|

WELCOME

Weekly selected highlights in flow

control, treatment and combustion from the many McIlvaine publications.

·

India APC Opportunity

· Effect of Interference on the

Combust, Flow, and Treat Markets

· Sucking CO2 Out of the Air Means

There is No Tipping Point

· Biomass Ready Coal Fired Plants and

Massive Tree Planting will be the Compromise Climate Change Solution

· Utility Tracking System has Details

on All Coal Fired Operators Around the World

·

The Future of

Biopharmaceuticals will Depend on Perceived Value vs Cost

India APC

Opportunity

The next FGD

newsletter will include the analysis of participant companies in

SOx-NOx India. It is partially

displayed below. Also displayed are

the headlines to the September FGD newsletter. This news letter is part of 44I

Coal Fired Power Plant Decisions.

This service

also includes the Fabric Filter

Newsletter, Electrostatic Precipitator Newsletter, and IIoT and Remote

O&M newsletter.

It includes an intelligence system with

webinars, case histories and papers. There is no cost to this service

for power plant owners. The cost for others is $1600/yr for one

subscriber and $120/yr for additional subscribers from the same company.

We are in

discussions with Mission Energy relative to future webinars and will be

focused on ways to assist India in making its air. water and solid waste decisions.

FGD and

DeNOx

NEWSLETTER

September

2019

No.

497

TECHNOLOGY

- Wet Lime Systems Have a

Number of Benefits Compared to Limestone Systems

- India Needs Additional

High-Quality Hydrated Lime Production

- Circulating Fluid Bed

Scrubber Could Be the Best Choice for Many Indian Power Plants

- Enhanced Hydrated Lime

(EHLS) Has a Number of Advantages

- Improving the FGD Absorber

and ESP Performance at Iskenderun Power Plant

- Valves for Spray Tower Type

FGD System

- High Priority on Valve

Specifications for Indian Limestone FGD Systems

- The Shower Versus the

Bubble Bath Principle for FGD

- Indian Power Lobby Presses

for Further Delay in Pollution Standards

- Determining True Cost for

Dry Scrubbing through Coal Fired Power Plant Decisions

- Upgrading Limestone

Scrubber System

- Summary of Air Emissions

from the First Year Operation of Jea’s Northside Generating Station

- Upgrade FGD Systems with An

Absorber Tray Says B&W

COMMERCIAL

- Carmeuse Exporting Lime to

India from Oman

- Chiyoda and Larsen &

Toubro are Offering the Chiyoda FGD Systems to Indian Power Plants

- Thermax and MET Pursuing

South Asian Market with Wet and Dry FGD Technology

- TSGenco Moving Forward with

Air Pollution Control Upgrades at Four Units Totaling 1800 MW

- Yokogawa Process

Optimization Reduces Yearly Costs in Limestone FGD System in Japanese

Power Plant

- Analysis of Indian FGD

Suppliers

- Doosan Is Active in India

and Around the World in the Full Range of APC Equipment

·

Indure

Is A Large Indian EPC Company with APC Licenses

- BHEL Is the Leading

Supplier of Power Plants and FGD Systems in India

- ISGEC Has Licenses from

Multiple International APC Suppliers

- GE Is the Second Largest

FGD Supplier in India

- Hamon Indian Subsidiary

Selling Cooling Towers, Chimneys and Air Pollution Control Equipment

in India

- Rieco Offers A Limestone

FGD System with A Venturi Scrubber for Particulate removal

- Andritz Offers Wet and Dry

FGD Systems in India

- Larsen and Toubro Designs

Plants, Air Pollution Control Systems and manufactures Components Such

as Valves

- Circulating Fluid Bed

Scrubber Could Be the Best Choice for Many Indian Power Plants

- Adage Automation Supplies

127 CEMS For Reliance Industries

- Bids Close for DSI for 4 x

210 MW of DSI Systems at Punjab State Power Roopnagar In September

2019

- Tata Power March 2019 Bid

Request For 1x67.5-MW DSI FGD System

- Valmet Uses the Condensing

Scrubber Technology to Recover Heat

- JGC Supplying Dry Scrubbers

and NOx Control

- Mississippi Lime Completes

Acquisition of Southern Lime

- Fortum Has Combustion

Modification Order from Hindalco

- BHEL Has 13 Orders for

Selective Catalytic Reduction (SCR) System to Reduce NOx

- BHEL Has Order for FGD

Systems at the 4x250-MW Nabinagar Project of BRBCL

- ECOMAK Supplies

Precipitator Upgrades and the Venturi Option Could Be Combined With

FGD

- United Conveyor Has Dadri

Order For DSI

- Envea Pursuing FGD CEMS

Market in India

- Johnsen Chemicals Has A

Combustion Catalyst That Lowers Pollutants

- EPP

Provides FRP Scrubber Vessels

- Uniphos

Provides Particulate and Gas CEMS

- LeBracs

Supplies Rubber Lining for Vessels and Ducts

- Carmeuse

Exporting Lime to India from Oman

- Sorbacal® SPS

Used in CDS and DSI Systems

- Lhoist

Announced Possible Price Increases of 11 percent Last December

- Lhoist

Market Share in Asia

CONFERENCES

- Leveraging

DSUA Expertise to Assist Indian Utilities Participating in SOx-NOx

Conference

Analysis of

SOx-NOx India Participating Companies

We have been

reporting on SOx-NOx India in the months leading up to the event last

month. This included a webinar with S. Dalvi of Mission Energy as a

featured speaker. The conference was quite successful in providing insights

needed for the very ambitious air pollution control program which is being

undertaken.

We reported

earlier on the speakers and exhibitors. Now we are reporting on the

attendees. There were one or more

attendees from each of the companies described below. They include end

users, suppliers, governmental agencies, and consultants. The combined

knowledge is invaluable. It will be

12 months before the next conference, but the information exchange can be

expanded into an ongoing program to serve as bridge.

We are working

with Mission Energy to schedule regular webinars. We are also offering 44I Coal Fired Power Plant Decisions free of charge to Indian utilities and

industrial power generators. The papers from the previous conferences plus

the Decisions service will provide the basis for high level webinars.

The decisions

on wet limestone FGD have already been made by many plants. But there still

are component decisions such as controls, oxidation blowers for the sulfite

recycle system, belts for the gravity filter systems, and certain critical

valves and pumps. It has been found that even coupling decisions can be

important.

For 80,000 MW

of projects for which designs have not been finalized there are many

important issues to resolve. These

include:

· Consideration

of natural oxidation lime systems with chemical fixing of sludge for use in

landfills. The capital cost is only 60% of the limestone forced oxidation

gypsum system. This may make sense

for older plants.

· Determining

whether wet systems, dry sorbent injection, spray dryer absorber,

circulating fluid bed absorbers or even a salable product such as ammonium

sulfate or sulfuric acid is the best choice.

· Determining

how much particulate will be removed in the scrubber. The use of a rod deck

as the first stage in the absorption tower can reduce particulate emissions

by 50%. Consideration of the compromise climate change solution Sucking

CO2 Out of the Air Means There is No Tipping Point, Biomass

Ready Coal Fired Plants and Massive Tree Planting will be the Compromise

Climate Change Solution. A number of small older coal-fired plants are operated

by attendees such as the cement and textile companies described below. The

long-term program would be to plant lots of trees to suck out CO2

and when they reach end of life, use them for fuel. One of the attendees, Valmet is helping

companies convert from 100% coal to combination fuels. So, there are lots of

options to explore in webinars.

ADAGE AUTOMATION - we covered their stand display of

automaton and CEMs previously.

ASHLAND is an international supplier of

resins for FGD and covered in 66

articles in the Alert and many more in the FGD newsletter.

BHARAT LIME ASSOCIATION was formed

solely…To promote,

particularly in India, the advancement of the knowledge of limestone,

dolomite stone, lime and calcined dolomite-related products among its

existing and prospective members and also bring into contact those engaged

in these pursuits, with a view to developing a synergy among them

particularly the industry, the professionals, the academia and R & D

Institutions.

To receive,

edit, publish and distribute papers, periodicals or journals, books and

hold Conferences, Meetings, Symposia, Colloquia, Workshops on relevant

themes and subjects and to set up Libraries as and where convenient and

also to exchange journal and other publications with similar materials

published elsewhere and to establish interrelationship in mutual interest

with similar bodies in different parts of the world. The association is

linked to the National Lime

Association in the U.S. and to the international and British

associations as well.

BHARATI CEMENT is a division of Vicat in India. It

functions in 3 verticals - Cement, Aggregates and Polymers with a

team of over 850 professionals and operations spread across 7 states in

India

BOKARO POWER SUPPLY COMPANY PVT. LTD. (BPSCL) established in 2001 is

a Joint Venture Company of Steel

Authority of India Ltd. (SAIL) and Damodar Valley Corporation (DVC) and is

engaged in power and steam generation and supplies power and steam (at

various pressures) to SAIL’s Bokaro Steel Plant (BSL) located at

Bokaro for meeting the process requirement of BSL.

The BPSCL

Power Plant is located on the premises of the Bokaro Steel

Plant (BSL) and has an aggregate installed capacity to generate

302 MW of power besides 660 Ton per Hour (TPH) of steam.

The Plant has

9 boilers (5 boilers each of 220 TPH, 3 boilers each of 260 TPH capacity

and 1 boiler of 300 TPH) and 7 turbine generators (one 12 MW back Pressure

Turbine Generator (TG), 2 TGs each of 55 MW capacity, 3 TGs each of 60 MW

capacity and one 36 MW back Pressure Turbine Generator).

CARMEUSE lime and limestone activities have

been covered in many of the 2000 previous Utility E-Alert issues. Also, their activities as Dravo Lime,

including natural oxidation and chemical fixing using high magnesium lime,

have been reported.

CHEMICAL

PROCESS EQUIPMENT supplies FRP

tanks, piping and other FRP products used in power and FGD

CHEMTRON PROCESS EQUIPMENTS provides wastewater and water

treatment systems.

CHEMTRON

SCIENCE LABORATORIES supplies

calibration gases.

CHATTISGARTH

STATE POWER is a major

operator of coal-fired power plants. There are 133 articles about them in

previous Utility E-Alerts, including an order placed with BHEL for an FGD system

appearing in the September 13, 2019 Alert.

CHRISTIAN

PFEIFFER makes FGD ball mills. They gave a

presentation at 2018 SOx-NOx http://soxnox2018.missionenergy.org/presentations/Christian%20Pfeiffer.pdf

COAL PREPARATION SOCIETY OF INDIA’s main objective is to promote washing of domestic coal

with high ash content to improve its heat value, improve its combustion

with reduced emissions and make it environmentally acceptable and

sustainable fuel for economic development and long-term energy security.

COUNCIL ON ENERGY, ENVIRONMENT, AND WATER is an India-based but globally engaged

research think-tank, which analyses and advises on critical questions

concerning energy, environment and water. It publishes analyses such as https://www.ceew.in/publications/clean-energy-investment-trends-2019

CPCB has its head office in New Delhi, with seven

zonal offices and five laboratories. The board conducts environmental

assessments and research. It is responsible for maintaining national

standards under a variety of environmental laws, It has responsibilities to

conduct monitoring of water and air quality and maintains monitoring data.

The agency also works with industries and all levels of government in a

wide variety of voluntary pollution prevention programs and energy

conservation efforts. It advises the central government to prevent and

control water and air pollution.

DESEIN INDURE with its headquarters in New Delhi, India, is

a leading engineering consultancy organization with over 38,000 MW of

experience in setting up coal/lignite-fired power plants as well as gas

based simple and combined cycle power plants with unit sizes ranging up to

800 MW, which is the largest size single unit of supercritical technology

currently under implementation in India. In 1987, DESEIN set up a

separate division to provide environmental engineering solutions to

mitigate pollution arising out of new projects. Since then, a group of

specialists in this field has undertaken field studies to determine the

impact and suggest remedial measures for setting up of more than 80 large

power projects with a cumulative capacity of around 62,000 MW of power in

India.

ECOMAK provides dry and semi dry FGD systems plus venturi

scrubbers and fabric filters.

ENGINEERS INDIA LIMITED (EIL) is an engineering consultancy, and engineering, procurement

and construction (EPC) company in the power, hydrocarbons and

petrochemicals industry. The company's segments are Consultancy &

Engineering Projects, and Turnkey Projects. Its services include technologies,

pre-Front End Engineering Design (FEED) and FEED, project management,

procurement services, construction services and specialized services.

ENVIRONNEMENT supplies CEMS and instrumentation with many articles about

them in the Alert and Monitoring newsletter (now IIoT and Remote O&M).

EPP COMPOSITES supplies FRP

vessels and piping and has a new partnership with Plasticon.

GE-BH supplies valves for coal-fired power

plants.

HINDALCO is the world's largest aluminum rolling company and is

also a leading producer of copper. Along with its global subsidiary Novelis Inc., Hindalco has a

presence in 12 countries. The company operates across the value chain from

bauxite mining to alumina refining, aluminum smelting and rolling and

extrusions. It operates coal-fired power plants including 6 x 150 MW at one

location. from

bauxite mining to alumina refining, aluminum smelting and rolling and

extrusions. It operates coal-fired power plants including 6 x 150 MW at one

location.

HINDUSTAN ZINC has 474 MW of coal-fired boiler capacity.

HITACHI ZOSEN supplies air pollution control equipment,

including dry scrubbers and NOx control.

HORIBA is an international supplier of CEMs and air and water

instrumentation. There are a number of articles about this company in the

Alert and Monitoring newsletters.

IMAGICO is a

Mumbai-based company that manufactures high quality colorants and pigment

dispersions for paints, printing inks, paper, textiles and various other

products.

INDIAN FARMERS FERTILIZERS - Indian Farmers Fertilizer Cooperative Limited (IFFCO) is

one of India's biggest cooperative societies which is wholly-owned by Indian Cooperatives. It

operates coal-fired boilers.

INDUS ENERGY CONSULTANTS was incorporated in December 2017, by a team from

the power and steel industry

with over 20+ years of individual experience. It operates in the field of

Electrical Transmission & Distribution, Power Generation and Structural

Steel Fabrication.

INEOS has just acquired Ashland

Composites. It is one of the

world’s largest chemical companies and the 50th largest

business in the world, employing around 20,000 people across 171 sites in

24 countries. It is a privately-owned company with sales in 2018 of $60

billion and EBITDA of $7 billion.

ISGEC is a multi-product, multi-location

public company, which has been providing engineering solutions

to customers across 91 countries for the past 85 years. There are multiple

partners for air pollution control equipment.

ENVIROTHERM GMBH, GERMANY for Electrostatic Precipitators (ESP) up to 1000 MWe

(Tumbling Hammer Design) Indigenous Top Rapped Compact Design for Industrial Range

Boilers/ Other Applications Experience: More than 150+ ESP Installations, with biggest

unit of 180 MW.

FUEL TECH INC., USA - For reduction of Particulate Matter emissions by use of

Electrostatic Precipitators performance improvement technologies

(especially Flue Gas Conditioning). For NOx reduction

processes by use of urea or ammonia (SCR and SNCR).

BABCOCK POWER ENVIRONMENTAL INC., USA - For Wet Limestone-based Flue Gas Desulfurization Systems of

more than 100 MWe Unit Size.

ISGEC REDECAM ENVIRO SOLUTIONS PVT. LTD. - For Bag Filters

and Hybrid Filters for all industrial applications; for ESP's for Ferrous,

Non-ferrous and Cement Industry for Dry DeSOx solutions (Dry Sorbent

Injection & Circulating Dry Scrubber) for Industrial Applications.

SUMITOMO SHI FW - ISGEC is the partner for CFB

boilers and CFB dry scrubbers. A

joint ISGEC/ SHI FW webinar was held in India in June. Presenters

were Robert Giglio | Senior Vice President of Strategic Planning

and Business Development | Sumitomo SHI FW,

Asif Hussain | Senior

VP of Strategic Business Development | Sumitomo SHI FW, Greg Szulc |

Commercial Manager | Sumitomo SHI FW and Niranjan Shastry | Senior Vice

President | ISGEC Heavy Engineering Limited.

JK

CEMENT is the second largest manufacturer of white cement

in India, with an annual capacity of 600,000 tons. It is also the second

largest producer of wall putty in the country with an annual installed

capacity of 700,000 tons. JK Cement was the first company to install a

captive power plant in the year 1987 at Bamania, Rajasthan. J.K Cement is

also the first cement company to install a waste heat recovery power plant

to take care of the need of green power. Today at its different locations,

the company has captive power generation capacity of over 140.7 MWs which

include 23.2 MW of waste heat recovery power plants.

JGC is a designer of power plant systems with a

recent order in the Philippines. It also offers a dry scrubber system which

has been successfully employed in Japan.

JIANGAN ENVIRONMENTAL supplies SO2

scrubber systems using ammonia to produce ammonium sulfate. It has many

installations in China

JOHNSEN CHEMICALS was established in 2008 and has since

been working on the development of a catalyst for solid fuel. The product

has been tested on several markets with good results. The results show that

the catalyst contributes to a reduction of harmful emissions while also

making the combustion process more effective with a lower consumption of

fuel. Sootaway is a combustion catalyst

for solid fuel. The active ingredient is a manganese complex. The catalyst

works on all types of solid fuels.

KOCH-GLITCH provides mist eliminators for FGD systems.

There are many articles about their experiences in the Utility E-Alert and

discussions of their separation ability vs. particle size in the FGD &

DeNOx newsletter.

LEBRACS RUBBER LININGS is a rubber lining manufacturer supply tank

linings.

LOGIC LADDER provides

energy and environment intelligence technology including CEMS software that

makes data simple to acquire, understand and act upon.

LUEHR

FILTER is teamed with Ecomak

supplying APC equipment and is widely

covered in the Fabric Filter newsletter.

MAGO

THERMAL provides biomass capable boilers, venturi scrubbers,

sieve trays, dry scrubbers, and double alkali systems.

MAHARASHTRA STATE POWER GENERATION (Mahagenco) has the highest overall generation

capacity and the highest thermal installed capacity among all the state

power generation utilities in India. In terms of installed capacity, it is

the second highest generation company after NTPC. having generation capacity of 13,602 MW comprising

10,170 MW thermal, 2,580 MW hydel, 672 MW gas turbine and 180 MWp solar. It

was established by the government of Maharashtra under the central

electricity act-2003 with the principal objective of engaging in the

business of generation of electricity,

MAXIMA FRP PRODUCT supplies FRP for scrubbers, blowers,

tanks and chimneys.

MECS

INDIA is part of Dupont

Clean Technologies, which furnishes Dynawave scrubbers and also

complete systems to make sulfuric acid from SO2. It also supplies ozone generation systems

in combination with the Dynawave to absorb NO2 resulting from

the reaction of NOx and ozone.

McIlvaine recently analyzed this potential for one power plant,

which only needed modest NOx removal and found that this was

much more economical than adding SCR.

MELCO INDIA supplies

bottom ash and flyash transportation systems as well as slurry pump repair

parts.

THE MINISTRY OF ENVIRONMENT, FOREST

AND CLIMATE CHANGE (MoEF&CC) is the nodal agency in the

administrative structure of the Central Government for the

planning, promotion, co-ordination and overseeing the

implementation of India's environmental and forestry policies and

programs. The climate change program McIlvaine outlined to make future

coal plants biomass capable and to plant millions of trees, is a

combination which this agency already has within its scope

NTPC is the largest power generator in India

and one of the largest in the world. There are hundreds of articles about

its activities in the Alert and various McIlvaine newsletters. There is

detailed reporting of each proposed FGD project and the status of those

underway.

OPG

POWER GENERATION is a developer and operator of power

plants in India with 414 MW of thermal capacity.

ORIENT

CEMENT began cement production in the year

1982 at Devapur in Adilabad District, Telangana. In 1997, a split-grinding

unit was added at Nashirabad in Jalgaon, Maharashtra. In 2015, Orient

Cement started commercial production at its integrated cement plant located

at Chittapur, Gulbarga, Karnataka. With a total capacity of 8 MTPA, they serve

Maharashtra, Telangana, Andhra Pradesh, Karnataka and parts of Madhya

Pradesh, Tamil Nadu, Kerala, Gujarat and Chhattisgarh. It has a 50 MW

coal-fired power plant with ESPs.

PLASTICON is a major supplier of FRP tanks,

lining, etc. and has a joint venture with EPP in India. There are many articles on Plasticon in

the FGD & DeNOx newsletter.

RELIANCE

INDUSTRIES - The company is the sole distributor

of electricity to consumers in the suburbs of Mumbai. But in 2017 they

sold the Mumbai operation to Adani

Power. It also runs power generation, transmission and distribution

businesses in other parts of Maharashtra, Goa and Andhra Pradesh.

With its subsidiaries, it is developing 13 medium and large-sized power

projects with a combined planned installed capacity of 33,480 MW.

RIECO INDUSTRIES

supplies wet FGD systems, fabric filters and other APC equipment.

RSWM is a large textile manufacturer with coal-fired power

generation.

SMARTLUTH provides power plant management software.

STEAM EQUIPMENTS

provides air and water analysis systems.

SWAN ENVIRONMENTAL

is a major international supplier of air and water instruments. There are many articles on their power

plant activities in Monitoring (now IIoT newsletter).

TALEC ENGINEERING solves

APC problems. NTPC Ltd. was experiencing flow issues on the

Selective Catalytic Reduction (SCR) reactor due to ash buildup. In a pilot

project overseen by YARA

Environmental Technologies, the SCR was installed on a trial basis

with the intent to reduce NOx (nitrogen oxide) emissions. Talec

Engineering Pvt. Ltd. was brought in to consult and install equipment which

included a Martin air cannon.

https://static.martineng.com/www.martineng.in/Talec%20NTPC_PSP%20.01D%20(1)%20(1)%20(1).pdf

TELANGA STATE POWER GENERATION has

increased its installed power generation capacity to 16,506 MW from 7,778

MW in 2014 when the State was formed making it into one of the fastest

growing sectors in the country. The Telangana government is now gearing up

to increase the total capacity to 28,400 MW over the next 4-5 years.

TETHYS INSTRUMENTS is a manufacturer of gas and

water on-line analyzers for environmental and process applications.

THE RAMCO CEMENTS

LTD, manufactures Portland Cement

in eight state-of-the art production facilities that includes

Integrated Cement plants and Grinding units with a current total production

capacity of 16.45 MTPA (out of

which Satellite Grinding units capacity alone is 4 MTPA). The

company is the fifth largest cement producer in the country. Coal-fired

generators have been supplied by Thermax. https://www.thermaxglobal.com/thermax-power-generation-solution/thermax-power-plants/power-plant-projects-and-solutions/

SINGARENI COLLIERIES COMPANY

LIMITED (SCCL) is

a government coal mining company jointly owned by the Government of

Telangana and the Government of India on a 51:49 equity basis. The

Singareni coal reserves stretch across 350 km of the Pranahita – Godavari

Valley of Telangana with proven geological reserves aggregating to whopping

8,791 million tons. SCCL is currently operating 18 opencast and 30

underground mines in 4 districts of Telangana with a manpower around

48,942.

TATA POWER

Presently, thermal power accounts for

around 70 percent of Tata

Power’s portfolio. But the current energy mix is part of the

company’s long-term legacy before 2013 when renewable energy was pricier

compared with competitive coal-fired power.

“The company’s plan, ‘Strategic Intent 2025’ calls for up to 70

percent of new capacity additions to come from solar, wind and hydro

through to 2025. This represents a significant departure from the accepted

wisdom of just a few years ago that a major expansion of coal-fired power

would be required to serve India’s growing electricity demand”, said Simon

Nicholas, energy finance analyst at IEEFA.

The majority of Tata Power’s thermal capacity is

now centered on its 4,150 MW Mundra coal-fired power plant - one of the

biggest power plants in India - which experienced losses reaching $191

million for the first three-quarters of FY 2019. See detailed analysis in

the July 19 Utility E Alert

Thermax

Limited has concluded an

order of INR 471 crore from an Indian government power company to set up

two flue gas desulfurization (FGD) systems at their thermal power plant in

the state of Jharkhand.

As a part of

the customer’s drive to meet the mandates for regulating SOx emissions from

coal fired power plants, they plan to install two units of FGD systems of

500 MW capacity each at their plant.

“Since its

inception, Thermax has been one of the key contributors to the nation’s

pollution abatement journey by providing sustainable solutions. This

prestigious order reinforces our capabilities in supporting power plants to

meet the stringent emission laws laid by the government in line with its

commitment to the environment,” says M.S. Unnikrishnan, MD & CEO,

Thermax Limited. See details in

July 19 Alert.

TORRENT POWER - Torrent has thermal power generation capacity of

3,092 MW with a unique mix of coal and gas-based power plants that use the

latest power generation technologies to ensure high thermal efficiency. It

also operates in the renewable energy segment with 610.5 MW operational

plants and 851.3 MW plants under-construction, taking the total renewable

generation capacity to 1461.8 MW.

ULTRATECH CEMENT LTD. is the largest manufacturer of

grey cement, Ready Mix Concrete (RMC) and white cement in India. It is also

one of the leading cement producers globally. The company has a

consolidated capacity* of 102.75 Million Tonnes Per Annum (MTPA) of grey

cement. UltraTech Cement has 20 integrated plants, 1 clinkerization plant,

26 grinding units and 7 bulk terminals. Its operations span across India,

UAE, Bahrain, Bangladesh and Sri Lanka. UltraTech Cement is also India's

largest exporter of cement reaching out to meet the demand in countries

around the Indian Ocean and the Middle East. 4 x 25 MW coal-fired plants are described

at http://www.holtecnet.com/holtecdocs/Brochures/cpp-whr-list.pdf

UNIPHOS ENVIROTRONIC PVT. LTD is the only Indian manufacturer of chemical detector

tubes, electrochemical gas sensors and pellistors for combustible gases.

The company also supplies Continuous Emission Monitoring System (CEMS),

Ambient Air Quality Monitoring System (AAQMS), Water Quality

Analyzers, and Oil Quality

Analyzers.

UNITED CONVEYOR makes flyash handling

equipment and also direct sorbent

injection systems which are being supplied to the Dadri power plant and

will be the first large scale power plant application of DSI in India. Hundreds of articles on United

Conveyor appear in the Alert, FGD & DeNOx, Precipitator, Fabric Filter

and other McIlvaine newsletters.

VALMET can help convert older Indian coal-fired

boilers to a combination of biomass and coal. (see introduction) In

Finland, Valmet

delivered a CFB boiler with 100-percent coal-firing capacity and a design

fuel mixture that also includes wood-based biomass (0–75 percent),

agro-based biomass (0–15 percent), peat (0–95 percent) and solid recycled

fuel (0–5 percent).

The target is to run the plant 70 percent on biomass. In order to

run purely on biomass, the plant would have to make an additional

investment. Valmet’s delivery also included flue gas cleaning systems and a

wide range automation solutions, for example, for monitoring emissions and

managing energy consumption.

VASTHI INSTRUMENTS manufactures the following instruments: Gas Analyzer, Gas Detectors, Dew Point

Meter, Dew Point Analyzer, Online Dew Point Meter, Portable Dew Point

Meter, Particulate Monitors, Stack Gas Analyzers, and have been supplying

instruments to customers worldwide.

VIRGINIA

MINING RESOURCES (VMR) is incorporated in the United States.

It provides mining services and

expertise in coal mining in the U.S. The company is currently actively

pursuing expansion of its mining footprint internationally with focus in

India. VMR’s India operations are initially concentrating on coal and

iron ore mining. This includes management of mine operations through

planning, design and development in long-term contractual basis

through the Mine Development Operation (MDO) and Public Private Partnership

(PPP) concepts in the public and private sector.

W.L GORE supplies mercury and SO2 capture

polymeric absorbers. It also

supplies Gore-Tex media and bags for particulate capture. There are hundreds of articles and

recorded webinars in the McIlvaine publications on Gore technology. Mark

DeGarboewski was a speaker at SOx-NOx and Jeff Kolde was an attendee.

We will be

working with Mission Energy, the attendees and suppliers to move forward

with a program to maintain the momentum achieved at the conference. More

information on the decisions service with the 4 newsletters, intelligence

system and webinars is available at 44I

Coal Fired Power Plant Decisions.

If you have

suggestions relative to webinars for

India you can contact Bob McIlvaine at rmcilvaine@mcilvainecompany.com, Direct 847 784 0013 and cell 847 226

239l

Effect of Interference on the Combust,

Flow, and Treat Markets

The combust,

flow, and treat (CFT) products and services markets will exceed $400

billion next year. The market has typically been segmented by McIlvaine on

geographical end use. However, this analysis is based on where the profits

are generated. India and Italy are major exporters of valves. Africa will

enjoy a rapidly increasing market but China will be one of the main

beneficiaries in terms of CFT products and services. It is building complete

power plants and mines and, in many cases, taking part ownership of them.

The market in

2030 is likely to rise to just under $600 billion if there is a lack of

government interference. However if

there is interference in the markets the revenues could only rise to $535

billion.

Interference

is a label which applies to tariffs, military destruction of refineries and

greenhouse gas legislation as well as similar factors not experienced

previously. The world has enjoyed a policy based on the principle that a

rising tide floats all ships. Even though the U.S. and Europe are

experiencing shrinkage in terms of percentage of world consumption within

their borders they have managed to export or produce goods in Asian

countries and take advantage of the growing prosperity in that region.

|

Region

|

2020

|

2025

|

2030

|

|

|

Free

$ mil

|

%

|

Inter-

ference

$ mil

|

%

|

Free

$ mil

|

%

|

Inter-ference

$ mil

|

%

|

Free

$ mil

|

%

|

Inter-ference

$ mil

|

%

|

|

Asia

|

176

|

43

|

174

|

43

|

234

|

48

|

232

|

50

|

303

|

51

|

305

|

57

|

|

EMEA

|

100

|

24

|

100

|

24

|

117

|

24

|

107

|

23

|

119

|

20

|

102

|

19

|

|

Americas

|

134

|

33

|

136

|

33

|

137

|

28

|

126

|

27

|

173

|

29

|

128

|

24

|

|

Total

|

410

|

|

410

|

|

488

|

|

465

|

|

595

|

|

535

|

|

The U.S. and

the U.K are embarked on policies which will reduce the total market and

ultimately decrease their percentage share of a smaller pie. If the U.S. continues aggressive tariff

implementation it might see a slight increase in CFT revenues next year but

by 2030 it will encounter a smaller market and a smaller market share for

its CFT companies.

The U.S. is in

an enviable position due to hydraulic fracturing and its leading position

as an oil and gas producer. However,

China is aggressively pursuing fracturing and coal to syngas and liquids.

It is also pursuing fracturing in the Middle East and Argentina. Sinopec is already the world’s largest

CFT product consumer and a major supplier as well. By 2030 it is likely

that low cost oil and gas will be produced by fracturing in several

countries.

In a free

environment the role of governments and even geography become secondary

whereas the role of multinational corporations becomes paramount. This includes CFT purchasers such as Shell, BASF, Pfizer, and Arcelor

Mittal. It includes suppliers such

as GEA, GE, Xylem, Doosan, Shenhua Guodian and MHPS. The international suppliers can deal with

the international purchasers. Since

many international suppliers are in Europe and the U.S. these locations

benefit from the free environment. Government imposed restrictions will

reduce the market and role of these major companies and decrease the

prosperity of the countries in which they are home based.

The actions to

fight climate change are another variable.

Under an extreme scenario CO2 reduction could be prioritized

regardless of consequences. In a compromise plan such as proposed by

McIlvaine there would not be a negative impact on the economy and the CFT

market.

The

interference variables need to be considered in all the CFT market

forecasting. All the long range forecasts appearing in the specific McIlvaine

market reports are updated continually to reflect these variables. http://home.mcilvainecompany.com/index.php/markets

Bob McIlvaine

can answer your questions at rmcilvaine@mcilvainecompany.com

direct 847 784 0013 cell 847 226 2391

Sucking CO2

Out of the Air Means There is No Tipping Point

There is the

widely held belief that we could reach some tipping point after which we

are helpless to combat the greenhouse gas problem. However, as reported by McIlvaine last

week, there is a way to suck the CO2 out

of the air. So this does not make us helpless. There is a cost

associated with the removal effort but it will be far less than drastic

preventive measures such as eliminating all fossil fuels.

The UK is

leading the way with a program to burn biomass in its largest coal fired

boiler. If the resultant CO2 is sequestered, the net effect would be to

achieve two thirds of the entire CO2 reduction goals for the nation.

The analysis

last week shows the conclusion of researchers that tree planting would be a

cost effective way to capture most of the excess CO2 generated in the past

200 years. However, the problem is that in 2050 many of the trees will

start dying and we will reach an equilibrium. The CO2 capture from newly

planted trees will equal the amount emitted by decomposing trees. However if all the coal fired boilers

built in the future are biomass capable and can sequester their CO2 then

the tree planting program remains effective.

The present

CO2 level is 410 ppm. In the next 30

years new coal plants in India and other initiatives are likely to have the

impact of increasing CO2 by 1 ppm per year.

But a massive tree planting program could have the effect of

reducing CO2 by more than 1 ppm per year. The net effect would be a 390 ppm

CO2 level in 2050.

|

Initiative

|

2020-2050

ppm CO2

|

2050-2080

ppm CO2

|

|

Existing

|

410

|

390

|

|

New Coal and

Other

|

30

|

20

|

|

Tree

Planting

|

-50

|

0

|

|

Biomass

Combustion and Sequestration

|

0

|

-30

|

|

CO2 level in

the atmosphere at end of period

|

390

|

380

|

After 2050

solar and wind will be more cost effective particularly if energy storage

methods advance. The need for new coal fired plants will cease but there

will be other sources with the potential to add 20 ppm to the atmosphere in

the 2050-2080 time frame.

In 2050 there

will be a very large quantity of fuel contained in elderly trees. They can

be harvested and burned as fuel. They do not emit CO2 to the atmosphere due

to sequestration. New trees which replace the old trees will continue to

remove CO2. So this initiative would

more than offset man made sources and the CO2 level could drop to 380 ppm

in 2080.

CO2

sequestration has been commercially practiced for decades. One use has been

enhanced oil recovery. CO2 is being

piped long distances in many areas. Presently it is economic only if it has

a use such as recovering oil. The UK believes that new carbon capture

technologies will drive down the cost over the coming years. But whether it

is inexpensive or expensive the situation is manageable in 2050 due to the

ability to suck out the CO2. This control provides flexibility. McIlvaine

Company knows that predictions regarding environmental impacts are seldom

precisely accurate. So flexibility is very important.

Robert

McIlvaine has been involved in air pollution control since the original

Clean Air Act. He testified before senate sub committees relative to the

mitigation of acid rain through installing scrubbers at power plants. The

big concern was destruction of forests and buildings. Little was understood

about the potential for SO2 to react with basic chemicals in the atmosphere

and create fine particles which damage the lungs. It was later found that

sulfur has a positive effect on the soil and that some of the isolated

areas of tree destruction were not likely to be duplicated with increased

SO2. However, it is now clear that the sulfate aerosols were a major

problem and more than justified the SO2 reduction.

Dioxin

emissions from waste incinerators are another example of incomplete

knowledge. This concern caused the U.S. to discourage waste to energy

plants in the 1970s and 1980s. The rest of the world discovered that waste

to energy rather than landfilling was much better for the environment. So in most areas of the world you have to

combust rather than landfill waste but do so with removal of the air

pollutants.

The greenhouse

gas effect may be worse or better than the average scientist now believes.

But it is nearly assured that the impact will be different than

anticipated. This is why a flexible policy is so desirable.

Biomass Ready Coal Fired Plants and Massive Tree Planting will be the

Compromise Climate Change Solution

Coal provided

26 percent of the additional power generation last year and 38 percent of

all generation. There are 500,000 MW of new coal fired generation in the

planning stage. This is more than was ever installed in the Americas and

Europe. So any programs to reduce coal fired generation on these two

continents to zero would eliminate less than is being added elsewhere in the

world.

The

intergovernmental panel on climate change has a solution. One trillion

trees can be planted. They will store an

estimated 205 gigatons of carbon, or about two-thirds of the carbon that

humans have added to the atmosphere since the 1800s.

The

problem with this approach is that 30 years from now in 2050 there will be

lots of trees dying and emitting CO2. However at that time the biomass can

be harvested and burned in power generators. If the 500,000 MW of new coal

fired capacity which is built is designed to be biomass ready it can be

converted making each of the generators carbon neutral. If this CO2 is then

sequestered these generators would be as the UK describes it “sucking the

CO2 out of the air. They would be the only generator type which actually

reduces CO2.

What are the costs? The continuation of the coal fired power

program would net a savings of $7.2 trillion over 30 years. The tree planting program would cost $700 billion resulting in a $6.5

trillion saving over the 30 years. For the period 2050-2080 the coal plants

would be converted to burn biomass and sequester CO2. This would raise costs of electricity

generation and make this approach relatively costly.

|

Activity

|

2020-2050

|

2050-80

|

|

Tree Planting

|

-$700

billion

|

-$700

billion

|

|

Saving with coal vs more expensive

generation options

|

$7.2

trillion

|

|

|

Net savings

|

$6.5

trillion

|

|

|

Biomass combustion and

sequestration

|

|

0

|

|

Net cost differential

|

$6.5

trillion

|

-$700

billion

|

In 2050 these

biomass ready coal plants would have already served their purpose as coal

generators. Their conversion to biomass would insure that the forestation

approach is sustaining in terms of CO2 minimization. However if there are

major improvements in the cost of

wind and solar, the plants could be retired.

Another option

is to convert these plants to biomass combustion at an earlier date. There

is optimism that the cost of sequestration can be greatly reduced through programs underway

at Drax and other locations. If some

of the most pessimistic forecasters are right and climate change becomes a

crisis then the biomass generation and sequestration becomes the only route

to solve the problem since it reduces

CO2.

The details on

this approach are continually evaluated in the 42EI

Utility Tracking System.

Bob McIlvaine can answer your questions at

rmcilvaine@mcilvainecompany.com

cell 847 226 2391

Utility Tracking System has Details on

All Coal Fired Operators Around the World

Less than 1000

industrial and utility power companies have more than 500 MW of coal

fired capacity either planned or installed. These owners will be

buying components and systems for 500,000 MW of new coal fired generators

and replacement and upgrade components for 2.2 million MW of existing capacity.

These companies will purchase more combust, flow and treat products than

owners of nuclear, solar, gas turbine, and wind generators combined. These

plants are moving toward centralized purchasing based on lowest total

cost of ownership. Therefore sales programs directed to each of

the 1000 companies will be highly productive and cost effective. The

Utility E Alert 41F

Utility E-Alert reports on

the projects and technology on a weekly basis. This is part of the

Utility Tracking System 42EI

Utility Tracking System with

details on each plant.

Here is an

example of those coal fired plant operators with planned additions between

6000-7000 MW.

|

Company

|

Planned MW

|

Installed

MW

|

|

NLC

India

|

6,700

|

3,990

|

|

TANGEDCO

|

6,640

|

4,320

|

|

J-POWER

|

6,356

|

8,482

|

|

Eskom

|

6,352

|

41,129

|

|

UPRVUNL

|

6,270

|

5,474

|

|

GCM

Resources

|

6,000

|

0

|

The tracking

system also provides forecasts of coal fired capacity by country through

2024.

|

Coal Fired Capacity- MW

|

|

Country

|

2018

|

2019

|

2020

|

2021

|

2022

|

2023

|

2024

|

|

Romania

|

5,305

|

5,305

|

5,305

|

5,305

|

5,305

|

5,305

|

6,000

|

|

Slovakia

|

881

|

881

|

881

|

881

|

881

|

881

|

881

|

|

Bosnia &

Herzegovina

|

2,073

|

2,073

|

2,073

|

2,073

|

2,073

|

3,000

|

4,000

|

|

Serbia

|

4,405

|

4,405

|

4,405

|

4,405

|

4,405

|

5,000

|

5,000

|

|

North Macedonia

|

800

|

800

|

800

|

800

|

800

|

800

|

1,200

|

|

Slovenia

|

1,069

|

1,069

|

1,069

|

1,069

|

1,069

|

1,069

|

1,069

|

|

Croatia

|

210

|

210

|

210

|

210

|

210

|

210

|

210

|

For more

information on the tracking system click on 42EI

Utility Tracking System.

Bob McIlvaine can answer your questions at rmcilvaine@mcilvainecompany.com cell 847 226 2391

The Future of Biopharmaceuticals will

Depend on Perceived Value vs Cost

The National

Institute for Health and Care Excellence (NICE)

in the U.K has approved several CAR-T therapies even though the cost may be

hundreds of thousands of dollars. The rationale is that the benefits will

be long lasting and result in average costs per Quality Adjusted Life Year

(QALY) gained which are within the guidelines.

NICE says it generally considers that

interventions costing the National Health Service (NHS)

less than £20,000 per QALY gained are cost

effective and those costing up to £30,000 per QALY gained might, with

certain conditions satisfied, be considered cost effective.

The biopharmaceutical industry is

making rapid progress to develop drugs to cure or mitigate diseases.

However, this progress is coming with increased costs.

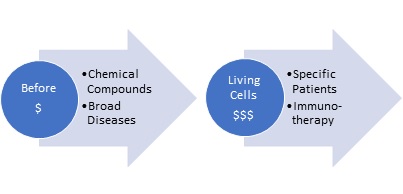

Costs

increased as the healthcare industry expanded from using chemical compounds

and treating broad diseases to utilizing living cells and creating drugs

for specific individuals with CAR-T and other therapies. Even if there is

no increase in the cost reimbursement per QALY, new medicines will increase

the number of people who will benefit.

This results

in a steadily increasing cost of healthcare as a percentage of GDP. This

will require tougher decisions about

how care is allocated. The optimum program should take into account

1

A

more useful definition than QALY

2

The need to allocate health care

expenditures as part of a broader

program to maximize life quality

3

Integration

of two additional metrics

a.

Discounted

future value

b.

Tribal

factor

A more useful

definition than QALY

QALY is widely

used around the world to determine the cost/benefits of treatment. One year of perfect health

equals one QALY. One year of less than perfect health has a quality of life

(QoL, or utility value) between 0–1. Death has a utility value of 0 (a

respondent could choose to record a score below zero – worse than death –

where, for instance, they are experiencing severe distress and/or possibly

a terminal illness).

QoL has five

dimensions: mobility, self-care, usual activities, pain/discomfort and

anxiety/ depression, each of which can be at one of three levels of

severity, for example: no problems, some/moderate problems and extreme

problems. A new five-level version can describe 243 unique combinations.

The problem

with QALY is that the definition of perfect is far below the aspirations of

anyone. A prisoner in solitary

confinement could be higher on the

list for a heart transplant than most individuals. The solider who falls on the grenade has

elevated one minute of life quality above decades of life quantity. The

average person would rather live to 80 and enjoy life than live to 100

without ever experiencing life’s more risky pleasures.

There is a

metric which is better than QALY and will have common acceptance. It is Quality Enhanced Life Days (QELD).

It simply quantifies the decisions people have made and are making to

improve their life quality.

The need to

allocate health care expenditures as part of a program to maximize life

quality. With all the new therapies there is a real

value in continuing to increase expenditures as a percentage of GDP. This

decision can be best made by using QELD as a common metric to decide how

expenditures are allocated. An example would be climate change vs healthcare.

There is a world wide movement for a very expensive program to reduce CO2

emissions. What share of GDP should go to fight climate change versus

medical treatment? QELD can be the

metric to best make this decision.

Integration of

Two Additional Metrics

QELD has to be

determined based on the intrinsic

value but with these additional metrics. One is the discounted future

value. A medical treatment may have immediate benefits whereas investment

in programs to decrease greenhouse gases may not have tangible benefits for

many decades. The other metric is the tribal factor. Most people prioritize

family life quality followed in descending order by friends and neighbors,

city, and finally country. The lower concern for individuals in other countries is reflected in the foreign aid budgets of

wealthy nations. It is typically far less than 1% of GDP.

McIlvaine has

provided in depth analysis of the use of QELD, discounted future value, and

the tribal factor in its consulting activities. Cardinal Health contracted

with McIlvaine to help them determine whether they should be offering

single use or reusable surgical gowns. Single use surgical gowns are

discarded and replaced adding to the world’s CO2 burden. Washing and

reusing gowns provides risks of waterborne disease.

The analysis

concluded that the quantity of CO2 emitted from manufacturing 17 million

gowns per year was miniscule as was the risk of water borne disease from

reusables. The difference for hospital patients living near the hospital

was that the washing risks would be

immediate and would affect them whereas

the greenhouse gas risks were long term and unlikely to affect them

as much as it would those living near the equator.

More

information on this study is shown at

Sustainability Universal Rating System An article on the

subject was featured in

https://www.healthcaredevelopmentmagazine.com/article/quality-enhanced-life-days-a-new-metric-for-hospital-sustainability.html.

For more information on this initiative contact Bob McIlvaine at rmcilvaine@mcilvainecompany.com

cell 847 226 2391

Click here

to un-subscribe from this mailing list

|