A Descriptive Definition of Valve Actuators

By Chris Warnett, Rotork Controls Inc

A valve actuator is any device that utilizes a

source of power to operate a valve. This source of power can be a human being

working a manual gearbox to open or close a valve, or it can be a smart

electronic device with sophisticated control and measuring devices. With the

advent of micro-circuitry the trend has been for actuators to become more

sophisticated. Early valve actuators were no more than a geared motor with

position sensing switches. Today’s valve actuators have much more advanced

capabilities. They not only act as devices for opening and closing valves, but

can also check on the health and well being of a valve as well as provide

predictive maintenance data.

What is an actuator?

An actuator in its broadest definition is a device that produces linear or

rotary motion from a source of power under the action of a source of control.

Actuators take fluid, electric or some other source of power and convert it

through a motor, piston or other device to perform work. Basic actuators are

used to move valves to either fully opened or fully closed positions. Actuators

for control or position regulating valves are given a positioning signal to move

to any intermediate position with a high degree of accuracy. Although the most

common and important use of an actuator is to open and close valves, current

actuator designs go far beyond the basic open and close function. The valve

actuator can be packaged together with position sensing equipment, torque

sensing, motor protection, logic control, digital communication capacity and

even PID control all in a compact environmentally protected enclosure.

Figure 1: Basic electric actuator components

As automation is adopted in more facilities, physical work is being replaced

by machines and their automatic controls. The need for valve actuators to

provide the interface between the control intelligence and the physical movement

of a valve has grown. There is an important need for the increased working

safety and the environmental protection that valve actuators can provide. Some

areas are hazardous or hostile to human beings. In these circumstances an

automated actuation device can reduce the risk to the individuals. Certain

critical valves need to be opened or closed rapidly in the event of emergency

circumstances. The valve actuator can prevent serious environmental catastrophes

as well as minimize damage to facilities in such circumstances. With some

processes requiring high pressures and large line sizes, the amount of power

required to open or close a valve can be significant. In these circumstances the

enhanced mechanical advantage and application of high output motors can

facilitate easy operation of large valves.

Valves and automation

In order to successfully automate a process it is essential to make sure that

the valve itself is appropriate to handle the special demands of the process and

the product in the pipeline. It is the process or product that should dictate

the type of the valve, the closure element of the valve, trim requirements and

material of construction.

Once a valve has been selected the next step is to consider the application’s

automation requirements. These can be simplified by examining the two basic

types of valve operation from an actuator’s perspective.

- Rotary or quarter-turn operation. This group would include plug valves,

ball valves, butterfly valves as well as quarter-turn dampers. A simple 90° of

movement at the prescribed torque demand is required.

- The other group of valves can be classified as multi-turn. These are

valves that have rising non-rotating stems or non-rising rotating stems. In

other words they require multiple turns to move the valve closure element from

open to close. This group would include globe valves, gate valves, knife

gates, sluice gates, etc. Alternatively, linear, pneumatic or hydraulic piston

operators or diaphragm pneumatic actuators could be used.

Figure 2: Multi turn & quarter turn actuators

There are four fundamental types of actuators. These are a combination of the

type of power applied and the type of movement required at the valve.

- Electric multi-turn actuators –The electrically powered multi-turn

actuators are one of the most common and dependable configurations of

actuators. A single or three-phased electric motor drives a combination of

spurs and/or level gears, which in turn drive a stem nut. The stem nut engages

the stem of the valve to open or close it, frequently via an Acme threaded

shaft. Electric multi-turn actuators are capable of quickly operating very

large valves. To protect the valve, the limit switch turns off the motor at

the ends of travel. The torque sensing mechanism of the actuator switches off

the electric motor when a safe torque level is exceeded. Position indicating

switches are utilized to indicate the open and closed position of the valve.

Typically a declutching mechanism and hand wheel are included so that the

valve can be operated manually should a power failure occur. The main

advantage of this type of actuator is that all of the accessories are

incorporated in the package and are physically and environmentally protected.

It has all the basic and advance functions incorporated in a compact housing

which can be water tight, explosion proof and in some circumstances,

submersible. The primary disadvantage of an electric multi-turn actuator is

that, should a power failure occur, the valve remains in the last position and

the fail-safe position cannot be obtained easily unless there is a convenient

source of stored electrical energy.

- Electric quarter-turn actuators –These units are very similar to an

electric multi-turn actuator. The main difference is that the final drive

element is usually in one quadrant that puts out a 90° motion. The newer

generation of quarter-turn actuators incorporates many of the features found

in most sophisticated multi-turn actuators. For example, a non-intrusive,

infrared, human machine interface for set up, diagnostics, etc. Quarter-turn

electric actuators are compact and can be used on smaller valves. They are

typically rated to around 1,500 foot pounds. An added advantage of a smaller

quarter-turn actuators is that, because of their lower power requirements,

they can be fitted with an emergency power source such as a battery to provide

failsafe operation.

- Fluid power quarter-turn actuators –Pneumatic and hydraulic quarter-turn

actuators are extremely versatile. They can be used where there is no readily

available electric power or where simplicity and reliability are essential.

They can also withstand considerable mechanical abuse. Their range of

applications is enormous. For example, the smallest can deliver a few inch

pounds of torque where the largest are capable of producing in excess of a

million inch pounds of torque. Almost all fluid power actuators utilize a

cylinder and a mechanism to covert the linear motion generated in the cylinder

to a quarter-turn motion. The main types of mechanism are scotch yoke, lever

and link and the rack and pinion. The rack and pinion type gives constant

torque output throughout the stroke so, they are useful for smaller valves.

The scotch yoke is effective for larger valves where a higher torque

requirement is needed at the beginning of the stroke. Pneumatic actuators are

usually controlled by solenoid control valves that are mounted on the

actuator, sometimes in combination with position indicating switches. A

positive failure mode can easily be affected with a pneumatic or fluid power

actuator by the addition of an opposing spring to provide a positive shut down

in an emergency.

Figure 3: Gas driven actuator

Figure 4: Hydraulic spring return fluid power actuator

- Fluid Power multi-turn actuators –These types of actuators are frequently

used when multi-turn output is required to operate a linear type valve such as

a gate or globe valve. Frequently electric actuators are used for this type of

valve. However, if there is no electric power supply readily available, then

pneumatic or hydraulic motors can be used to operate multi-turn actuators.

Selection criteria

:When selecting a valve actuator the correct type and size can be found

utilizing the following selection criteria:

- Power source –The common sources of power for automated valves are

electricity or fluid power. If electric power is selected, a three-phase

supply is usually required for large valves; however, small valves can be

operated on a single-phase supply. Usually an electric valve actuator can

accommodate any of the common voltages. Sometimes a DC supply is available.

This is often an emergency back-up power supply.

Variations of fluid power are much greater. First there is a variety of fluid

media such as compressed air, nitrogen, hydraulic fluid or natural gas. Then,

there are the variations in the available pressures of those media. With a

variety of cylinder sizes, most of the variations can be accommodated for a

particular valve size.

- The type of valve –Whenever sizing an actuator for a valve, the type of

valve has to be known, so that the correct type of actuator can be selected.

There are some valves that need multi-turn input, where as others need

quarter-turn. This has a great impact on the type of actuator that is

required. When combined with the available power supply, then the size and

type of actuator quickly comes into focus.

Generally multi-turn fluid power actuators are more expensive than multi-turn

electric actuators. However, for rising non-rotating stem valves a linear

fluid power actuator may be less expensive. A definitive selection cannot be

made until the power requirements of the valve are determined. After that

decision has been made, then the torque requirement of the valve is the next

selection criterion.

- Calculating the torque required by the valve –For a quarter-turn valve,

the best way of determining the torque required is by obtaining the valve

maker’s torque data. Most valve makers have measured the torque required to

operate their valves over the range of operating line pressures. They make

this information available for customers.

The situation is different for multi-turn valves. These can be subdivided into

several groups: the rising rotating, rising non-rotating, and non-rising

rotating valves. In each of these cases the measurement of the stem diameter

together with the lead and pitch of the valve stem thread is required in order

to size the automation for the valve. This information coupled with the size

of the valve and the differential pressure across the valve can be used to

calculate torque demand.

The type and size of the actuator can be determined after the power supply,

the type of valve, and the torque demand of that valve have been defined.

- Sizing the actuator –Once the actuator type has been selected and the

torque requirement of the valve has been determined, then the actuator can be

sized using one of the actuator manufacturer’s sizing programs or tables. A

further consideration in sizing the actuator is the required speed of

operation of the valve. As speed has a direct relationship to the power

required from the actuator, more horsepower would be needed to operate a valve

at a faster speed.

Fluid power actuators can adjust speed of operation using fluid control

valves. However, electric motor operators of the three-phase type have a fixed

speed of operation. Smaller, quarter-turn actuators utilize DC motors, and may

have adjustable speed of operation.

Controls

The great advantage of having an automated valve is that it can be remotely

controlled. This means that operators can sit in a control room and control a

process without having to physically go to the valve and give it an open or

close command, the most basic type of control for an automated valve. The

ability to remotely control a valve is easily achieved by running a pair of

wires out to the actuator from the control room. Applying power across the wires

can energize a coil, initiating motion in an electric or fluid power actuator.

Positioning a valve in an intermediate position can be done using this type of

control. However, feedback would be needed to verify the actuator is at the

desired position. A more common method of positioning an actuator is to feed a

proportional signal to the actuator such as 4-20 mA, so that the actuator, using

a comparator device, can position itself in direct portion to the received

signal.

Modulating control

If an actuator is required to control a level, flow or pressure in a system,

then it may be required to move frequently. Modulating or positioning control

can be achieved using the same 4-20 milliamps signal. However, the signal would

change as frequently as the process required. If very high rates of modulation

are required then special modulating control valve actuators are needed that can

accommodate the frequent starts required for such duty.

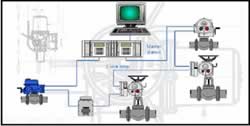

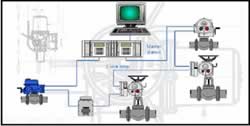

Figure 5: Digital communication systems

Where there are many actuators on a process, the capital cost of installation

can be reduced by utilizing digital communication over a communicating loop that

passes from one actuator to another. A digital communication loop can deliver

commands and collect actuator status rapidly and cost effectively. There are

many types of digital communication such as Foundation Fieldbus, Profibus,

DeviceNet, Hart, as well as proprietary communication systems custom designed

for valve actuator use such as Pakscan. Digital communication systems have many

advantages over and above the saving in capital cost. They are able to collect a

lot of data about the condition of the valve, and as such can be used for

predictive maintenance programs.

Predictive maintenance

Motor operators can utilize built-in data loggers coupled with highly accurate

torque sensing mechanisms to record data on the valve as it moves through its

stroke. The torque profiles can be used to monitor changes in the operating

conditions of the valve and to predict when maintenance is required. They can

also be used to trouble shoot valves.

Forces on a valve can include the following:

- Valve seal or packing friction

- Valve shaft, bearing friction

- Valve closure element seat friction

- Closure element in travel friction

- Hydro-dynamic forces on closure elements

- Stem piston effect

- Valve stem thread friction

Most of these are present in all types of valves, but in varying degrees of

magnitude. For example, closure element travel friction in a butterfly valve is

negligible. Where as a non-lubricated plug valve has significant in travel

friction. Valve actuators are designed to limit their torque to a preset level

using a torque switch, usually in a closing direction. An increase in torque

above this level will stop the actuator. In the opening direction, the torque

switch is frequently bypassed for the initial unseating operation. The resulting

torque profile is useful in analyzing the valve condition.

Figure 6: Gate valve torque profile

Different types of valves have different profiles. For example, a wedge gate

valve has significant torque at the opening and closing positions. During the

remaining portion of the stroke the torque demand is made up of packing and

thread friction on the acme threaded shaft. On seating, the hydrostatic force on

the closure element increases the seating friction, and finally the wedging

effect of the closure element in the seat causes a rapid increase in torque

demand until seating is completed. Changes in torque profile can therefore give

a good indication of pending problems and can provide valuable information for

an effective predictive valve maintenance program.

This article was originally published in the June 2004 issue of Valve World

magazine.