|

||||||||||||||

|

||||||||||||||

|

||||||||||||||

|

||||||||||||||

· Optimize Combustion by Balancing Coal Pipes and Controlling Burner Air/Fuel Ratios

· On September 22, 2011 “Hot Topic Hour” “Dry FGD: Spray Dry vs. CFB vs. DSI”

· Headlines for the September 9, 2011 – Utility E Alert

· Unique Renewable Energy Applications

Optimize Combustion by Balancing Coal Pipes and Controlling Burner Air/Fuel Ratios

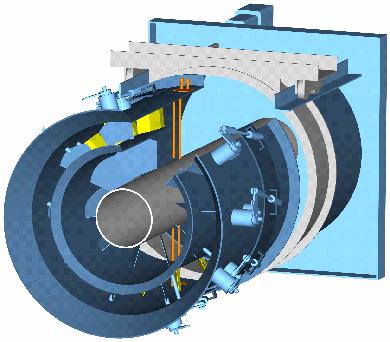

….Next Wednesday, September 21 at 10 a.m. there is a free hot topic webinar on optimization. Dave Earley from AMC Power will discuss how the continuous measurement of and the control of burner line coal flows can improve combustion. The continuous measurement of the coal particle velocities can also help improve flame stability and PA control and, thus, help improve NOx, LOI, slagging/fouling, coal layout and more:

![]()

![]()

…When combined with the AMC IBAMS for online measurement and control of burner SA, air/fuel ratios can be more tightly controlled to help reduce CO, improve O2 distribution and thus improve NOx and boiler efficiency.

You can register for this free webinar at: http://www.mcilvainecompany.com/brochures/hot_topic_hour_registration.htm.

----------

On September 22, 2011 “Hot Topic Hour” “Dry FGD: Spray Dry vs. CFB vs. DSI”

On September 22, 2011 at 10 a.m. CDT, the McIlvaine Company “Hot Topic Hour” will feature a Panel Discussion on “Dry FGD: Spray Dry vs. CFB vs. DSI”. Six expert panelists will address the following questions:

1. Which dry technology is best for my situation – Spray Dry, CFB or DSI?

2. Will this system meet the coming SO2 and future particulate limits?

3. What is the relative efficiency (percent removal) with coals of different sulfur content or how much flexibility do I have with fuel selection?

4. How effective is the technology in also removing Hg and other heavy metals, HCl, HF and SO3?

5. What are the relative capital and lifetime operating costs?

The panelists are:

David W. South, Manager, Business Development, Amerex Industries, Inc.

Travis Vaughn, Manager/Business Development, FMC Corporation

John Toher, IJM Consultants

Michael James Widico, Vice-President, Business Development/APC, Lodge Cottrell

Lew Benson, SO2 Group Leader, Nalco/Mobotec

Keith C. Day, Director, Business Development, Duct Injection, United Conveyor DSI, LLC

To register to attend this event click on: http://www.mcilvainecompany.com/brochures/hot_topic_hour_registration.htm.

----------

Here are the Headlines for the September 9, 2011 – Utility E Alert

UTILITY E-ALERT

#1041– September 9, 2011

Table of Contents

COAL – US

COAL – WORLD

GAS / OIL - US

GAS / OIL – WORLD

BIOMASS

NUCLEAR

BUSINESS

HOT TOPIC HOUR

For more information on the Utility Environmental Upgrade Tracking System, click on: http://www.mcilvainecompany.com/brochures/energy.html#42ei.

----------

Unique Renewable Energy Applications

The McIlvaine Company is reporting on new and unique ways to apply renewable energy in each of our Renewable Energy Updates. Here are just a few recent examples.

Carlisle Energy Services, Inc. (CES) announced that as of Wednesday, August 17, 2011, its Spectro PowerCap™ Exposed Geomembrane Solar Cover system in Madison County, New York is complete. The eight-acre demonstration system features Carlisle's GeoTPO™ Geomembrane, with a south-facing 40kWp DC integrated solar photovoltaic array powered by Uni-Solar®. Carlisle's system is expected to offset nearly all of the power requirements of the Madison County ARC Recycling Facility located on site.

The Madison County landfill is the first municipal landfill in the country to apply this technology in a closure project. Future plans for the site, referred to as the Madison County Agriculture and Renewable Energy Park, include a one-megawatt landfill gas system that captures the heat generated by the turbine engines to dry lumber on site and heat the building. Other on-site green energy programs are being considered such as the possibility of adding a windmill, hydroponic greenhouses, and/or an additional solar array.

*****

Southwest Solar Technologies Inc. announced the successful on-sun testing and proof of concept of a highly advanced solar-turbine power system being developed by the Company. The full-scale prototype test was the first operational validation of the integrated system, which uses a large parabolic solar dish with mirrors to concentrate the sun’s energy to power an air-based open cycle turbine to produce electricity.

This milestone field test was conducted in Phoenix using the Company’s 320-square-meter solar concentrating dish, the largest solar dish in North America. The dish delivered thermal energy in the form of 2000 “suns” of concentrated sunlight into its advanced high-temperature solar thermal receiver. Inside this receiver compressed air was superheated, and that superheated air was used to power a high-speed turbine alternator and produce electrical power.

****

Konarka Technologies, Inc., an innovator in development and commercialization of Konarka Power Plastic®, a lightweight, flexible material that converts light to electricity, announced the company is working with the Color/Construction Unit of ThyssenKrupp Steel Europe, a leading supplier of steel construction elements in Germany, to develop steel roof and other construction elements for building-integrated photovoltaics (BIPV). The joint solar solution will be based on Konarka’s Power Plastic which easily replaces conventional building materials in roofs, skylights and facades.

“Konarka’s thin, light and flexible photovoltaic technology will be applied to our substrate materials in a continuous process, both cost-efficiently and eco-friendly, ideally integrating into our production process,” commented Dr. Lars Pfeiffer, head of quality and development at the Color/Construction unit. “Unlike conventional silicon-based photovoltaic systems, the joint solar solution will not need to be mounted on a raised structure but will integrate smoothly into the building envelope.

During ThyssenKrupp Steel Europe’s production process, the steel strip is coil coated with films, paint or plastic coatings. These continuous coating lines will be used to apply Konarka’s organic photovoltaic surface. Available in various colors, color combinations and sizes, the construction elements with Konarka’s Power Plastic will give planners and architects a great deal of design latitude.

*****

Kyocera Corporation announced that it has supplied its high-performance solar modules for a carport roofing installation in southern Germany which provides power for a charging station for electric cars and bikes. The system was designed and installed by BLU"e" Solar Group GmbH.

Electric-powered automobiles and bicycles are becoming increasingly popular in Germany as they provide a convenient and eco-friendly method of transportation. As a result, there is a growing need for charging stations to meet increased use. Furthermore, this solar-powered charging station is not only environmentally friendly but also economical; currently, charging at this location is free of charge to the public. The energy used to 'fill the tanks' comes from 248 high-efficiency 215-watt Kyocera solar modules which produce an output of 53.32kW.

*****

Installing Emergency Assistance Stations (EAS) and surveillance cameras in remote and difficult locations can be costly, time-consuming and disruptive. Yet it is these areas that oftentimes benefit most from the added safety of these security elements — connecting students on playfields to campus security, employees in parking lots to security personnel and trail users to the nearest emergency responder. Now available, Solar Secure is the first solar-powered security product designed to enable the deployment of EAS and cameras with renewable, redundant energy sources and wireless communications.

Solar Secure generates all of the energy it needs to power its components and the associated EAS from solar panels. Hydride fuel cells are also included as a backup power source. Because it is net zero energy and operates via wireless communications, installation does not require trenching or extensive site preparation.

For more information on Renewable Energy Projects and Update please visit

----------

You can register for our free McIlvaine Newsletters at: http://www.mcilvainecompany.com/brochures/Free_Newsletter_Registration_Form.htm.

Bob

McIlvaine

President

847 784 0012 ext 112

rmcilvaine@mcilvainecompany.com

www.mcilvaine@mcilvainecompany.com

Copyright ©

2011 McIlvaine Company. All Rights Reserved

191 Waukegan Road Suite 208 | Northfield | IL 60093

Ph: 847-784-0012 | Fax; 847-784-0061

Click here to un-subscribe from this mailing list