|

·

How

to Increase Sludge Dryness (Answers at WEFTEC)

·

Sludge Dryness WEFTEC Route Map in GDPS will be Updated, Expanded

and Sent to you Again Next Week

·

Sludge Dryness GDPS Route Map will be Permanent

·

Some WEFTEC Highlights

·

Additional Highlights will be added Next Week

How to Increase

Sludge Dryness (Answers at WEFTEC)

WEFTEC will start

on October 5 and close on October 9. McIlvaine, as usual will be

interviewing exhibitors and speakers. However, a new concept will

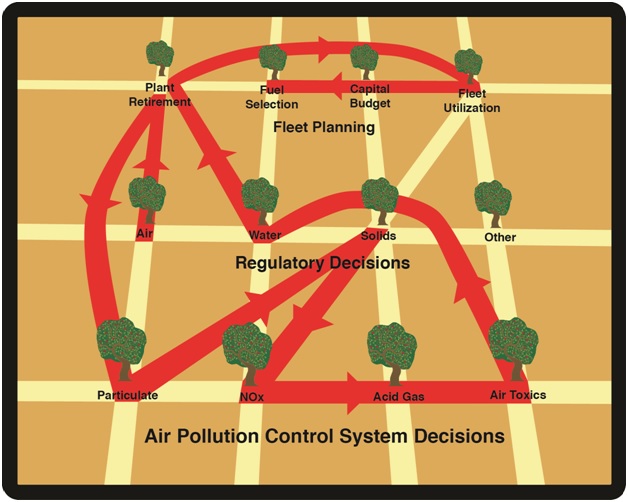

also be introduced. This concept is called the Global Decisions

Positioning SystemT (GDPS). The template is the

McIlvaine Power Plant Air Quality Decisions. This system has been

continuously honed since it was introduced in 1974. Now the concept

is being applied to many other areas including municipal secondary

wastewater treatment. The concept is explained at;

Global Decisions

Positioning SystemT (GDPS)

Global

Decisions Orchard Global

Decisions Orchard

Each system has a

sector in the Global Decisions Orchard. Many decisions require

travel through a number of decision trees. GDPS provides the route

maps. Secondary wastewater treatment requires thousands of decisions

and, therefore, thousands of route maps, so achieving drier sludge

is just one of them.

Secondary Wastewater Treatment Orchard Sector

Wastewater plants

are continually seeking to reduce energy costs through more

efficient operations. Drier sludge is one potential.

Drier Sludge Route Map in Secondary Wastewater

Treatment GDPS

Many plant

operators and consultants attending WEFTEC will be focused on

improving the efficiency of their plants. Reducing aeration energy

with variable speed drives or more efficient blowers may be an

option to be investigated. Automating operations would also be

attractive. Energy recovery by generating biogas would be another. A

fourth option would be obtaining a drier sludge to reduce

incinerator fuel consumption.

Each opportunity

needs to be investigated separately. We have chosen the drier sludge

on which to focus instead of spending hours determining which

speeches, posters and stands will provide insights on each aspect of

the investigation. The visitors can use the equivalent of your

automobile GPS. The advantage will be as significant as the GPS

system in the vehicle vs. the map provided at the rental counter.

To investigate

ways to obtain greater sludge dryness, it makes sense to first see

whether there are some operating initiatives which will achieve the

improvement.

1st

Decision Tree Stop: Chemicals for final dewatering 1st

Decision Tree Stop: Chemicals for final dewatering

The simple

solution would be to change the chemical additions prior to the belt

press in some way to improve the final dryness.

Speeches and Posters:

Monday

10:30 a.m. - Booth 2613 BASF Solutions for Global Water Challenges,

by Linda Muroski, Business Director, Water Solutions North America,

BASF

11:00 a.m. -

Booth 2613 "Introducing Zetag® ULTRA Series of Cationic

Flocculants for High Shear Applications," by Emily Lindstrom,

Product and Applications Chemist, BASF

Exhibits:

3F Chimica

Americas/U.S. Polymers - Booth 2913

BASF - Booth 2613

Bomo (Beijing

Environmental Protection Technology) - Booth 4280

GE Water and

Power - Booth 4667, 4663

Kemira - Booth

4912

Xitao Polymer -

Booth 4467

2nd

Decision Tree Stop: Chemicals for Preliminary Dewatering 2nd

Decision Tree Stop: Chemicals for Preliminary Dewatering

The next

potential stop would be to look at chemical additions prior to the

BFP.

Speeches and Posters:

Monday

10:30 a.m. - Booth 2613 BASF Solutions for Global Water Challenges,

by Linda Muroski, Business Director, Water Solutions North America,

BASF

11:00 a.m. -

Booth 2613 "Introducing Zetag® ULTRA Series of Cationic Flocculants

for High Shear Applications," by Emily Lindstrom, Product and

Applications Chemist, BASF

Exhibits:

3F Chimica

Americas/U.S. Polymers - Booth 2913

BASF - Booth 2613

Bomo (Beijing

Environmental Protection Technology) - Booth 4280

GE Water - Booths

4667 and 4663

Kemira - Booth

4912

Xitao Polymer -

Booth 4467

3rd

Decision Tree Stop: Improve the Existing BFP Physical Performance 3rd

Decision Tree Stop: Improve the Existing BFP Physical Performance

The next most

fruitful trip will be the investigation of physical improvements to

the belt filter press operation. This could include new belts or

more extensive changes.

Speeches:

Wednesday - Room

S501A

8:30 a.m. -

Thickening and Dewatering, Moderator Jeanette Brown, Manhattan

College

9:30 a.m. -

Technical, Environment, and Economic Assessment of Sludge Thickening

Processes: A comparison of conventional and novel technologies

10:30 a.m. -

Seeking to Understand and Address the Impact of Biological

Phosphorous Removal on Biosolids Dewatering

11:30 a.m. - A

Systematic Approach to Understand and Optimize the Solids Dewatering

Process, Weihua Peng, United Water

This speech will

discuss applying a systematic approach of combining bench-scale and

full-scale testing techniques to assess the optimum operational

parameters for belt filter presses in order to maximize their

dewatering capability. It will also present, using advanced

statistical analysis, tools to rank the operational parameters in

terms of their effects on the performance of belt filter presses,

which allows utilities to allocate their limited resources to the

most influential process control parameters.

Exhibitors: Belt Presses

Andritz - Booth

2002

BDP

Infilco Degremont

- Booth 2431

Komline Sanderson

- Booth 3631

Phoenix Process

Equipment - Booth 504

Siemens

Exhibitors - Belts

GSM Filtration -

Booth 253

GKD - Booth 3250

4th

Decision Tree Stop Continuous Sludge Dryness Monitoring 4th

Decision Tree Stop Continuous Sludge Dryness Monitoring

Continuous

monitors are now available that may provide the needed dryness.

Speeches:

Monday: BASF

Stand 2613

3:30 p.m. -

Advances in Wastewater Treatment and Reuse (Bob McIlvaine, McIlvaine

Company)

Exhibitors:

Alfa Laval -

Booth 1031

Andritz

Separation - Booth 2002

Metso - Booth

1738

5th

Decision Tree Stop: Improve Automation of Sludge Dewatering Process 5th

Decision Tree Stop: Improve Automation of Sludge Dewatering Process

The response time

to changes in sludge characteristics is key to obtaining a drier

sludge. Automation of the process using the sludge dryness monitor

as one of the inputs is beneficial.

Speeches:

Monday: BASF -

Stand 2613

3:30 p.m. -

Advances in Wastewater Treatment and Reuse (Bob McIlvaine, McIlvaine

Company)

Exhibitors:

Emerson - Booth

4067

Invensys - Booth

3678

Rockwell

Automation - Booth 3243

Siemens - Booth

1431

YSI (Xylem) -

Booth 1443

6th

Decision Tree Stop: Install New Gravity Sludge Conditioning Device 6th

Decision Tree Stop: Install New Gravity Sludge Conditioning Device

Speeches:

Wednesday Room

S501A

8:30 a.m. -

Optimizing Gravity Thickeners Performance at The World's Largest

Advanced WWTP by David Parker, HDR Engineering

9:00 a.m. -

Thickening Primary Solids for Digester Operational Enhancement at

the Hyperion Treatment Plant, City of Los Angeles by Edick Ohanian,

City of Los Angeles

Exhibitors: Gravity Belt Thickeners

Andritz - Booth

2002

Komline Sanderson

Exhibitors: Belts

GSM Filtration -

Booth 253

GKD - Booth 3250

7th

Decision Tree Stop: Install New Dewatering Device 7th

Decision Tree Stop: Install New Dewatering Device

Speeches:

Wednesday - Room

S501A

9:30 a.m. -

Technical, Environmental, and Economic Assessment of Sludge

Thickening Processes: A comparison of conventional and novel

technologies:

Exhibits-Centrifuges

Alfa Laval -

Booth 1031

Andritz - Booth

2002

Centrisys- Booth

2619

Flottweg - Booth

2236

GEA Westfalia -

Booth 617

Noxon - Booth

3288

Shanghai

Centrifuge - Booth 2675

Filter Press - Recessed Chamber

Lenzing - Booth

1874

Sludge Dryness

Route Map in GDPS will be Updated, Expanded and Sent to you again

Next Week.

Next Thursday we

will send you an updated and expanded dryness route map. If you have

a contribution to make to sludge dryness and will be exhibiting or

walking the floor at WEFTEC then we want to include you. If you are

not an exhibitor, we will need your cell phone so that people can

contact you during the show. If you are an exhibitor, we can just

use the booth name. However if you have a specialist on dryness,

then it would be good to provide his name and mobile number to us.

Sludge Dryness

GDPS Route Map will be Permanent

This route map

will be continually expanded to cover the full range of activities

relative to obtaining drier sludge. It will be one of many routes in

the municipal wastewater secondary treatment GDPS. This system will

be available free of charge to any municipal wastewater plant

employee in any country. There will be a subscription fee for

others. Contact McIlvaine for the details.

Some WEFTEC Highlights

BASF Unveils New

Polymer And Schedules Five Speeches At Stand 2613

At Booth 2613,

BASF will unveil Zetag® ULTRA, a new cationic flocculant

range offering high performance even in the toughest applications.

BASF will also feature its new T-Rack® 3.0 based on inge®

ultrafiltration membrane technology for seawater desalination and

wastewater reuse. In addition, attendees are invited to the booth

for 15-minute presentations from BASF and Bob McIlvaine, President

of the McIlvaine Company (schedule below).

"BASF is

committed to providing sustainable solutions to address the world's

rising water demands," said Linda Muroski, Business Director for

BASF Water Solutions in North America. "Our extensive product

portfolio of water treatment products, investment in R&D and

collective strength of our growing team is helping our customers

meet their water management goals."

The new products

BASF will introduce at WEFTEC align with customer needs for improved

water treatment solutions, such as high performance flocculants and

membrane technologies. The Zetag® ULTRA flocculant range

offers strong floc integrity for high shear applications and can be

used in highly variable sludge conditions. It is especially

effective for plants that use centrifuge, flotation and gravity belt

thickener processes. It offers a significant dosing reduction

compared to the market standard. As a result of its effectiveness,

operational cost savings and a reduction in biosolids transport and

landfill disposal costs can be achieved.

The T-Rack 3.0 is

a compact ultrafiltration solution to address the specific

requirements of larger-scale filtration systems such as those used

for the pretreatment in seawater desalination or wastewater reuse.

It meets the key requirements of corrosion resistance and high

pressure operability at high temperatures and also supports greater

treatment capacity. In addition, the T-Rack's plug and play

installation lowers the amount of maintenance required.

BASF Presentation

Schedule at WEFTEC

Monday, October 7

10:30 a.m. -

Keynote Address - BASF Solutions for Global Water Challenges, by

Linda Muroski, Business Director, Water Solutions North America,

BASF

11:00 a.m. -

"Introducing Zetag® ULTRA Series of Cationic Flocculants

for High Shear Applications," by Emily Lindstrom, Product and

Applications Chemist, BASF

2 p.m. - "Inge®

Ultrafiltration Membrane and Modular Technology," by Tim Letourneau,

Head of Membrane Solutions, BASF

3:30 p.m. -

"Trends in Municipal Waste Water Treatment and Reuse" by Bob

McIlvaine, President, McIlvaine Company

Tuesday, October

8

10 a.m. - "How

Can Chemistry Be a Strong Enabler for the Chemical Industry?" by

Yannick Fovet, Head of Global Development for Water Solutions and

Membrane Technology

Andritz - Booth

#002

Centrysis - Booth

2619

Centrisys

engineers created the THK from the ground up to require no polymer -

even while increasing flow rates. The company states that a facility

can save up to $140,000 annually p/dry ton for WAS - and earn full

ROI in 2.5 years based on those savings alone.

Crane - Booth

4626

Danfoss (Booth

1241) - InterWEBviewT with McIlvaine is good preparation before you

visit their booth.

InterWEBview with Jeffrey Bergman of

Danfoss

Danfoss provides VLT®

variable frequency drives to control speed, torque, acceleration,

synchronization, positioning, and the overall performance of AC

motors. The reliable and innovative VLT® drives are

designed to support any automation application and provide major

energy savings.

InterWEBview:

Danfoss drives for wastewater

treatment plants- InterWEBviewT with Jeffrey Bergman

YouTube:

Danfoss drives for wastewater

treatment plants- InterWEBviewT with Jeffrey Bergman

Ebara Fluid

Handling - Booth 2915

Gardner Denver -

Booth 1412

GE Power & Water

- Booth 4667, 4663

GE's RootsT

Blowers, Compressors and Controls - High Performance and Energy

Savings

GE Oil & Gas

offers Roots blowers, compressors and controls, innovative, advanced

air and gas handling products ranging in size and features from

small and large rotary lobe blowers and standard blower and

compressor packages to custom blower and compressor packages and

centrifugal compressors and controls systems.

Roots blowers and

compressors technology is built on a heritage of engineering and

manufacturing expertise dating back to the Roots brothers' discovery

of the principle of the rotary positive displacement blower in 1854.

Today, Roots

aeration controls systems technology delivers customers savings of

up to 40 percent of the energy used for WWT aeration.

GEA - Booth 617

Satin Weaves are the most commonly chosen fabric

style for municipal sludge dewatering. Satin weaves offer high

solids capture rates, good cake release, and fabric strength.

Spiral link fabrics offer superior fabric life and

have the added benefit of no clipper seams. Spiral belts when

assembled are essentially endless. Many municipal wastewater plants

are now using spirals for the top and bottom press zones and are

particularly useful for older machines.

Plain weave

fabrics

are mostly used

for very high drainage rates and are typically found on gravity

tables in applications with very high coarse material sludge.

IDEX - Booth 1605

Kemira - Booth

4912

LSC Environmental

- Booth 1412

PALL - Booth 1372

Pentair - Booth

2023

Purafil - Booth

3003

Noxon North

America - Booth 3288

Siemens Process

Instrumentation and Analytics - Booth 5163

Siemens Water

Technologies - Booth 1431

Singer Valve -

Booth 1969

Wilo USA - Booth

#076

Xylem - Booth

1443, 3940

Additional

Highlights will be Added Next Week

If you are a

McIlvaine client and would like to see a highlight on your stand at

WEFTEC, please communicate with us in the next few days.

----------

Municipal Wastewater Insights

is available free of charge along with a number of other

publications. You can register to receive them at: http://www.mcilvainecompany.com/brochures/Free_Newsletter_Registration_Form.htm.

Bob McIlvaine

President

847 784 0012 ext 112

rmcilvaine@mcilvainecompany.com

www.mcilvaine@mcilvainecompany.com

191 Waukegan Road Suite 208 | Northfield | IL 60093

Ph: 847-784-0012 | Fax; 847-784-0061

|