Coronavirus Technology Solutions

June 10, 2020

Overview

June 10 Face Mask News

Membrane Mask with Silver Being Developed by UK

TTG has Membrane Media for Face Masks with a

Number of Claimed Advantages

Transparent Mask Developed by Swiss

Mask Policy Review

Should We Rethink our Whole Mask Policy?

Should task # 1 be to protect individuals rather

than keep them from being spreaders?

Virus Factors

Mask Factors

Wearer factors

Environment

Facemask Performance Articles in Previous Alerts

Silicon Based Membrane for Masks has Efficiency

and Other Advantages

Fibre Extrusion Technology Says There May Be

Better Answers Than Polypropylene for Meltblowns

NXTNano has Nanofiber Media Available for Face

Masks

Tustar Teams with Neatrition to Introduce High

Efficiency Masks to the U.S. Market

Sciessent

Antimicrobial Used in Hanesbrands Masks

Teho Filter Using Ahlstrom Media for N88 Masks

in Finland

Russian Scientists Develop Nanofibers for Masks

O2 Nano Mask is Low Pressure Drop, Efficient and

Reusable

Cambridge has an Efficient and Comfortable Mask

but with Valve

Masks are Part of a Combined Program to Reduce

the Odds to Near Zero

Airplanes are Relatively Safe with the Following

Guidelines

Midwest Textiles, Hollingsworth & Vose Partner

to Develop Homemade Facemask Kit

Bondex Ramps up Production of Material for PPE &

N95 Facemasks

Ultra-Pure PM 0.1 Mask Filter from Asiatic Fiber

Corporation

Ahlstrom -Munksio Media Being Used by French

Mask Makers

Ava Breathe has Unique Mask Design

High Fashion Mask is Available from Lumen

Couture

Website Dedicated to Analyzing Mask

Decontamination Options

N95 Masks Much Safer than Medical Masks for

Wearers

Avantor in Unique Position To Supply Products to

Mitigate the Coronavirus

Upscale KN95 Masks Available

Do we Need Masks with Valves for Certain People

and Certain Situations?

Chinese N95 Masks Shipped to Massachusetts did

not Meet Requirements

Alpha Pro Tech Expands Production of Face Masks

Masks with Valves have Advantages but Design and

Maintenance are a Challenge

ExxonMobil has New Filtration Fabric and Mask

Design

Spectrashield Meets Efficiency Requirements

Berry Global has New Material for Surgical Masks

NC State Develops Two Polymer Spunbond for Masks

Which Can Be Sewn and is Washable

Hospital Using MSA Respirators With Replaceable

Cartridge

MSA Has a Range of Respirator Designs Available

to Protect Hospital Personnel

Sindat Now Producing Efficient Masks with

Replaceable Membrane

Cummins and Dupont are Working Together to Help

Address the Current Shortage of N95 Masks

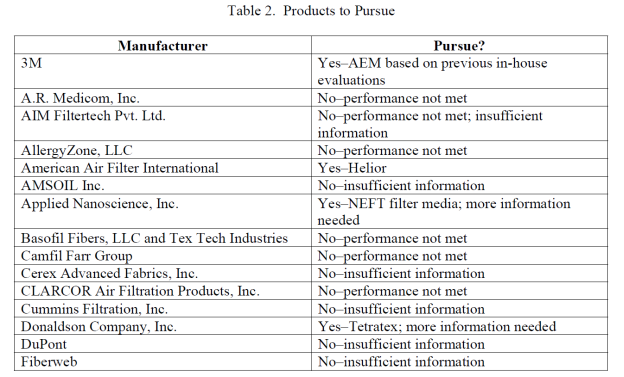

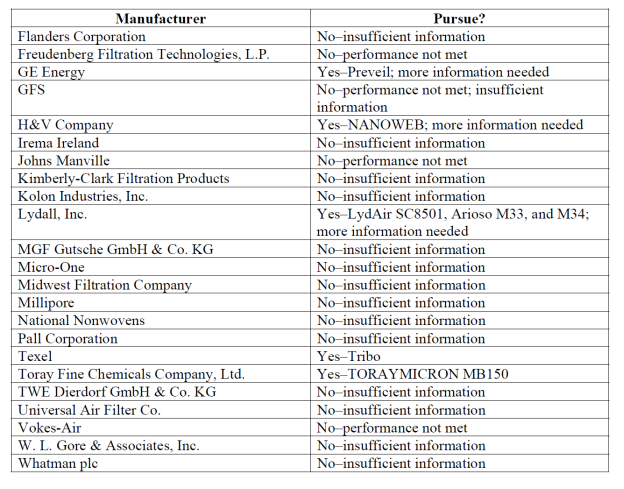

U.S Army Research on Face Mask Media will be

Helpful

Fibertex Non Wovens has New HEPA Filter Media

for Filters and Respirators

Alternative coverstock media from

Ahlstrom-Munskjo

Social Distancing Alternative with Low Risk and

Modest Cost for Coronavirus Mitigation

The Mask Market Could Soar From a Few Billion

Per Year to Hundreds of Billions

Superior Felt and Filtration has Both Meltblown

and Needle Punched Media for Masks

SWM supplies Melt Blown Media and Film for

Surface Layer

____________________________________________________________________________

Overview

Efficient masks remove virus aerosols and

protect wearers. Inefficient or loose fitting

masks may capture less than 20 percent of the

aerosols. New evidence reveals that virus

aerosols are a significant transmission route.

The guidelines and advice given to the public

are to wear masks not for self- protection but

to protect others. McIlvaine Company questions

this policy and is trying to understand all the

many factors which should impact mask

decisions. In this pursuit a webinar open to

everyone will be held on June 18 at 10:00AM

CDT. The proposition to be discussed and debated

is Should the primary use of masks be to

protect the wearer?

A number of recent research papers validate

airborne transmission of small virus aerosols

along with the possibility that even long

distance travelers may become dormant but are

revitalized when they are inhaled. Efficient N95

masks will capture these aerosols. However, this

type of mask is uncomfortable unless it is

equipped with a valve to allow unfiltered breath

to be exhaled. For this reason masks with valves

are prohibited in some communities and not

recommended in general guidelines.

Masks have proven to be extremely effective in

protecting asbestos workers, Asian citizens in

high air pollution areas and those with immune

deficiencies. The moon has a hostile atmosphere

but man has walked its surface. The common

denominator is that the danger of the conditions

is accepted and masks are designed to keep the

wearer safe. The webinar will probe ways that

more efficient N80 masks without valves can be

made available to billions of people. It will

cover the potential for a range of masks

including some with valves to be used depending

on individuals and circumstances.

This Alert has been expanded to include the

previous articles relevant to mask performance

and the various designs available and under

development. Important material selection

information is highlighted in red

Attendees are invited to submit data in advance

and participate in the general discussion during

the webinar. For more information and to

register Click

here

June 10 Face

Mask News

Membrane Mask with Silver Being Developed by UK

As the world continues to respond to the

COVID-19 pandemic, the University of Kentucky

continues its work to confront the virus through

innovative research and collaboration.

With funding and support

from Kentucky's National Science Foundation

(NSF)-sponsored Established Program to Stimulate

Competitive Research (EPSCoR),

a team from UK and Somerset Community College

(SCC) is creating 3D-printed, membrane-filtered

face masks that can inactivate the coronavirus.

The goal, through passive decontamination, is to

not only protect people from breathing in

viruses, but to eliminate them on contact.

Isabel Escobar, professor of chemical and

materials engineering in the UK College of

Engineering and associate director of UK’s

Center of Membrane Sciences, is working to

perfect the central component of the masks — the

filter. This filter will contain a unique

membrane composed of a polymer dissolved in a

nontoxic, bio-derived solvent, which will then

be chemically bound to medical-grade silver

nanoparticles, known for their antiviral

efficiency.

“The virus is about 120 nanometers in size — in

the world of membranes, that's large,” Escobar

said. “Even more so, it's not going to come as a

virus by itself, flying in the air. It's going

to come in the saliva, so it's going to be a

much larger particle. A large particle is just

not going through (this filter).”

But Escobar’s research takes it a step further,

adding the silver nanoparticles for the passive

disinfection.

“(The silver nanoparticles) prevent the virus

from binding and attaching, and it inactivates,”

she said.

Eric Wooldridge, professor of additive

manufacturing at SCC, and his team will be

providing the substrates, or the structure, of

the masks. These substrates, made of

polypropylene, will be 3D-printed in a honeycomb

pattern to allow for a strong, breathable

structure. The antiseptic membranes from

Escobar’s team will then line the insides,

ultimately creating a safer, cost-effective and

environmentally sustainable PPE that would match

or exceed N95 mask requirements.

“Utilizing SCC’s additive manufacturing

capabilities to produce the base components

combined with UK’s groundbreaking nanotechnology

to provide the coatings, our goal is to not only

demonstrate that it can be done, but that we can

rapidly scale production through our KCTCS

additive manufacturing network,” Wooldridge

said. “This collaboration represents one of the

primary goals of the KY NSF EPSCoR program:

bridging the gap between theoretical research

and practical application to rapidly respond to

a need and create solutions that truly matter to

the Commonwealth.”

“I love the fact that the 3D-printed supports

are from a collaboration with a community

college,” Esocbar said. “This shows that without

the help of a community college, this project

would not have been possible. We are, all

together, an intellectual force.”

Escobar, originally from Rio de Janiero, Brazil,

has spent the majority of her life working on

membrane filtration, with the focus of providing

clean water access to the world. When the

COVID-19 pandemic hit, Escobar realized her work

could also be applied to filtering viruses.

The team's antiviral masks have the potential to

positively impact the state, nation and world in

response to COVID-19. The collaboration is an

example of how KY NSF EPSCoR’s supported

researchers have the knowledge base and

creativity to pivot their research in the midst

of a public health crisis.

“KY NSF EPSCoR is in a unique position to see

connections between projects that are unknown to

researchers — without their vision, my idea of

making passive disinfection face masks using

membranes might have stayed as just an idea,”

Escobar said. “But thanks to the vision of KY

NSF EPSCoR, Eric Wooldridge and I connected and

were able to not only develop a short-term plan

to make face masks but also develop a long-term

plan for research at the forefront of

innovation.”

The KY NSF EPSCoR funding comes a month after a

similar project at UK was funded by an NSF Rapid

Response Research (RAPID) grant. This

project,

led by UK’s Dibakar Bhattacharyya (known to

friends and colleagues as “DB”), also seeks to

develop antiviral membrane masks, but through

different means. DB, who is director of the UK

Center of Membrane Sciences, is a mentor and

colleague of Escobar, and actually recruited and

brought her to UK in 2015.

“I have to say (DB) is probably one of the

people that I respect the most in the world,

probably one of the most brilliant minds alive,

and he and I spend a lot of time discussing

research ideas,” Escobar said. “We have a lot of

projects at the Center of Membrane Sciences. We

aim to determine how membrane science and

technology can help solve problems communities

are facing.”

http://uknow.uky.edu/research/uk-scc-team-confront-covid-19-antiviral-membrane-3d-printed-face-masks

TTG has Membrane Media for Face Masks with a

Number of Claimed Advantages

Trinity Technology Group’s (TTG) created a new

AIRADIGM three-layer composite medical face mask

media.

“We are proud that our proprietary AIRADIGM

technology can help better protect people on the

front lines of healthcare today,” said Greg Vas

Nunes, TTG’s CEO. “We applied our significant

experience in membrane and fabric construction

to create a composite material that provides

several unique performance features not

currently available.”

AIRADIGM composite face mask material is a

proprietary design that features:

·

Spun-lace polyester outside layer for

durability;

·

ePTFE membrane core for enhanced filtration and

breathability;

·

Spun-bond polypropylene inside for softness and

moisture management; and

·

The composite media is sonically laminated for

integrity and increased mask lifespan.

·

This unique, lightweight, bonded composite keeps

fluids and particles out but allows body heat

and vapor to escape for long term comfort. Also,

the composite’s membrane core is breathable and

increases the wearer’s protection. Studies have

shown that PPE comfort is a must for user

compliance and concentration, both of which are

absolutely critical in medical settings.

·

The proprietary membrane provides filtration

capabilities that do not degrade with humidity

unlike traditional melt blown mask materials.

Microbe and particle protection levels stay

consistently high for all-day protection without

frequent mask replacement. Masks made with the

special AIRADIGM media can be autoclaved and

safely reused. These benefits relieve the stress

on the PPE supply chain and improve return on

investment. Plus, substantially fewer masks end

up in landfills.

·

Third party testing and certification is under

way at Nelson Labs to confirm that the AIRADIGM

surgical grade face mask media exceeds ASTM

F2101 for Bacterial and Viral Penetration, ASTM

F1862 for Blood Penetration, and ASTM F2299 for

Particulate Infiltration, key criteria for N95

and ASTM Level 3 face masks.

Transparent Mask Developed by Swiss

A fully transparent surgical mask that filters

out germs but allows facial expressions to be

seen has been developed by Swiss scientists.

Caregivers should be able to wear them from the

summer of 2021.

For some segments of the population – like

children, the elderly and the hearing impaired –

the [current] masks are a major obstacle to

communication,” said the Swiss Federal

Laboratories for Materials Science and

Technology (EMPA) in a statement on Tuesday.

Along with researchers at the Swiss Federal

Institute of Technology Lausanne (EPFL), EMPA

has been working for two years on a completely

transparent surgical mask.

They have now finalized a biomass-based material

to manufacture the so-called HelloMasks and have

created a start-up called HMCARE, based on the

Biotech campus in Geneva, to market them.

The EMPA and EPFL researchers spent two years

finding the right combination of transparency,

resistance and porosity. They eventually came up

with a membrane made from a polymer developed

specifically for this application.

Because the new masks will be disposable for

optimal efficacy, like existing surgical masks,

the researchers focused from the start on

finding a material that was either recyclable or

biodegradable. “Our masks are made at 99% from a

biomass derivative, and we’ll keep working on

them until they’re completely eco-friendly,”

Pelet says.

Mask Policy Review

Should We Rethink our Whole Mask Policy?

Mask policy to combat COVID is based not on

protecting the wearer but on protecting others

from being infected by the wearer. There is an

argument to be made that the emphasis should be

the other way around.

If everyone is protected then stopping

the virus at its source is not so critical. It

is appealing to just focus on stopping the

source as you would by just turning off a garden

hose.

But if the water is already part of

a rain storm, source control is too

challenging. Virus in big cough droplets can be

likened to the garden hose whereas virus

aerosols can be likened to the rain storm.

We have mounting evidence that at least some

of the COVID transmission is through small

droplet aerosols or on virus attached to small

particles. The argument can be made that the

most important safeguard will be a highly

efficient N95 or even N99 mask. Here are some

examples

·

Medical personnel

are exposed to thousands of times more

COVID than others but they wear N95 or even more

efficient masks and avoid infection

·

60 choir members in Washington State attended a

2 hour choir practice but sanitized everything

and kept 6 feet apart. 45 of them became

infected.

If they had worn surgical masks maybe

only 25 would have become infected. If they had

all worn N95 masks none of them should have

become infected.

·

At a Southern China restaurant where the air

conditioner spread COVID N95 masks could have

prevented the spread.

·

If those passengers on the Diamond Princess

isolated in their cabins and inhaling viruses

through the HVAC system had instead roamed the

ship in N95 masks they would have been spared.

Should task # 1 be to protect individuals rather

than keep them from being spreaders?

What hospital would want to put efficient masks

on COVID patients but leave medical personnel

without protection?

In theory the concept works well. Just

control a few patients and then not have to

worry about anyone else. In practice the obvious

result would be disaster as COVID leaks would

soon fell the medical

workers. The takeaway is that it is very

difficult to prevent COVID from entering the

air.

The same could be said for the concept

that wearing inefficient masks will efficiently

capture any virus generated by the wearer Since

these masks are rated at very low efficiency on

0.3 micron particles and since they do not fit

tightly most aerosols will pass through or

around the mask

There are many arguments

to be made for and against this new

concept. They all depend on facts which are in

dispute or not clearly understood.

McIlvaine will be conducting a webinar on

June 18 to discuss all of the following

factors.

Virus Factors

·

The size and proliferation of aerosols

·

The percentage of virus in aerosols versus

larger droplets

·

The viral load

·

Minimum infectious dose

·

Life of virus

·

Virus rejuvenation from dormancy

·

Creation of aerosols from viruses leaving

surfaces

·

Efficiency of various masks in removing viruses

·

Various mask media options

·

Wash ability

·

Efficiency reduction over time or with washing

·

Mask fit

·

Comfort

·

Breathability and oxygen deprivation

·

Valve options

·

Killing as well as capturing viruses

·

Age and immune response

·

Other

medical conditions

·

Lung function

·

Activities

Environment

·

Virus load

·

Percentage of aerosols

·

Humidity

·

Air flow patterns

·

Benefits of capturing other contaminants

Virus Factors

Size and proliferation of Aerosols.

We breathe in millions of particles per minute

but must avoid just 10 viral particles.

Small particles such as virus aerosols are

invisible. This can provide a false sense of

safety. In every cubic meter of air we inhale we

also inhale 35 million particles greater than or

equal to 0.5 microns in diameter.

We inhale even more

smaller particles in the 0.1 to 0.2

micron range

which is the size of the virus.

The following table is designed to rate

cleanrooms.

ISO 14644-1 Cleanroom Standards

|

Class |

maximum

particles/m3 |

FED STD 209E |

|||||

|

>=0.1 µm |

>=0.2 µm |

>=0.3 µm |

>=0.5 µm |

>=1 µm |

>=5 µm |

||

|

ISO 1 |

10 |

2 |

|

|

|

|

|

|

ISO 2 |

100 |

24 |

10 |

4 |

|

|

|

|

ISO 3 |

1,000 |

237 |

102 |

35 |

8 |

|

Class 1 |

|

ISO 4 |

10,000 |

2,370 |

1,020 |

352 |

83 |

|

Class 10 |

|

ISO 5 |

100,000 |

23,700 |

10,200 |

3,520 |

832 |

29 |

Class 100 |

|

ISO 6 |

1,000,000 |

237,000 |

102,000 |

35,200 |

8,320 |

293 |

Class 1,000 |

|

ISO 7 |

|

|

|

352,000 |

83,200 |

2,930 |

Class 10,000 |

|

ISO 8 |

|

|

|

3,520,000 |

832,000 |

29,300 |

Class 100,000 |

|

ISO 9 |

|

|

|

35,200,000 |

8,320,000 |

293,000 |

Room Air |

There are some reports that the minimum

infectious dose for COVID -19 can be as low as

10 viral particles.

This means that if just a tiny fraction

of the particles we inhale every minute are

COVID we can become infected. For comparison

purposes a pharmaceutical cleanroom typically is

ISO 5.

The cleanest operating theaters in

hospitals are ISO 4. The semiconductor industry

spends billions of dollars per year to reach ISO

3. The task of keeping small particles such as

viruses from occupying space is very difficult.

Many of the particles we inhale are long

distance travelers. For example mercury emitted

from gold mines in Brazil has been traced to the

Artic. When a volcano erupted in Iceland the

skies turned dark in Europe for weeks. Italian

researchers have found COVOD on air pollution

particles in the Lombardy region. Another

takeaway is that social distancing has limited

effectiveness.

Viruses travel on cigarette smoke sized

particles.

So one way to view the task is to think

that everyone you encounter is puffing away and

you have to avoid even inhaling a few of his

smoke particles.

The percentage of virus in aerosols versus

larger droplets:

Viruses attach to droplets or particles.

They are only 0.1 microns in diameter but may be

in droplets 20 microns in diameter or larger.

Droplets in the 5 micron range can also be

generated or can be the result of evaporation of

larger droplets. In medical changing rooms in

China higher viral loads have been noted.

Viruses are also being aerosolized by cleaning

the floor or from other surfaces.

Viral Load:

The viral load varies by individual and

activity.

A lusty super spreader singer was able to

generate many thousands of aerosols and infect

45 people in just two hours.

Minimum Infectious Dose:

There are reports that only 10 viral particles

is enough to cause an infection.

Other views are that it generally

requires a large number of particles over a

period of time. Since large cough or sneeze

droplets don’t travel far, social distancing is

therefore the best way to avoid infection.

However, if small numbers of airborne viruses

can cause an infection then a whole different

approach is needed.

Life of Virus:

The virus is known to remain viable for hours in

the air and for days on various surfaces.

Virus Rejuvenation from Dormancy:

It has now been documented that viruses are not

necessarily dead but just dormant as they travel

through the air. They can then penetrate the

lungs where the moisture revives them.

Creation of Aerosols from Viruses Leaving

Surfaces:

There are numerous cases tracking aerosols which

were originally on surfaces such as floors or

clothing.

Mask Factors

Efficiency of Various Masks in Removing Viruses:

Masks vary in efficiency depending on the

media and the fit. Viruses average 120 nm

in diameter but can be entrained in droplets

larger than 300 nm. In general the efficiency

improves with more media which means higher

pressure drop. The meltblown media used with

most N95 masks is electrostatically charged

which improves capture efficiency.

The pressure drop impacts breathability. It

increases as the square of velocity. So where

there is lots of leakage such as the surgical

mask with the gap below, the actual pressure

drop is much lower than 2.5 Pa. this is because

much of the air is bypassing the media. It is

clear that surgical masks with gaps do not

remove a big percentage of small particles.

Most homemade masks are even more

inefficient.

In some cases a heavy cotton fabric is by

itself quite efficient but with high resistance

it will cause more air to bypass the mask. The

takeaway is that the masks being worn by the

public do not protect against virus aerosols.

Table 1. Filtration Efficiencies of Various Test

Specimens at a Flow Rate of 1.2 CFM and the

Corresponding Differential Pressure (ΔP) across

the Specimens

|

flow rate: 1.2 CFM |

|||

|

filter efficiency (%) |

pressure differential |

||

|

sample/fabric |

<300 nm average ± error |

>300 nm average ± error |

ΔP (Pa) |

|

N95 (no gap) |

85 ± 15 |

99.9 ± 0.1 |

2.2 |

|

N95 (with gap) |

34 ± 15 |

12 ± 3 |

2.2 |

|

surgical mask (no gap) |

76 ± 22 |

99.6 ± 0.1 |

2.5 |

|

surgical mask (with gap) |

50 ± 7 |

44 ± 3 |

2.5 |

The analogy can be made between a garden house

and a rainstorm.

If you only want to remove large cough droplets

it is as easy as dodging a garden hose wielded

by a baby.

If you want to stay dry in a major storm

that is very challenging.

Various mask media options:

Surgical masks are made mostly with

meltblown polypropylene.

The meltblown is sandwiched between two

layers of spun bond media. There is an

electrostatic effect which improves on the

already high efficiency due to the fine fiber

matrix. There are some new meltblown designs

with claims of even higher efficiency at a given

pressure drop.

There are a number of alternative materials

which are now available commercially. They

include nanofiber membranes which are claimed to

have higher efficiency at a given pressure drop.

They are also washable. The media is

available in large quantities.

In the case of Cummins the offering is

based on media originally designed for filtering

engine air intakes. In the case of Ahlstrom it

is the use of surgical drapes. Berry is another

supplier diverting media used from other

applications.

Efficiency:

Some of the newly available media has

efficiencies rated at N99 or better. 3M already

offers a range of options higher than N95 using

meltblowns.

The question of a carbon layer and its

impact on efficiency also needs to be addressed.

Wash ability:

N95 masks with meltblown media can be

decontaminated with UV light, H2O2 , or other

means. Battelle reports ten time successful

reuse of masks decontaminated with H2O2.

Masks made with membrane materials can be

washed by various means and reused many times.

This reuse ability results in a better

tight fitting mask with an affordable cost per

use.

Efficiency reduction over time or with washing:

The support structure as well as the mask media

can deteriorate. The ability to separate the

media and support structure means that the

structure can provide longer term use.

Mask Fit:

The mask fit is critical to providing

protection. The more expensive reusable masks

can provide that fit.

Comfort:

N95 masks without valves but with a tight fit

are uncomfortable to wear for long periods. The

medical worker can endure the discomfort for a

shift but it is unrealistic to think that

people will wear N95 tightfitting masks

without valves throughout the day without

serious negative impacts.

Breathability and oxygen deprivation:

With a tight fitting N95 mask the quantity of

air inhaled is down as much as 25%.

Some CO2 is re-entrained in the new

breath. Two Korean 14 year olds

who were required to run in 1000 meter

tests with their masks on died last month on the

track.

The government has since suspended the

requirement.

Valve options:

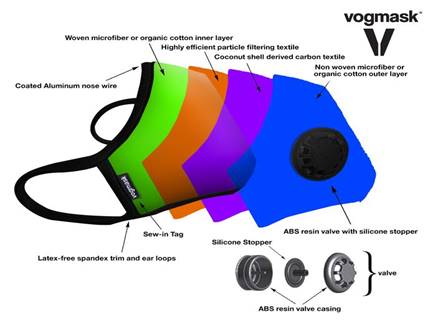

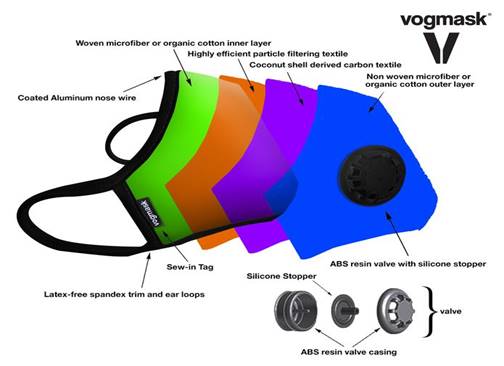

There is a large industry which has flourished

for many years. Masks with valves are purchased

by those wanting

to protect themselves from air

pollutants. In China there are Vogmask stores

where all they sell are dozens of varieties of

highly efficient designer masks.

They are equipped with one way valves

which allow the air to be exhaled through the

valve.

Millions of people have been wearing these valve

masks to protect themselves without concern

about their potential contamination of others.

Why is this not an important model for us to use

going forward?

Killing as well as capturing viruses:

A number of media designs incorporate silver or

other materials which will kill bacteria and

viruses.

Wearer factors

Age and immune response:

The use of masks by the elderly is conditioned

on the breathability.

It is unlikely that anyone with reduced

lung function or heart problems could wear an

N95 mask without a valve. Shouldn’t the type of

mask be dictated by this need? Should the

elderly be deprived of efficient masks because

valves are prohibited?

Sacramento says:

Masks with valves are prohibited.

Let’s consider mask recommendations by

segment and not as one.

Other medical conditions:

Those with impaired immune systems can probably

justify an N99 Mask and tight fit. This will

require use of a valve. The tight fit is also a

function of the valve. If you are blowing air

out around the edges of the mask you tend to

expand the opening.

Lung function:

The lung functions vary among individuals

creating an important variable in mask

selection.

Activities:

Any job function involving physical labor

including many meat processing jobs needs to

take into account the importance of wearing a

mask which does slow down oxygen intake.

Environment

Virus load:

The wearing of masks can be tailored to the

viral load and therefore the risk.

There is a movement to develop a N-80

mask which would be less efficient than the N95

but more efficient than the typical surgical

mask. Individuals could have all three mask

options available.

They could decide where it is most

appropriate to not wear a mask or to wear the

N80 or N95.

Percentage of aerosols:

The danger at any

point in time is a function of the

percentage of the total viral load which is in

the form of aerosols.

Humidity:

In general higher humidity deters the virus when

it arrives. The virus travels shorter distances

in humid air than in dry air where the droplet

size is smaller.

Air Flow Patterns:

The viral load is in part determined by air

flow. This important subject is dealt with in a

separate analysis.

Benefits of capturing other contaminants:

The coronavirus pandemic will subside at some

point in time. There will be uncertainty about

when and if it will return. Wearing an N90 mask

may become as much a habit as drinking bottled

water. Everyone is subjected to high air

pollution levels at some point in time during

the year. In some countries this is a daily

occurrence. But even in others the mask will be

justifiable. St Louis was meeting its

particulate ambient emission goals and was

assumed to be meeting its toxic metal goals

which had been shown to track the total

particulate. However, when the city installed

monitors to directly measure toxic metals, they

found spikes on days when the wind blew from the

direction of a lead refinery.

Hospital acquired infections cause 1.7 million

illnesses and 99,000 deaths per year in the U.S.

Patients would be well served to wear N95

masks

Face Mask Performance Articles in Previous

Alerts

Silicon Based Membrane for Masks has Efficiency

and Other Advantages

Researchers funded by King Abdullah University

of Science and Technology

have developed a membrane that can be attached

to a regular N95 mask and replaced when needed.

The filter has a smaller pore size than normal

N95 masks, potentially blocking more virus

particles.

N95 masks filter about 85% of particles smaller

than 300 nm, according to published research.

SARS-CoV-2 (the coronavirus that causes

COVID-19) is in the size range of 65–125 nm, so

some virus particles could slip through these

coverings. Also, because of shortages, many

health care workers have had to wear the same

N95 mask repeatedly, even though they are

intended for a single use. To help overcome

these problems, Muhammad Mustafa Hussain and

colleagues wanted to develop a membrane that

more efficiently filters particles the size of

SARS-CoV-2 and could be replaced on an N95 mask

after every use.

To make the membrane, the researchers first

developed a silicon-based, porous template using

lithography and chemical etching. They placed

the template over a polyimide film and used a

process called reactive ion etching to make

pores in the membrane, with sizes ranging from

5–55 nm. Then, they peeled off the membrane,

which could be attached to an N95 mask. To

ensure that the nanoporous membrane was

breathable, the researchers measured the airflow

rate through the pores. They found that for

pores tinier than 60 nm (in other words, smaller

than SARS-CoV-2), the pores needed to be placed

a maximum of 330 nm from each other to achieve

good breathability. The hydrophobic membrane

also cleans itself because droplets slide off

it, preventing the pores from getting clogged

with viruses and other particles.

https://pubs.acs.org/doi/full/10.1021/acsnano.0c03976

Fibre Extrusion Technology Says There May Be

Better Answers Than Polypropylene for Meltblowns

Fibre Extrusion Technology (FET), a UK-based

specialist in process solutions and equipment

for the manmade yarns and fiber extrusion

industry, has received unprecedented inquiries

about its nonwoven meltblowing systems since the

onset of the coronavirus crisis.

“We’re currently running trials, preparing

samples and defining specifications for

companies in Germany and Italy, as well as the

UK, and we could already have sold the lab line

we have here many times over,” said Managing

Director Richard Slack. “It’s primarily designed

for R&D and pilot scale applications, but trials

have proven it to be suitable for the low volume

production of critical meltblown face mask

materials. Some of the customers to whom we’ve

supplied similar lines have already pivoted

their production to this, which has generated

further interest.

“We feel, however, that we are ideally placed to

offer services to nonwoven companies who may be

exploring alternatives to polypropylene in

meltblown, due to our experience in working with

such a wide range of fiber types.”

FET’s meltblown system was originally developed

for companies looking to process high melt

viscosity medical grade resorbable polymers such

as polyglycolic acid (PGA), polylactic acid

(PLA) and polyhydroxl btyrate (PGH), mainly for

use in implantable products and other medical

devices.

The key applications for these fibers are in

hernia repair patches, staple reinforcement

buttresses, artificial skin, adhesion barriers

periodontal and ringival repair materials and

those for tendon and ligament repair.

“Our meltblowing system provides medical

companies and others dealing in such fibers with

a simpler processing route than other techniques

such as needle punching and a wide range of

structural and mechanical properties is

obtainable from batch production,” Slack said.

“There are also numerous options for

post-processing of the webs, by calendaring,

point bonding or lamination.”

Performance polymers such as TPU polyurethanes

and TPE thermoplastic elastomers are also

processed by a number of leading sportswear

companies on FET meltblown systems, while

engineering polymers such as ABS and PEEK, as

well as polycarbonate and halogenated polymers,

are other possible raw materials.

It is in the area of sustainable resins,

however, that FET believes much more can be

achieved.

Meltblown polypropylene nonwovens are the

critical component of the face masks needed for

Covid-19 frontline workers and their scarcity on

the open market has in part been the reason for

the reported shortages around the world.

An estimated 40 million face masks and other

disposable nonwoven-based PPE items are

currently estimated to be being consumed each

day, amounting to a daily 15,000-ton mountain of

waste — much of which must be incinerated.

“We’ve done a lot of work with sustainable

polyamides and polyesters, as well as with PHAs

and a range of of PLAs,” Slack says. “In the

longer term, there has to be a more sustainable

option than polypropylene in these products and

the opportunity to explore potential

alternatives — drawing on the know-how from the

extensive body of tests and trials we’ve carried

out in the past, as well as the machines run

commercially by our customers — is something I

believe makes us pretty unique in the services

we can offer nonwovens manufacturers.

Conventional meltblown and spunbonded systems

are usually designed for high capacity systems

and are not suitable for product development, he

adds.

“They consume high quantities of materials and

as a consequence are not suitable for

development work with high value materials or

for niche applications. They also rely on

specially formulated low viscosity polymers

which is a further limitation which does not

apply to us.

In processing finer filaments, FET has achieved

structures with average mean filament diameters

of 1.68 microns and 58% of between 0.5 to 1.5

microns, in web thicknesses of 37 microns with

bulk density of 98 mg/ml and porosity of around

92%.

FET’s system is designed for the processing of

pure polymer with no need for processing aids or

additives.

“A wide range of structural and mechanical

properties are obtainable, with numerous options

for post-processing of the web, such as by

calendaring, point bonding or lamination,”

Richard Slack concludes. “More effective and

sustainable PPE solutions could well be achieved

through further product development.”

NXTNano has Nanofiber Media Available for Face

Masks

A recent independent test by a mask supplier

showed high efficiency for media made by NXT

Nano. The company currently has some capacity

available for manufacturing N95 rated face mask

material. However they released this statement

“Please understand this situation is fluid, and

that as COVID-19 continues we expect this

capacity to fill”.

Materials are nanofiber coated PET in ranges

from 29 to 70 GSM depending on the needs of

individual manufacturing lines.

In 2019 NXTNano, commenced

installation of its third HYPR-Spun Nanofiber

production line, bringing its annual capacity to

above 60 million square meters of high

efficiency air filtration media. Like NTXNano's

existing production lines, the newest equipment

will facilitate high volume nanofiber

manufacturing up to a maximum roll width of 2.15

meters.

“As we continue to see very strong demand in

nanofiber air filtration medias as well as our

apparel, medical, and microfiltration business

segments, we felt it was critical to keep

capacity ahead of demand so our customers can

continue to count on the fast order turns they

have become accustomed to,” says director of

sales Andrew McDowell.

Tustar Teams with Neatrition to Introduce High

Efficiency Masks to the U.S. Market

With the help of Ann Arbor, Michigan-based TusStar,

Chinese nanotechnology company Neatrition is

introducing new KN95 safety masks to the U.S.

market.

These easy-to-clean, multiple-use masks will

shield users from respiratory droplets and other

particulate matter during the current COVID-19

crisis and beyond.

Neatrition collaborated with Tsinghua

University, a major research university

in Beijing, to develop and create these new nano

medical masks that offer several advantages over

traditional medical masks. Made in labs

in China and overseen by academic researchers to

ensure clean standards and a top-of-the-line

product, the Neatrition KN95/NMV95 masks have

a unique micro-nano sharkskin structure and

bacteriostatic features that not only block

aerial droplets from getting in, but also

quickly kills viruses attached to the surface of

the mask. U.S. Lab testing is currently underway

for the anti-virus feature in which a virus will

become inactive, degenerate and die within 1

minute on the surface of the material.

These advanced protection devices feature a

strong droplet surface coating that allows the

masks to last up to 10 times longer. The masks'

soft sewn stretch knit ties and carefully

crafted inner mask design provides a comfortable

fit that is easy to wear for long stretches and

is exceptionally breathable.

Traditional protective masks use material that

can only be used once and only isolate droplets

from the air," said TusStar President Frank Ni.

"Unfortunately, many medical professionals and

mask wearers are then still infected by the

virus even after using these traditional masks

because the virus is still alive on the outside

surface."

A 5-mask package sells for $32, plus tax and

shipping. Quantities of 500 masks are available

at a discounted rate of $2,800.

Beijing Neatrition Technology Co., Ltd. was born

in Tsinghua University. It is a new material and

technology company integrating R & D, production

and sales (Neatrition has developed

superhydrophobic technology. The series products

mainly cover (super) hydrophobic nanomaterials,

which are waterproof, dustproof, snowproof,

oilproof, etc. Neatrition, as a frontier science

and technology enterprise in Zhongguancun, is

committed to solving the surface cleaning and

maintenance of all related objects for

industrial and other users, the efficiency of

its masks are compare to traditional N95-N100

masks.

|

Neatrition® nano medical mask |

Traditional medical mask |

Filtration Efficiency |

Virus survival time on the surface |

||

|

Test with NaCl particles |

Test with oil particles |

Neatrition® |

Traditional medical mask |

||

|

Neatrition® NM95(can be reused up to 10 times) |

KN95(can be reused up to 3 times) |

>90-95% |

-- |

<2min |

>2d |

|

Neatrition® NMV95(can be reused up to 20 times) |

N95(can be reused up to 3 times) |

>95% |

-- |

<2min |

>2d |

|

Neatrition® NM100(can be reused up to 20 times) |

N100(can be reused up to 3 times) |

>99.9% |

-- |

<2min |

>2d |

|

Neatrition® NTV100(can be reused up to 20 times) |

None |

>99.9% |

>99.9% |

<2min |

>2d |

Due to the anti-bacterial qualities the masks

can be stored and reused. One regimen is to

rotate masks every three days to insure

inactivation of the virus which was retained on

the mask surface.

Sciessent

Antimicrobial Used in Hanesbrands Masks

Sciessent has partnered with both healthcare and

non-healthcare manufacturers to develop and gain

regulatory clearance for masks containing Agion

Antimicrobial for use in healthcare settings.

Sciessent has helped two suppliers obtain

approval for the anti-microbial masks—one with

a traditional medical device manufacturer

following the severe acute respiratory syndrome

(SARS) outbreak in the early 2000s, and another

this year with a manufacturer from outside of

the medtech industry—comparing and contrasting

the two from an FDA regulatory process

perspective.

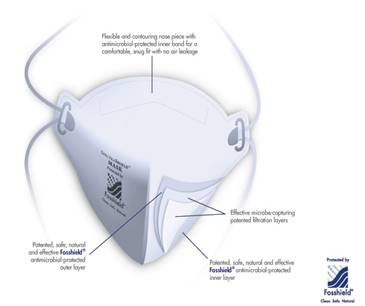

Following the 2003 SARS outbreak, medical device

manufacturer

Nexera made the decision to develop a N95

respirator mask constructed from Foss

Performance Materials’ Agion Antimicrobial

treated polyester fiber. As a medtech company,

Nexera had experience with FDA review for its

devices so it understood what the process

entailed. The company looked to Sciessent as its

supply partner to help with regulatory

considerations related to the antimicrobial.

Because Nexera had developed the mask in

response to SARS, as a product that could help

in future respiratory virus outbreaks, the

Nexera and Sciessent teams had ample time for

pre-planning prior to FDA submission. This

included the opportunity to develop data to

support the mask’s antimicrobial claims. Working

together, the teams successfully obtained FDA

clearance for Nexera’s SpectraShield 9500 N95

respirator mask, and later leveraged additional

data to secure an updated 510(k) with cleared

claims to inactivate viruses by 99.99 percent in

five minutes.

Sciesent also worked with Hanesbrands. While the

FDA is leveraging its Emergency Use

Authorization (EUA) to accelerate the timeframe

for clearance of products to address the

COVID-19 crisis, and this is certainly a benefit

to companies producing PPE, Hanesbrands still

had to meet the agency’s requirements. Sciessent

served as a collaborative partner in these

efforts with medical device expertise, a wealth

of data, and extensive experience in navigating

the FDA’s regulatory review pathway.

Unlike the premeditated work with Nexera to

develop a mask following the SARS outbreak

nearly two decades ago, work with Hanesbrands

required that the team leverage existing

knowledge and experience to quickly fill-in

various information gaps. Instead of developing

a product from the ground up, Hanesbrands was

repurposing its knitted cotton fabrics treated

with Agion Antimicrobial to develop its masks.

Sciessent supported Hanesbrands in their

interactions with FDA. Given the urgent need to

address the PPE shortage, it appeared

communication was far more open and frequent

with the agency under the EUA directive. The

correspondence and exchange of information

between Hanesbrands and FDA moved quickly. In

this circumstance, the FDA did not clear

specific efficacy claims; in fact, the agency

said no efficacy claims could be made.

Having worked closely with the FDA with Nexera

for its N95 mask and with other medical device

manufacturers for their products, Sciesent was

able to pivot quickly and apply its

understanding of the regulatory process to the

Hanesbrands situation. It was also able to

leverage the data on safety and efficacy,

including viruses from the Nexera mask’s second

510(k) clearance, to help fast track the

Hanesbrands mask clearance. As a result, FDA

cleared Hanesbrands’ mask in a matter of days,

enabling the company to quickly transition its

operations to relieving the PPE shortage.

Teho Filter Using Ahlstrom Media for N88 Masks

in Finland

Ahlstrom-Munksjö is supplying facemask material

from its plant in Tampere to Teho Filter for the

assembly of masks. The masks will be available

in May-June in the stores of Finland based

retailer S Group.

The filtration efficiency of the face mask

material of 88% has been verified by VTT

Technical Research Centre of Finland. It is

substantially higher than the roughly 20-40%

efficiency of masks made from cloth; the company

claims. The filtration efficiency of a

mechanical filter media remains intact over time

compared to electrostatically charged materials

the efficiency of which may decrease in humid

conditions, Ahlstrom-Munksjö adds.

“We work with determination in order to enhance

the supply of face masks for consumers in

Finland. At the same time, we are further

supporting the reopening in Finland once the

corona pandemic restrictions loosen,” states

Otto Kivi, Sales Manager at Ahlstrom-Munksjö’s

Filtration business.

The company announced in April that it would

start the production of facemask materials in

Tampere, where its plant is capable of producing

material for more than 10 million masks in the

short-term and has the ability to increase

capacity to about 30 million masks per month.

Earlier in May, the company announced a similar

co-operation on facemask supply with other

Finnish players.

” We are also very pleased about the continued

product development in Tampere: our production

now meets the filtration efficiency requirements

of surgical face mask materials. Currently, we

are working together with our customers to

develop a product that meets the European

Standard EN 14683 for surgical masks. The

availability of various protective gear is

vitally important,” Kivi continues.

Ahlstrom-Munksjö has long-term and in-depth

knowledge in the production of protective

materials for the healthcare industry. Due to

the coronavirus pandemic, the company has

increased its offering in protective fabrics and

expanded the production of face mask materials

globally to support the healthcare sector.

Russian Scientists Develop Nanofibers for Masks

A group of scientists from Russia’s Krasnodar

Region invented

a nanofiber material for production of medical

masks and respirator disposable filters that is

more effective for prevention of the coronavirus

spread than normal cloth,

Dmitry Lopatin, a team representative, told TASS

recently.

"We have begun our research in late March:

kerosene soot particles have the same size as

the coronavirus. We tested both the normal cloth

used in mask production and our nanofibers for

absorption. Currently, we are looking into two

possible applications of our nanofibers for

coronavirus prevention: production of medical

masks and disposable respirator filters,"

Lopatin said. Dmitry Lopatin is a graduate of

the Kuban State University. The group conducts

its research in the Krasnodar Region’s Goryachy

Klyuch.

O2 Nano Mask is Low Pressure Drop, Efficient and

Reusable

Viaex Technologies, a material science startup

and laboratory, has been researching

nanomaterials and developing their own products

for over six years. They have collaborated with

DaD Sewing House, a network of local

manufacturers that provide employment

opportunities to skilled craftspeople in San

Francisco, to create the O2 Nano Mask.

Distributed under O2

Brands,

the O2 Nano Mask was created in April 2019 as a

high-quality pollution mask, and this year, its

production was increased to meet the demand of

communities and healthcare facilities for protective

masks for

health workers and people affected by Covid-19.

O2

The O2

Nano Mask is sold at $35.99 and

comes in medium and large sizes.

The mask consists of two components: the

reusable skin and the replaceable filter.

Each filter features three layers: two layers of

PET and one embedded with nanofiber material.

The fibers are on the order of 85 ± 20 nm in

diameter. This nanoscopic morphology creates

uniquely small pores and drastically increases

the membrane surface area while leaving open-air

travel paths in 99% of the membrane volume.

The O2 Nano Mask’s filter component stops 99% of

PM2.5 particles, including dust and other air

pollutants; pollen; dander and other allergens;

bacteria and other germs; harmful gases; smoke

(including from wildfires) and other fumes with

its five-layer protection and hypoallergenic

hydrophobic nanofilter. The filter media used

has achieved 99% particle removal efficiency

based on EN143 European certification standards

and third-party testing.

The mask’s outer shell component can last for a

long time. The mask is machine washable and

tumble dryer safe. It’s intricately constructed

to be worn time and time again. The filters are

long-lasting depending on the level of pollution

and are also fully recyclable. Each O2 Nano Mask

filter can last from eight hours to 20 days

(with light exercise in a moderate AQI

environment).

Cambridge has an Efficient and Comfortable Mask

but with Valve

The pro mask uses a unique triple filter system

which has been tested by Nelson and reaches N99

efficiency levels.

The first layer of the filter system catches

larger pollution particles such as dust and

PM10. It’s then backed up by the Three-Ply Micro

Particulate which stops nearly 100% of smaller

particulate matter such as PM2.5 and PM3.0.

The

inner filtration layer is made from 100% pure

activated carbon cloth, originally developed by

the UK Ministry of Defense for chemical,

biological, and nuclear warfare protection.

The carbon filter is treated with silver to

ensure 99% of harmful pathogens are removed and

killed. The filter material is comprised of a

series of activated carbon filaments, each about

2,000 nanometers in diameter. Each filament is

many times smaller than the typical grain size

in standard carbon materials, making the rate of

adsorption of pollutant gas much faster and

therefore more powerful. It also means that

bacteria and viruses are drawn to the filament

surface much more efficiently, because there is

so much more available surface than in a

granular carbon.

The high number of filaments – spun into a yarn

and then woven into cloth – makes the speed of

adsorption extremely fast in a material that is

still easy to breathe through. Not only are

molecules such as pollutant gases and endotoxins

quickly adsorbed into the pores from a much

wider area, but the Van der Waals forces also

attract and immobilize on the filament surface

much larger particles including bacteria, which

often have a negatively charged membrane.

Together with the anti-bacterial silver added to

the filament surface, the activated carbon cloth

traps the bacteria and draws out the gel-like

cytoplasm inside – killing it and preventing

infection.

Cambridge uses

British military technology developed for

chemical, nuclear, and biological warfare in the

mask that’s manufactured in the UK. But the

masks are assembled in Indonesia and China.

Masks Performance Comparison

|

Fashion friendly |

✔ |

✘ |

✘ |

|

Suitable for

children |

✔ |

✘ |

✘ |

|

More

environmentally

friendly

long-lasting

mask |

✔ |

✘ |

✘ |

|

Comes with high

quality

cardboard for

safe and easy

carrying |

✔ |

✘ |

✘ |

|

Adjustable

earloops |

✔ |

✘ |

✘ |

|

Blocks over 99%

of viruses and

bacteria |

✔ |

✘ |

✘ |

|

Filters gas

pollutants such

as Ozone and

oxides |

✔ |

✘ |

✘ |

|

Mask filter life |

200-300 hours

(3-6 months) |

8-10 hours |

8-10 hours |

|

Cost per hour of

use (USD) |

$0.08c |

$0.23c |

$0.03c |

Draeger has Long Term Contract to Deliver N95

Masks to HHS

The U.S. Department of Health and Human Services

(HHS) issued an award to Dräger for the supply

of National Institute of Occupational Safety and

Health (NIOSH) approved N95 respiratory

protection masks at the end of March. The

contract is part of the recent government

announcements concerning the supply of masks. As

part of the contract Dräger plans to increase

U.S. domestic production of the masks and expand

its manufacturing footprint over the course of

the contract. Deliveries will take place over

the next 18 months with a focus on accelerated

supply wherever possible.

“Respiratory protection has been at the core of

our capabilities for over 110 years. Our N95

mask design offers superior comfort and

breathability and is certified to the NIOSH

standard for particle respiratory protection,”

said President and CEO for Dräger in North

America, Lothar Thielen. “This contract comes in

addition to the ongoing work we are doing to

protect frontline personnel in the fight against

the pandemic. We are humbled to be able to

support healthcare professionals and first

responders with our Technology for Life, which

spans both healthcare and safety applications.

In addition we are proud to further increase our

U.S. investments and manufacturing base in

support of this contract.”

Dräger is an international leader in the fields

of medical and safety technology. Our products

protect, support, and save lives. Founded in

1889, Dräger generated revenues of almost EUR

2.8 billion in 2019. The Dräger Group is

currently present in over 190 countries and has

more than 14,500 employees worldwide

CDC Approves Powered Air Purifying Respirators

NIOSH-approved respirators are available in many

types, models, and sizes from many manufacturers

for a wide variety of uses in many occupational

settings. The most common types of respirators

in healthcare are N95 filtering facepiece

respirators (FFRs), surgical N95 FFRs, and

PAPRs.

Of these three options, many healthcare

practitioners are the least familiar with PAPRs.

A PAPR is an air-purifying respirator that uses

a blower to force air through filter cartridges

or canisters and into the breathing zone of the

wearer. This process creates an air flow inside

either a tight-fitting facepiece or

loose-fitting hood or helmet, providing a higher

assigned protection factor (APF) than the

reusable elastomeric non-powered air-purifying

half facepiece (half mask) or N95 FFRs. A PAPR

can be used for protection during healthcare

procedures in which HCP are exposed to greater

risks of aerosolized pathogens causing acute

respiratory infections.

A PAPR may have a tight-fitting half or full

facepiece or a loose-fitting facepiece, hood, or

helmet. It has an OSHA APF of at least 25 for

loose-fitting hoods and helmets, 50 for

tight-fitting half masks, and 1,000 for full

facepiece types and some loose-fitting hoods and

helmets where the manufacturer’s testing has

demonstrated an APF of 1,000.

CDC has published recommendations for HCP

respiratory protection and of commonly used

NIOSH-approved, FDA-cleared, single-use

filtering facepiece N95 surgical respirators.

Properly fitted FFR and half facepiece reusable

elastomeric respirators are expected to reduce

exposures to one-tenth of the concentration that

is in the air, based on OSHA’s APF of 10 for

these respirator types. All PAPR APFs exceed the

APF of 10 for N95 FFR or elastomeric half

facepiece respirators.

PAPRs reduce the aerosol concentration inhaled

by the wearer to at least 1/25th of that in the

air, compared to a 1/10th reduction for FFRs and

elastomeric half facepiece air-purifying

respirators. OSHA assigns an APF of 1,000 to

some PAPRs with hoods or helmets. However,

employers must have evidence provided by the

respirator manufacturer that testing of these

respirators demonstrates performance at a level

of protection of 1,000 to receive an APF of

1,000. Absent such evidence, PAPRs with

loose-fitting helmets or hoods have an APF of

25. When used properly, PAPRs provide increased

protection and decrease the likelihood of

infection transmission to the wearer as compared

to FFRs and half face reusable elastomeric

respirators.

A variety of NIOSH-approved PAPR designs are

available. Examples include those with

tight-fitting facepieces and loose-fitting hoods

or helmets, blower styles, battery types (e.g.,

Lithium ion, Nickel-Metal hydride, Nickel

Cadmium) or over-the-counter disposable

batteries, and high efficiency (HE) filters or

filter cartridges. HE filters are 99.97%

efficient against 0.3 micron particles. A PAPR

may have adjustable air flow rates for added

comfort and a range of cartridge protections

some of which are solely for particulates (HE

filters) and others which also protect against

chemical gases and vapors that can be used to

help protect against hazards associated with the

handling of certain hazardous drugs and

cleaning/disinfecting operations. The

substantial PAPR product diversity provides

flexibility to customize protection needed in a

healthcare setting.

IQ Mask Uses HEPA Grade Filtration Media

IQAir Mask features a unique

exhaust valve design with an ultra-thin

valve membrane for low air resistance and

immediate air exchange. Many air pollution masks

use ineffective material that wears out quickly

due to moisture build-up and high filter

material resistance – IQAir Mask ensures an even

exchange of inhaled clean air and exhaled

breaths while reducing moisture and CO2

build-up inside the mask to prevent drowsiness,

headaches, or loss of energy.

|

|

IQAir Mask |

|

|

|

|

General Features |

|

|

Air leak

protection |

SoftSeal

prevents air

leakage with

minimal pressure

on facial skin |

|

Filter media |

Melt-blow cage

(PE) |

|

Breathing valve |

FeatherValve for

CO2

release upon

exhalation |

|

Mask structure |

3D Filter Dome

for space

between media

and skin |

|

Sealant material |

Terylene

polyester fiber |

|

Product lifespan |

3-year

shelf-life

(recommended) |

|

Suggested time

for replacement |

When the mask is

broken, stained,

or the

respiratory

resistance |

|

Color |

White filter

material, gray

sealant fabric

and logo imprint |

|

Storage

temperature |

< 70% rel. H,

-4°F to 158°F

(-20°C to +70°C) |

|

Operating

temperature |

4° to 140° F

(-20 to +60 °C) |

A Mask is Not a Mask-Big Difference in

Efficiency and Fit

An analysis of mask filter media shows that

there are big differences between materials and

the fit of the mask.

Homemade masks can be quite efficient on

removing particles such as viruses but the

pressure drop is high. The fit of the mask means

as much as the media efficiency.

Details of the study are shown in an ACS

publication

https://pubs.acs.org/doi/10.1021/acsnano.0c03252

There is a need to evaluate filtration

efficiencies as a function of aerosol

particulate sizes in the 10 nm to 10 μm range,

which is particularly relevant for respiratory

virus transmission. The researchers carried out

these studies for several common fabrics

including cotton, silk, chiffon, flannel,

various synthetics, and their combinations.

Although the filtration efficiencies for various

fabrics when a single layer was used ranged from

5 to 80% and 5 to 95% for particle sizes of <300

nm and >300 nm, respectively, the efficiencies

improved when multiple layers were used and when

using a specific combination of different

fabrics. Filtration efficiencies of the hybrids

(such as cotton–silk, cotton–chiffon,

cotton–flannel) was >80% (for particles <300 nm)

and >90% (for particles >300 nm). The

researchers

speculate that the enhanced performance

of the hybrids is likely due to the combined

effect of mechanical and electrostatic-based

filtration. Cotton, the most widely used

material for cloth masks performs better at

higher weave densities (i.e.,

thread count) and can make a significant

difference in filtration efficiencies. Studies

also imply that gaps (as caused by an improper

fit of the mask) can result in over a 60%

decrease in the filtration efficiency, implying

the need for future cloth mask design studies to

take into account issues of “fit” and leakage,

while allowing the exhaled air to vent

efficiently. Overall,

the study

finds that combinations of various

commonly available fabrics used in cloth masks

can potentially provide significant protection

against the transmission of aerosol particles.

Table 1. Filtration Efficiencies of Various Test

Specimens at a Flow Rate of 1.2 CFM and the

Corresponding Differential Pressure (ΔP)

across the Specimens

|

flow rate: 1.2 CFM |

|||

|

filter efficiency (%) |

pressure differential |

||

|

sample/fabric |

<300 nm average ± error |

>300 nm average ± error |

ΔP (Pa) |

|

N95 (no gap) |

85 ± 15 |

99.9 ± 0.1 |

2.2 |

|

N95 (with gap) |

34 ± 15 |

12 ± 3 |

2.2 |

|

surgical mask (no gap) |

76 ± 22 |

99.6 ± 0.1 |

2.5 |

|

surgical mask (with gap) |

50 ± 7 |

44 ± 3 |

2.5 |

|

cotton quilt |

96 ± 2 |

96.1 ± 0.3 |

2.7 |

|

quilter’s cotton (80 TPI), 1 layer |

9 ± 13 |

14 ± 1 |

2.2 |

|

quilter’s cotton (80 TPI), 2 layers |

38 ± 11 |

49 ± 3 |

2.5 |

|

flannel |

57 ± 8 |

44 ± 2 |

2.2 |

|

cotton (600 TPI), 1 layer |

79 ± 23 |

98.4 ± 0.2 |

2.5 |

|

cotton (600 TPI), 2 layers |

82 ± 19 |

99.5 ± 0.1 |

2.5 |

|

chiffon, 1 layer |

67 ± 16 |

73 ± 2 |

2.7 |

|

chiffon, 2 layers |

83 ± 9 |

90 ± 1 |

3.0 |

|

natural silk, 1 layer |

54 ± 8 |

56 ± 2 |

2.5 |

|

natural silk, 2 layers |

65 ± 10 |

65 ± 2 |

2.7 |

|

natural silk, 4 layers |

86 ± 5 |

88 ± 1 |

2.7 |

|

hybrid 1: cotton/chiffon |

97 ± 2 |

99.2 ± 0.2 |

3.0 |

|

hybrid 2: cotton/silk (no gap) |

94 ± 2 |

98.5 ± 0.2 |

3.0 |

|

hybrid 2: cotton/silk (gap) |

37 ± 7 |

32 ± 3 |

3.0 |

|

|

|

|

3.0 |

The quilter cotton mask could have a capture

efficiency of less than 13%. This means that

these masks are not effective in combatting the

virus. Some of the fabrics which are effective

have a high pressure drop. Most important the

fit of the mask is a key factor. An N95 mask

with a gap is only 34% efficient on particles

less than 0.3 microns.

The advice about wearing masks tends to treat

all masks as equal.

In fact there is a world of difference.

W.L. Gore has a Number of Products it is

Developing to Fight COVID

Gore has engineered prototype reusable mask

covers to supplement clinicians’ primary face

masks.

These covers, developed by a cross-divisional

team, are made from a material that:

·

is a proprietary Gore high-flow filtration

laminate

·

provides greater than 99% aerosolized virus

particle protection

·

is water repellent yet air permeable, and

·

can be reused after autoclave or EtO

sterilization

This effort went from a product concept to

prototypes in less than one week. Gore currently

has prototypes being evaluated at a limited

number of U.S. facilities in COVID-19 outbreak

hot spots. Based on feedback from those piloting

the prototype, Gore intends to optimize the PPE

Protector design and then scale up production

for broader distribution.

Examples of other initiatives underway include:

·

Protective medical gowns, using fabric laminates

from current inventory

·

Universal filter cartridge prototypes for use in

respirators, hoods and ventilators that

incorporate Gore filtration materials intended

to provide N95 particulate protection

·

Disposable N95 respirators, using Gore

filtration laminates

N80 Masks Should be Worn by Three Billion People

Who are in Public Space Every Day.

In a conversation with Dave Rousse of INDA

earlier this week he talked about the N80

concept.

This gives a specific name to what he

believes will be a critical mission to assure

that everyone in a public space is wearing an

efficient mask. In our previous Alerts we have

written about the

Berry Development of a mask in this

quality range.

We further covered it in a Berry Profile.

LINK to Berry Power Points

We also reported earlier about Ahlstrom-Munksjö,

whose products Reliance SMS 200, Reliance SMS

300, Reliance Dextex 200 and Reliance

Dextex 300 have been declared compatible with

the French requirements for face masks used by

civil servants in contact with the public. The

material is typically used for the manufacture

of sterilization wraps for surgical instruments.

Reliance SMS 200 and Reliance SMS 300 have also

been tested compatible with the European

Standard EN 14683, meeting the performance

criteria of surgical masks.

This month the

company is producing

material equivalent to 100 million face

masks for civil servants in contact with the

public such as police officers, prison

administrators and social workers as well as

companies active in essential sectors such as

food, energy, water and waste.

“The attainment

of this long-term work for the selection of our

products represents a moment of collective pride

at Ahlstrom-Munksjö. Our medical business serves

the medical device market worldwide all year

round, and our agility and ability to innovate

makes us an ideal partner in critical

situations,” says Lionel Bonte, vice president

of medical business.

Modern Healthcare Corporation has N-80 Mask

Motex, manufactures disposable medical surgical

wound dressings and medical tapes as well as the

varied face masks in Taiwan. It has

plants located in Thailand, Shanghai and

Taiwan. They

have the certificates of ISO, CE, GMP.

and some items with US FDA510K approved. The

company was established in 1978 and has less

than 100 employees.

It offers N80 masks. This designation is being

used by those who are offering a mask for the

general population which is higher efficiency

than most masks being worn by the public but

would be 80% efficient on 0.3 micron particles

in contrast to the 95%

N95.

The original name of the company

was Huaxin Medical Materials. It

has won awards for a

new airtight protective

mask. The overall safety and

comfort of flat masks have

greatly improved. Chairman Zheng

said that the patented

technology has the advantages of

integrated design, fully

automated production, cost

competitiveness, etc., and can

be applied to various flat masks

on the market such as: dustproof

(protective) masks, activated

carbon masks, surgical bandage

masks ... I believe that we can

recreate the blue ocean business

opportunities in the mask market

and benefit the consumers.

Masks are Part of a Combined

Program to Reduce the Odds to

Near Zero

Ryanair CEO Michael O'Leary has claimed that if

everyone wore face masks on planes and public

transport, it would ''eliminate the risk of

spreading Covid-19 by about 98.5%''.

O'Leary, who wants to restart flights in July,

was speaking on BBC Radio 4's Today programme.

He called the government's plan to quarantine

travelers for 14 days "ineffectual" and

"unmanageable".

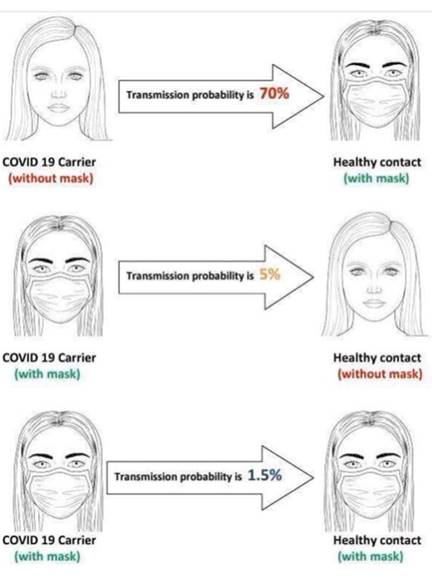

O'Leary said the 98.5% figure came from a study

by the Mater Hospital in Dublin.

This is over simplified because

the efficiency of each mask is

not specified. But if both are

wearing N95 masks the

probability should be reduced to

fractions of a percent.

This could be reduced to close

to 0 with partitioning.

There is already an air nozzle

above each passenger.

If this is directed

downward you have the ideal

cleanroom conditions of downward

laminar flow of HEPA filtered

air.

The avoidance of COVID-19 is a gamble but one where each safety measure keeps increasing the odds. If there is screening of passengers and temperature checks at the gate. The odds of sitting next to a COVID carrier are small. This would be increased further if passengers were tested for COVID before they boarded.

Airplanes are Relatively Safe with the Following

Guidelines

Joseph Allen, assistant professor of exposure

assessment science at Harvard, argues that

despite what you may think, “you don’t get sick

on airplanes more than anywhere else.”

Allen says airlines have, for many years, worked

to keep passengers safe from disease while they

travel.

“The ventilation system requirements for

airplanes meet the levels recommended by the

Centers for Disease Control and Prevention for

use with COVID-19 patients in airborne infection

isolation rooms,” Allen said

Midwest Textiles, Hollingsworth & Vose Partner

to Develop Homemade Facemask Kit

Midwest Textiles and Hollingsworth & Vose (H&V)

are collaborating on a new ready-to-sew face

mask kit for the general public. The new

collaboration between Midwest and H&V offers an

improvement to the everyday consumer by adding a

layer of Nanoweb FM to the mask.

Nanoweb FM is new filtration media made by H&V,

designed for use in homemade face masks.

“H&V is one of the world’s leading producers of