|

|||||||

|

|

|||||||

|

· “Coal-fired Boiler Optimization” is “Hot Topic” on Sept. 27 and Oct. 11, 2012

· McIlvaine Hot Topic Hour Registration

· Headlines for the September 28, 2012 – Utility E-Alert

· World Needs to Efficiently Utilize Its Finite Coal Reserves

· The Good and the Bad News about Wind Energy

“Coal-fired Boiler Optimization” is “Hot Topic” on Oct. 11, 2012

In order to accommodate the number of persons that desired to make a presentation on this subject and keep the Hot Topic Hour within a reasonable time, we split it into two sessions – the first on Thursday, Sept. 27, 2012 at 10 a.m. Central time and the second on Thursday, Oct. 11, 2012 at 10 a.m. (Central time). Persons that register for the first session will automatically be registered for the second session at no additional cost.

Boiler operators have always been interested in improving the efficiency of their operations to reduce cost but today they are looking at efficiency improvements as part of the solution to some of the other concerns they are faced with. Improving efficiency of the combustion process and heat recovery of only a few percent can save hundreds of thousands of dollars in fuel and other material costs. Improving boiler efficiency will also reduce the total CO2 emissions and help to meet the new regulations for GHG reduction being imposed by states and soon the U.S. EPA as well as reduce emissions of other criteria pollutants.

Executives are increasing asking utility engineers questions regarding boiler efficiency improvement such as: What are the available systems, technologies and methods for improving efficiency and who provides them? Have these systems, technology and methods been proven in other plants with the same configuration as mine? What is the impact on maintenance and overall operating cost? Is there a tradeoff between cost and reductions in emissions? What is the best way to improve efficiency or where will we get the best bang for the buck, so to speak? Should we invest in optimization software and/or additional monitoring instrumentation?

The following speakers will help us understand the process of improving boiler efficiency; how to obtain optimum efficiency, availability and performance; describe the technologies available and under development with their applicability, capabilities and limitations; costs involved and the benefits that can be attained and describe their real world experience with improving the operating efficiency of fossil-fueled power plant boilers.

The speakers on Thursday, October 11, 2012 will be:

Keith Moore, President of Castle Light Energy Corporation

Ati Manay, PMP, P.E., Product Manager of “SMART Clean” at Clyde Bergemann Power Group Americas, will discuss “On Load Boiler Cleaning Optimization Technologies and its Integration into Boiler Back End Equipment Temperature Control.” His presentation will include:

• Review of best available On Load Cleaning Optimization Technologies, SMART Feedback Devices, and their integration into different optimization goals for the power boilers.

• Case study on tube life and reliability optimization

• Case study on SCR temperature control

• Case study on Plant Heat Rate Optimization

• Case studies on Fuel Flexibility

Stephen Storm, Principal and Owner of both Stephen Storm, Inc. and SX Powertech, LLC, will present “Inter-relationships of Combustion, Efficiency, Reliability & Air Pollution Control.” When assessing the inter-relationships of combustion, efficiency, reliability and air pollution, the evaluation must be "holistic" and comprehensive in nature. The control of combustion and heat transfer with large steam generators is contingent upon how well the fuel, air and flue gas is distributed, while also managing the combustion byproducts. Then, the performance and reliability of the air pollution control equipment is subject to the quality and volume of gas being treated. With that being said, the purpose of this presentation is to share experiences, observations and industry challenges.

To register for the Hot Topic on Thursday, Oct. 11, 2012 at 10 a.m. (Central time), click on:

http://www.mcilvainecompany.com/brochures/hot_topic_hour_registration.htm.

McIlvaine Hot Topic Hour Registration

On Thursday at 10 a.m. Central time, McIlvaine hosts a 90 minute web meeting on important energy and pollution control subjects. Power webinars are free for subscribers to either Power Plant Air Quality Decisions or Utility Environmental Upgrade Tracking System. The cost is $125.00 for non-subscribers.

Market Intelligence webinars are free to McIlvaine market report.

|

|

2012 |

|

|

DATE |

SUBJECT |

|

|

September 27 |

Coal-fired Boiler Optimization – Part 1 |

Power |

|

October 11 |

Coal-fired Boiler Optimization – Part 2 |

Power |

|

October 18 |

Air Preheaters & Heat Exchangers |

Power |

|

October 25 |

Instrumentation for air, gas, water, liquids (forecasts, market shares, growth segments). |

Market Intelligence |

|

November 1 |

Cooling Towers and Cooling Water Issues |

Power |

|

November 8 |

FGD Scrubber Components |

Power |

|

November 15 |

Dampers and Expansion Joints for Coal-fired and Gas Turbine Power Plants |

Power |

|

November 29 |

Catalyst Selection for NOx and Other Gases |

Power |

|

December 6 |

Boiler Feed and Cooling Water Treatment |

Power |

|

December 13 |

Co-firing Sewage Sludge, Biomass and Municipal Waste |

Power |

|

|

2013 |

|

|

January 10 |

Update on Oxy-fuel Combustion |

Power |

|

January 17 |

Production of Fertilizer and Sulfuric Acid at Coal-fired Power Plants |

Power |

|

January 24 |

Gypsum Dewatering |

Power |

|

January 31 |

Filter media (forecasts and market drivers for media used in air, gas, liquid, fluid applications, both mobile and stationary). |

Market Intelligence |

|

February 7 |

Valves for Power Plants, Boilers and Water Treatment Facilities |

Power |

To register for the Hot Topic Hour, click on:

http://www.mcilvainecompany.com/brochures/hot_topic_hour_registration.htm.

Here are the Headlines for the September 28, 2012 – Utility E-Alert

UTILITY E-ALERT

#1094 – September 28, 2012

Table of Contents

COAL – US

COAL – WORLD

GAS/OIL / US

GAS/OIL WORLD

BIOMASS

NUCLEAR

BUSINESS

HOT TOPIC HOUR

For more information on the Utility Environmental Upgrade Tracking System, click on: http://www.mcilvainecompany.com/brochures/energy.html#42ei.

World Needs to Efficiently Utilize Its Finite Coal Reserves

The world’s supply of fossil energy is finite and must be utilized in the most economically and environmentally beneficial manner. This dictates construction of coal-fired power plants where enhanced oil recovery (EOR) provides a use for CO2. In parallel gas which would otherwise be used for power generation in the EOR areas is converted to LNG and liquids and used in other regions. Also in parallel large energy consuming industries expand in EOR areas such as the U.S. and Middle East/Africa. This is the conclusion reached by the McIlvaine Company in its report, Fossil & Nuclear Power Generation: World Analysis & Forecast, click on: http://www.mcilvainecompany.com/brochures/energy.html#n043.

Coal is one of the world’s most valuable energy resources. Over the next century it will all be consumed along with the remaining gas and oil. In the twenty second century, fossil fuels will not be available and we will have to solely depend on nuclear, solar, wind, biomass and other renewable resources. In the meantime, we need to utilize the fossil resources most appropriately. Each of the fossil fuel resources has unique uses and advantages. Here are the advantages of coal:

· Coal is the lowest cost fuel for power generation.

· Coal is the cheapest source of CO2 for enhanced oil recovery

· Clean Coal technology can deliver any cleanliness needed.

· A coal-fired boiler with 20 percent biomass and 80 percent coal with 90 percent CO2 capture is a net reducer of greenhouse gases

The potential to utilize coal most efficiently would result in:

· Greater gas utilization for residential heating and chemicals production

· Extend the date at which biomass becomes the only source for plastics and organic chemicals

The plan to make this happen must be global and take into account all the long-range environmental and economic consequences. There are a number of facts which are often overlooked but are important to the initiative:

· The economic life of a coal-fired power plant need only be twenty-five years

· Enhanced oil recovery makes coal-fired generation green and economically attractive

· The cost to transport coal long distances by ship is less than to transport it short distances by rail

· Large energy consumers such as aluminum smelters will be built where energy costs are the lowest

· Energy complexes greatly increase energy efficiency and make use of the heat otherwise wasted in the visual steam plume from the cooling tower

· Gas can be economically transferred long distances if converted to LNG or liquids

· Greenhouse gases are a global problem and require a global solution

Background

It has been estimated that there are over 847 billion tons of proven coal reserves worldwide. This means that there is enough coal to last us around 118 years at current rates of production according to the World Coal Association. In contrast, proven oil and gas reserves are equivalent to around 46 and 59 years at current production levels.

The coal demand in Asian countries is soaring. McIlvaine projects 2700 GW of coal-fired capacity in the world in 2017. This could rise at 3%/yr to 3970 GW by 2030. At this rate, the world only has a eighty year supply of coal Advanced Resources International estimates that there is the potential through enhanced oil recovery to create an additional 500 to 1000 billion barrels of oil and to store 320 billion metric tons of CO2 at the same time.. This storage would accommodate 4300 GW of coal-fired capacity for forty years.

The U.S. could store 34 billion tons of CO2. Canada and Mexico could utilize and store another 9 billion tons. This is enough to sequester all the coal-fired power CO2 generation for 25 years.

The biggest potential (125,000 billion tons) is in the Middle East and North Africa. The Asia–Pacific region would have a need for only 8 billion tons of CO2.

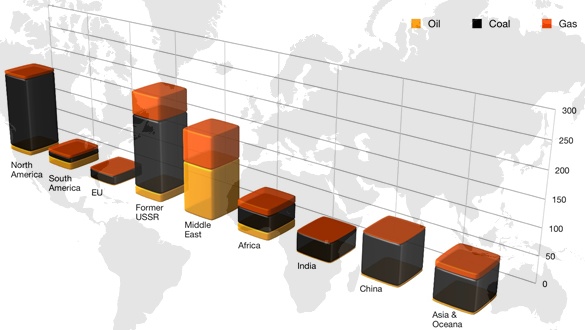

Proven Reserves of Oil, Coal and Gas

(Figures from World Coal Association)

World Energy Council estimates of proved recoverable reserves (hard coal and lignite) at end-2008 (Billion Metric Tons) such as the U.S. and Middle East/Africa.

|

Region |

Recoverable Reserves |

Share of Recoverable Reserves |

|

US and Canada |

243.9 |

28.3% |

|

Russian Federation |

157.0 |

18.2% |

|

China |

114.5 |

13.3% |

|

Europe (incl. Turkey) |

110.4 |

12.8% |

|

Australia |

76.4 |

8.9% |

|

India |

60.6 |

7.0% |

|

Kazakhstan |

33.6 |

3.9% |

|

South Africa |

30.2 |

3.5% |

|

All Other |

34.3 |

4.0% |

|

World Total |

860.9 |

100% |

For more information on: Fossil & Nuclear Power Generation: World Analysis & Forecast, click on: http://www.mcilvainecompany.com/brochures/energy.html#n043.

The Good and the Bad News about Wind Energy

There’s much good news being reported about wind power – job creation, economic benefits to communities and of course reduced emissions. At the same time in the United States the potential end of the Production Tax Credit (PTC) is putting a damper on growth in the wind industry. McIlvaine’s Renewable Energy Projects and Update keeps readers up to date on the industry.

American Wind Power Reaches 50 GW Milestone

American Wind Power has blown through an historic milestone: 50 gigawatts of electric generating capacity, the American Wind Energy Association announced, just as Congress works to extend a critical federal policy and continue the growth of wind power in the U.S.

The 50 GW online today means that U.S. wind turbines now power the equivalent of nearly 13 million American homes — or as many as Nevada, Colorado, Wisconsin, Virginia, Alabama and Connecticut combined. In addition, 50 GW of wind power capacity:

Each major wind farm in America creates nearly 1,100 jobs and can add tens of millions of dollars in new taxes and other benefits to the communities where they're located, according to two new reports from the Natural Resources Defense Council.

A new 250-megawatt wind farm will create 1,079 jobs throughout the many steps of building that wind farm, according to the NRDC report "American Wind Farms: Breaking Down the Benefits from Planning to Production." These are positions in manufacturing, construction engineering and management, among other areas.

But the benefits don't end there, a separate NRDC study on the secondary impacts of the wind energy industry shows.

Wind farms also are helping revitalize communities across the country by generating new taxes, lease payments to landowners and economic development revenues, in addition to creating new job opportunities, the NRDC report "At Wind Speed: How the U.S. Wind Industry is Rapidly Growing Our Local Economies," shows. The report profiles four communities from Ohio to Oregon that have benefitted from the wind industry.

Non-construction businesses account for an estimated 557 jobs. They include 432 workers in manufacturing, 80 in planning and development, 18 in sales and distribution and 27 in operations and maintenance.

Construction jobs add another 522 jobs to a typical wind farm. These workers are spread between three categories, with 273 working on on-site civil works, such as roads, and foundations; 202 working on the installation of the wind turbines and 47 working on on-site electrical work, such as grid connection.

Additionally, the report profiles American companies that could participate at every one of the 14 steps of the wind farm.

New UK Research Proves Economic Benefits of Onshore Wind

The benefits of onshore wind to both local economies and to UK PLC has been revealed by findings of a report published by RenewableUK and the Department for Energy and Climate Change (DECC).

The report, by BiGGAR Economics, looks at 18 case studies of wind farms of different sizes drawn from across the UK. It analyses the contribution of wind farm development, construction, operation and maintenance to the UK economy at a local, regional and national level.

The report finds that onshore wind supported 8,600 jobs and was worth £548 million to the UK economy in 2011. Of this figure 1,100 jobs were created at the Local Authority level, worth £84 million.

If onshore wind is deployed at a scale suggested in the Government’s Renewable Energy Roadmap, the economy could benefit to the tune of £0.78 billion by 2020, supporting around 11,600 jobs.

New Report Shows Wind Power is Reliable and Reduces Emissions

A new report published by renewable energy consultancy GL Garrad Hassan and the Institute for Public Policy Research (IPPR) shows how wind power can provide reliable, economic and secure energy generation capacity for the United Kingdom. The report, titled “Beyond the Bluster”, examines common misconceptions about the effectiveness of wind power.

It contains analysis of electricity system operation and international wind energy experience to show that wind power is a potent means of reducing power sector CO2 emissions; and, wind power can provide a significant proportion of the UK’s electricity needs with little impact on system operation or security.

These important issues are often misrepresented by those critical of wind power. Head of Strategy & Policy at GL Garrad Hassan Joe Phillips said: “A report that shows wind power to be effective should not be news. But misinformation about the technology has created confusion and this report is part of our efforts to present the technical evidence — so people can make up their own minds. The message we want to communicate to the public is clear: claims that wind power is ineffective are not supported by the evidence. Making good energy policy is difficult and there are many challenges. But one thing we can be sure of is, of all the factors influencing the development of the UK’s energy system, the ability of wind power technology to contribute positively to that development is one of the things we can be completely confident in.”

The report is published against the backdrop of heated political debate about the future of the UK energy sector, including comprehensive reform of the electricity market. Reg Platt, Research Fellow at IPPR said: “Energy policy should be determined on the basis of evidence and not by political whim. The facts are clear: wind power is an effective technology that can produce beneficial outcomes for both UK consumers and the UK economy. There is a lot of unfounded bluster out there on wind power. We need to rise above this and stick to the facts, so that we don’t squander the economic opportunities that this important technology can provide.”

Citing the need to recruit and train a larger, educated workforce to support the global expansion of renewable energy, GE and Excelsior College announced that GE employees can receive up to nearly 50 college credits from the college for completing the company’s intensive renewable energy services training program.

To earn GE’s Lead Certification Standard, technicians must complete more than 500 hours of classroom, online and practical, hands-on field training on wind turbine components at GE’s Energy Learning Center (ELC) in Schenectady, N.Y., where GE’s renewable energy business is headquartered.

At the ELC, technicians are trained—with a strong focus on safety—to inspect and repair actual GE wind turbine components, including the nacelle, which is installed atop a 200-foot steel tower and houses the wind turbine’s generating equipment.

Technicians who complete the certification program now are eligible to earn up to 49 credit hours for their work experience through Excelsior College, the leading nonprofit, regionally accredited distance education institution in the nation.

Excelsior College has created a new concentration in Renewable Energy Technologies within the school’s Bachelor of Professional Studies in Technology Management program.

For more information on Renewable Energy Projects and Update please visit

----------

You can register for our free McIlvaine Newsletters at: http://www.mcilvainecompany.com/brochures/Free_Newsletter_Registration_Form.htm.

Bob McIlvaine

President

847 784 0012 ext 112

rmcilvaine@mcilvainecompany.com

www.mcilvaine@mcilvainecompany.com

Copyright © 2012 McIlvaine Company. All Rights

Reserved

191 Waukegan Road Suite 208 | Northfield | IL 60093

Ph: 847-784-0012 | Fax; 847-784-0061

Click here to un-subscribe from this mailing list