| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Controlled Closure Check Valve .

Controlled Closure Check Valve .

|

|

|

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

|

| |

1.Function |

| |

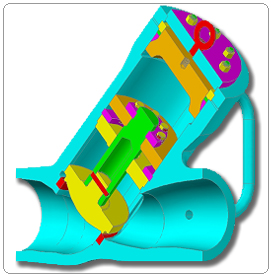

The Controlled Closure Check Valve

was developed and qualified to serve a function to control the |

| |

valve closing velocity.If a

feed-water line should rupture in a nuclear power plant, the reversed |

| |

flow from the steam generator out of

the containment boundary must be contained. |

| |

Swing check valve would close

rapidly, but not fast enough to prevent high reverse flow velocity;

|

| |

closure of the swing check valve

would produce severe pressure surges due to water hammer - |

| |

possibly severe pressure enough to

produce rupture of other piping or equipment. |

| |

|

| |

The Controlled Closure Check Valve is

similar to Y-pattern Lift check vavle, but it has an |

| |

integral "dash-pot" - a battle plate

with a close-clearance fit around the rod connecting the disc |

| |

and piston. Flow paths sized for and

consequently control the valve closing speed. |

| |

|

| |

2. Characteristics |

|

- Minimizes water hammer effects on

postulated feed-water line break. |

|

- Computerized modeling verified by

dynamic testing. |

| |

|

|

|

|

| |

|

|

|

|

| |

|

|

|

|

|

| |

|

|

|

|

|

| |

|

|

|

|

|

| |

|

|

|

|

|

| |

|

|

|

|

|

| |

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Butterfly Valve for Nuclear Power Plant.

Butterfly Valve for Nuclear Power Plant.

|

|

|

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

| |

|

| |

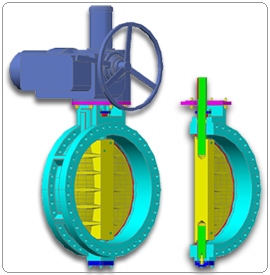

1.Design characteristics |

| |

- Valve Size : 2" through 48" |

| |

- Valve Rating : Class 150 |

| |

- Application Code : ASEM B16.34 &

ASME Sec. Ⅲ |

| |

- Seismic Rating : Category

Ⅰfor active and

non-active service. The upset emergency or faulted |

| |

conditions

will be analyzed concurrently with 5g seismic load applied simultaneously

along three |

| |

major axes. The stress levels code

allowable. |

| |

- Qualification : Performed

functional qualification test per ASME QME-1 |

| |

|

| |

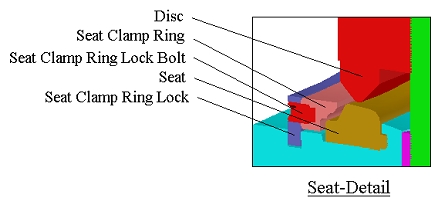

2.Seat Characteristics |

| |

- Sealing is achieve by elastically

deforming the seat. |

| |

- Seat design offers the advantage of

being easily replaceable in the field. |

| |

- Mechanically retained on the disc ;

adjustable with access from flanged end of the valve |

| |

|

| |

| |

| |

| |

| |

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

|

|

|

|

| |

|

|

|

|

|

| |

|

|

|

|

|