The Sterile Filtration of Beer - Keeping up with Consumer Trends

Posted by Food Beverage Filtration Team on Wednesday, May 16, 2018

The Sterile Filtration of Beer - Keeping up with Consumer Trends - Beverages -

Parker Bioscience

Some of the world’s largest breweries have recently reported a decline in sales

as they have admittedly failed to amend their brand portfolio to meet consumer

trends. Sterile filtration could be the key to adapting to these changes to

consumer behaviour.

Changing consumer trends

Modern beer drinkers are moving away from the traditional big brands and opting

for increasingly sophisticated drinks such as craft beers. As a result, large

breweries are experiencing a decline in sales, losing their market share to

smaller breweries who are more on target with consumer preferences.

In an effort to regain market share, breweries are aiming to remodel their

brands in order to appeal to the modern consumer. They have begun adapting to

these changes through acquisition of popular craft breweries and marketing some

of their brands as a more premium product, in an attempt to appeal to the

sophisticated beer drinker.

Breweries of all capacities are beginning to realise that in order to protect

their bottom line profits in such a competitive market they must amend their

production process and fundamentally seek to produce higher quality beer at

optimum cost efficiency.

Process optimisation

The process of microbial stabilisation is an essential stage of all beer

production, without which the product may succumb to spoilage due to bacterial

contamination before it can be consumed. This process is typically achieved by

one of a few methods: good sterile practice, tunnel pasteurisation, flash

pasteurisation or sterile filtration.

Good sterile practice cannot guarantee complete product sterility and may result

in huge product losses due to human error or environmental contamination

regardless of protocols followed.

Furthermore, tunnel pasteurisation is an out-dated method, which consumes

enormous quantities of thermal energy, and is not always guaranteed to kill all

suspended bacteria.

Today, therefore, the two primary methods of microbial stabilisation are flash

pasteurisation and sterile filtration. However, the brewing industry is shifting

away from flash pasteurisation as they discover the significant advantages to

both operating costs and overall product quality of sterile filtration over

flash pasteurisation.

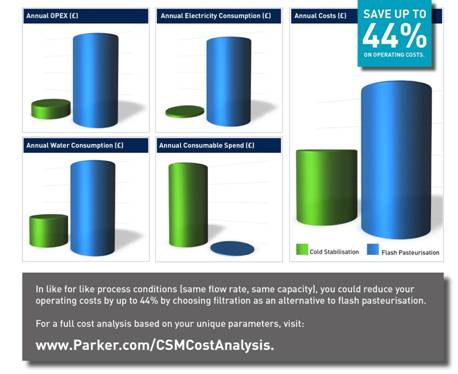

Reducing costs and increasing flavour to meet consumption trends

The recent partnership between Parker and Agidens automation – experts of both

automated sterile filtration modules and flash pasteurisation systems, have

enabled Parker Bioscience to establish a comparison of the operating costs of

flash pasteurisation vs sterile filtration using Parker's BEVPOR BR range of

microfilter cartridges. The research measured the annual electricity

consumption, the annual water consumption and the annual consumable spend of

both sterile filtration and flash pasteurisation processes. The results

concluded that these combined factors proved sterile filtration to be the most

cost-effective method of microbial stabilisation, saving brewers up to 44% of

their annual operating costs when compared to flash pasteurisation. Parker

Bioscience offers a free full-cost analysis based on your breweries specific

parameters, which can determine the cost savings of sterile filtration compared

to your current method of microbial stabilisation.

The Sterile Filtration of Beer - Keeping up with Consumer Trends_Cost

Analysis_Parker Bioscience