for each industry, forecasts are produced

for several thousand companies comprising 90 percent of the purchases for

most industries. This is because 99 percent of the purchases are made by

companies which already utilize the type of product being analyzed. This is not true in lithium recovery,

biopharmaceuticals, and manufactured frac sands where there are many new

entries. However this new group

represents less than 3 percent of the total market.

The

approach does also not

adequately cover industry segments

which are going to be driven by new technology or regulations. However, McIlvaine is involved with the

new technology in many areas including recommending specific pursuits such

as

Biomass

Ready Coal Fired Plants and Massive Tree Planting will be the Compromise

Climate Change Solution

The

Future of Biopharmaceuticals will Depend on Perceived Value vs Cost

Join

the Debate on Insitu Rare Earth Recovery

McIlvaine

is also involved in those areas of the world where the most combust, flow

and treat expansion is taking place.

India

will be a Major Purchaser of Dry Scrubbers

This

detailed market research makes sales leads obsolete and provides the basis

for collaboration.

Would

You Rather Share Sales Leads with Your Allies or with Your Competitors?

More

information on the multi-client market reports is found at www.mcilvainecompany.com

and then click on markets.

Bob

McIlvaine can answer your questions at rmcilvaine@mcilvainecompany.com direct

847 784 0013 cell 847 226 2391

Indian Valve Companies form an Association with lots

of Power Plant Experience

The Indian Valve and Actuator Manufacturers Association (IVAMA)

was formed this year to support the betterment of the

Indian Valve Industry. The objective of IVAMA is to be the “Voice of the

Industry” to facilitate Growth Opportunities for its members and be a

gateway to the Global Valve Community. IVAMA

will offer its members an array of services ranging from Education & Training,

Networking Opportunities, Access to Market Information, and Updates on

Projects, Policy Advocacy & Conferences. IVAMA

will work closely with Government agencies influencing policy framework.

IVAMA will be a platform to

enhance business and develop newer markets by interacting with other Member

Industries, Global Businesses, State & Central Governments. It will

organize specialized conferences to nurture capabilities and sustain

competencies in the Indian Valve Industry.

The McIlvaine Company has

already been working with the group and with Mission Energy to explore opportunities for working with

the Indian power producers. Here are some of the members and their

activities in Power.

Advance Valves, Noida Uttar Pradesh

Advance has a wide range of

valves to meet the requirements of the Power sector. It offers

a double-eccentric design for butterfly valves for

CW, FW & DM Water applications, and the high-performance Triple

eccentric Butterfly valves for Steam-based and high-pressure applications.

Dual plate check valves are a superior NRV option as compared to the

swing-check valve.

The Triple Eccentric valve has an intrinsic

fire-safe design, which makes it suitable for numerous applications,

including steam-based applications where temperatures are in excess of 750

deg C. In fact, this valve can replace the bulkier Gate Valve as well, in

certain applications. Advance has recently

supplied an 1800 mm Metal-Seated Triple Eccentric

Butterfly to Bhushan Power Plant in Orissa. Clients in this sector include

NTPC, BHEL, NPCIL, Bhushan Power, Alstom Power, Jindal Power, Larsen &

Toubro, Tata Power, MSEB, BSES and many others, including those who have

developed their own captive power plants.

AUMA, Bangalore Karnataka

AUMA recently supplied nearly

2300 actuators for six large coal-fired power plants being built

by NTPC, AUMA India provided 500 actuators for each of

the three plants at Lara, in Chhattisgarh; Barh in Bihar and

Gadarwara in Madhya Pradesh. Another 484 actuators were delivered to Malwa,

also in Madhya Pradesh, 306 to two smaller projects at Meja in Uttar

Pradesh and Solapur in Maharashtra.

The six projects range in size from 2 x

660 MW to 5 x 800 MW and all except the Lara plant are

supercritical. The actuators are deployed for intelligent valve control

across all processes within the plants, including feedwater treatment,

steam generation, combustion air control, turbine control, flue gas

management, and cooling water supply.

GM, Metoda Gujarat

The company was founded in 1986 and is a

diversified valve manufacturer serving the nuclear power, oil, gas,

fertilizer and certain other industries. Clients include BHEL, Andhra

Pradesh State Electricity, and Gujarat State Electricity.

Kitz, Maharashtra

Trunnion-mounted ball valves are supplied to

the power industry by distributors including Concorde Valves in

Mumbai.

L&T Valves, Chennai Tamal Nadu

L&T Power offers

turnkey solutions for both coal- and gas-based power plants in addition to

valves. Earlier this month the Power business

of Larsen & Toubro (L&T) had successfully placed into operation two

thermal power units of 660 MW each at NTPC’s Khargone Super Thermal Power

Project in Madhya Pradesh and Tanda Thermal Power Station in Uttar Pradesh.

This has enabled NTPC to add 1320 MW capacity to the national grid and has

also demonstrated L&T’s capabilities in executing complex power

projects in the country.

The 660 MW Khargone unit is the country’s

first ultra-supercritical unit set up on a complete engineering,

procurement and construction (EPC) basis. Ultra-supercritical units feature

steam parameters of 600 degree Celsius and 270 kg/cm2 pressure resulting

into higher efficiencies, enabling plants to consume less coal resulting in

lesser emissions in comparison to sub-critical and supercritical power

plants. The 660 MW Tanda unit is equipped with a supercritical boiler

manufactured by L&T-MHPS Boilers Pvt Ltd, a joint venture company of

L&T and Mitsubishi Hitachi Power Systems (MHPS), Japan. The Khargone

and Tanda projects are each of 2x660 MW capacity.

Microfinish, Hubli Karnataka

Established in 1971,

Microfinish group is a manufacturer of ball valves, bellows

sealed globe valves, process pumps, gate globe and check valves, pneumatic

actuator and automated units. Microfinish products can be found in

many power plants installations. Valves are used in fuel lines, HP and LP

steam, condensate, hot gas, flue gas, fly ash as well as utilities such as

cooling water and compressed air. The Microfinish knifegate valves

are included in the following article. https://www.valve-world.net/pdf/Knife_gate_and_slurry_valves_Part2.pdf

Oswal Kalol, Gujarat

The company can produce 36,000 valves per

year at its 110,000 m2 facility. It has a steel foundry making alloy

castings. It specializes in globe, gate, and check valves.

Rotork, Chennai Tamil Nadu

The extensive,

state-of-the-art Jigani plant, situated in Bangalore, was built in

2010. The Rotork plant provided additional manufacturing

capacity for the burgeoning Indian valve actuation markets, complementing

the existing Rotork factory at Chennai, which also received

substantial investment for expansion.

The Jigani plant is

designed to manufacture product ranges from Rotork Controls, Rotork Fluid

Systems and Rotork Gears, including two assembly lines for the local

manufacture of the IQPro intelligent electric actuator range.

The latest generation of

Rotork Skilmatic SI3 electro-hydraulic actuators have been supplied to one

of India’s leading state-owned oil companies to operate 42" and

48" triple offset butterfly valves on vital safety-related tank farm

duties.

SchuF, Coimbatore. Tamil Nadu

The SchuF Group designs and manufactures

industrial valves that control, isolate, divert, or sample gases, liquids,

slurries or powders. The range of industrial valves are ideal for difficult

or severe service conditions found in the chemical, petrochemical, polymer,

oil, gas, refining and offshore industries.

SchuF has developed five leading valve

designs for coal gasification. From the very earliest coal gasification

plants in South Africa (Sasol) to the latest installations in the USA (GE,

and Valero) to Shell and Siemens in Europe, you will find SchuF valves.

Mission Energy is holding a conference on

coal gasification the 27th and 28th of November in New

Delhi. Valves are crucial components in the many severe service

applications in gasifying coal to make syn gas or liquids. In

light of the fighting and uncertain supply of Middle East LNG, India will

be looking closer at the coal gasification alternative. So, this conference

will be a good one for IVAMA members.

Trillium, Hubli, Karnataka

Trillium Flow Technologies (“Trillium”)

was formerly Weir Flow Control (“WFC”), until earlier this year.

It consists of the same 15 established global pump and valve

brands servicing the power generation, oil and gas, water and wastewater,

mining, and industrial sectors. These include: Sarasin-RSBD™,

Blakeborough®, Atwood & Morrill®, Hopkinsons®,

SEBIM™, BDK™, Batley Valve®, AutoTork™, and Tricentric® for

valves, and Gabbioneta™, WSP™, WEMCO®, Roto-Jet®,

Floway®, and Begemann® for pumps.

Some years ago, Weir purchased BDK. It is based in

the southern state of Karnataka, BDK specializes in valve manufacturing for

energy sectors. At the time the Weir Group already owned two other Indian

facilities in the mining and power station sectors

In 2017 BKK secured a £1.4m contract to supply Indian

EPC contractor M/S Tata Projects Ltd with innovative butterfly valves. The

valves are to be installed in the Sri Damodaram Sanjeevaiah thermal power

station, a coal-based plant with 1600 MW capacity located near Andhra

Pradesh. Weir BDK™ is working closely with M/S Tata

Projects to ensure optimal service-life on their new valves and in turn,

improve efficiencies across their power station.

This order comprises a range of specialized Butterfly

valves with sizes up to 2900mm, featuring hydraulic cylinders, which are

custom designed to deliver resilience in high temperature applications and

dependable service-life.

Velan, Coimbatore, Tamil Nadu

Velan operates a modern 100,000 FT2 valve

manufacturing plant in India. It incorporates the latest

technologies such as robotic fusion welding. There is an

integrated cleanroom where final processing of valves required to be ultra

clean are assembled. Details are explained in a YouTube video. https://www.youtube.com/watch?v=fvyQQee6hKk

Velan Valves are used at Barth 1-3

Supercritical Units of National Thermal Power Corp. Technoprom

Export purchased $20 million worth of valves from Velan

Inc. for the three 660-MW units. The Velan German sales distribution

subsidiary, Velan GmbH, booked the order which included

high-pressure gate, globe, and check valves and steam traps manufactured by

Velan, as well as safety valves with silencers, control valves, butterfly

valves, and actuators manufactured by six other companies in Europe. Here

are other details from the McIlvaine World Power Generation

Projects: Location: India, Bihar’ Startup

Date: 2013,Size: 1980 MW, Primary Fuel: Coal

Coal Gasification Conference Next Month in India

GASIFICATION INDIA 2019 will be held November 28-29 in New Delhi.

http://gasification2019.missionenergy.org/

It is an all-inclusive, proficient platform

that provides an in-detail analysis of extensive drivers, challenges,

restraints, opportunities, present market trends and approach influencing

the global gasification industry together with projections and forecasts.

GASIFICATION INDIA 2019 covers processing technique, investment plan, services

as well as network management. In addition, it discusses gasification

supply chain, financial support, retailers' analysis, and marketing

channels. Moreover, it describes gasification market entry strategies,

opportunities and development challenges predicting the future growth of

the gasification market across the globe by integrating the information

with relevant findings.

In our Alerts in the last

few months we have reported on the Chinese initiative to rely less on LNG

and more on a $30 billion pipeline being built by Sinopec to move gasified coal

to cities around the country as a fuel for turbines and furnaces. With the

uncertain future in the areas of current LNG production this is a prudent

decision. India is in a similar situation with little local

availability of natural gas but abundant coal.

One of the

challenges of successfully operating a gasification plant is to

purchase reliable valves to handle the severe conditions. One of the

gasification India sponsors is a valve manufacturer. Antiwear is a leading

valve manufacturer that can produce ball valve, butterfly valve, double

wedge gate valve, blow back valve, sliding plate valve, check valve,

regulating valve, rotating disc valve and other special functional valves.

Antiwear-supplied valves are widely used in the coal chemical industry. And

Antiwear has been qualified by Shell-SCGP, OMB, Pall and other gasifier process technologies.

Moreover Antiwear has many experiences

supplying valves for GE-Texaco,

Shell-SCGP, E-GAS, U-GAS, HY-GAS, R-GAS, HT-L, Trigger, Siemens

GSP, CHOREN and

other gasifier technologies. Antiwear is appreciated by more and more

clients due to perfect performance of the valves including lock hopper unit

valve, oxygen service valve, BBV, metal and soft-seated ball valve,

triple-offset valve and other functional valve.

After more than a year of operation, Shenhua Ningxia coal converts

more than 4 million tons of coal-to-liquid products by indirect

liquefaction. Antiwear provided over 300 sets of valves including ball and

other types. The double disk valve has performed without jamming,

leaking or deterioration.

The project successfully broke the foreign

monopoly on the coal chemical industry core technology due to performance

of the valves compared to those from international companies.

Click here to un-subscribe from this

mailing list

|