Coronavirus Pharmaceutical Solutions

June 3, 2020

·

Coronavirus vaccine would

create a market of up to $ 40 billion/yr

·

Single use closed systems can shorten the

timeline to a successful COVID vaccine.

·

Sanofi has New Closed System with Single-Use

Technologies:

·

In house manufacturing helping speedy

progression of mRNA COVID vaccine, says Moderna

·

Deciding on spare production capacity is

difficult

·

Will modular cleanroom design accelerate therapy

and vaccine production to fight COVID

·

Stringent environmental controls needed in

vaccine manufacturing

·

Do Moderna executives have

faith in their product?

·

Fauci defends comments relative to a vaccine

within 18 months

·

Challenge to prioritize COVID over other

clinical trials

·

“May be effective” is not the criterion for

widespread vaccine use

·

Pfizer says vaccine likely

available by end of October

____________________________________________________________

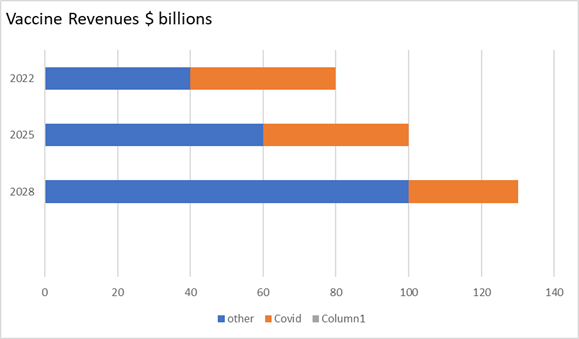

Coronavirus vaccine would create a market of up

to $ 40 billion/yr

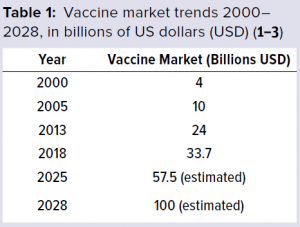

The global vaccine market has been growing

rapidly and thus has been attracting interest

and new players. The World Health Organization

(WHO)

has reported that from 2000 to 2013, the

vaccine market grew from 4 billion US dollars

(USD) to 24 billion USD (Table 1).Prior to the

coronavirus

market trends suggested that by 2028, the

value of the vaccine market was estimated to be

about 100 billion USD, growing at a compound

annual growth rate (CAGR) of 11.02%. And, more

than 120 new products are in development, 60 of

which are of special importance for developing

countries.

Assuming a reliable COVID vaccine is developed

for sale in 2021. Initial sales could be $40

billion dropping to $ 30 billion by 2028.

The suppliers of cleanrooms, bioreactors,

centrifuges, and other process equipment will be

challenged to provide the products and

construction services needed to meet the

requirements.

What role will closed systems, single use

systems, modular rooms, pods, RABS, isolators,

biosafety cabinet and other approaches play?

Will some be faster track options?

The mobile trailer or Pod approach offers the

fastest track but has disadvantages compared to

modular and stick built cleanrooms.

It is the most costly approach.

It is less adaptable to change mid

project.

With the variations and uncertainties

relative to COVID, this would be a problem.

There may be a need for process design

changes.

|

|

Stick built |

Modular

|

trailer |

|

Less space |

A |

A |

C |

|

Shortest time |

C |

B |

A |

|

Least cost |

A |

A |

C |

|

guarantee |

C |

A |

A |

|

Adaptable |

A |

A |

C |

|

Late change |

A |

B |

C |

|

Quality

|

C |

A |

A |

|

Predictability

|

C |

A |

A |

|

Compliance |

C |

A |

A |

|

Durability

|

C |

A |

A |

·

A most favorable B in betweenA

most favorable B in between

·

C least favorable

The markets for diagnostics and therapeutics

could be even bigger than for the vaccines.

How will this impact the availability of

products and services?

Single use closed systems can shorten the

timeline to a successful COVID vaccine.

The vaccine industry is challenged to develop

high-quality products at decreased cost and

within shortened timelines. The need to reach

the market first highlights the importance for

fast process development strategies and

techniques. Such pressures have driven the

vaccine industry to embrace innovative

technologies. In return, shortening process

development times will accelerate overall

vaccine product development timelines and

rapidly deliver safe and high-quality products

to a global market.

Some vaccine manufacturers face additional

difficulties. These include the need to work

with small batch sizes and varied product

portfolios.

Pandemic outbreaks that require rapid responses

from vaccine developers and use of highly potent

ingredients place large demands on cleaning

processes. Given such pressures, single-use

fill–finish assemblies can be an attractive

option for vaccine manufacturing facilities.

The biologics industry has been using single-use

technologies for over 10 years to the point at

which it can be considered mainstream in

bioprocessing, including in vaccine development

and manufacturing. Key advancements include

single-use bioreactors to disposable products

for final formulation and filling. A number of

vendors provide single-use bioreactors,

centrifuges, depth filters, column

chromatography systems, and bags for media

preparation and final formulation

Sanofi has New Closed System with Single-Use

Technologies:

Some single-use systems have been established in

process development and are making their way

into manufacturing. For example: Sanofi has

developed a closed, single-use process system

(from bench top to 100-L scale process) for a

serum-free, live viral vaccine product, with

close collaboration between suppliers and the

vaccine industry. In addition, staff found the

operations of the closed system much easier to

manage than the previous system. Because it

produces higher yields, the new system required

fewer production runs. And the use of disposable

technologies ensures that sterility is

maintained throughout the process.

The net result was an overall reduction in

development time and manufacturing costs.

Facility turnover was easier and faster with

this than with the previous system, and

validation of fixed assets such as stainless-

steel fermenters, tanks, and centrifuges was no

longer necessary.

Application of single-use technologies provided

opportunities to reduce fixed costs, amount of

equipment, and cleaning validation, while

increasing facility and process flexibility and

accelerating process development time.

Disposables play a key role in addressing the

industrial challenges associated with developing

high quality processes while driving down

operational costs.

In house manufacturing helping speedy

progression of mRNA COVID vaccine, says Moderna

Moderna Therapeutics believes its Norwood,

Massachusetts manufacturing plant is a

“competitive strategic advantage” in the race to

develop and scale-up a vaccine against COVID-19.

Moderna released data from a small Phase I study

of its candidate mRNA-1273 last week. The

trial, conducted

by the

National Institute of Allergy and Infectious

Diseases, showed signs that the candidate

elicits antibodies at levels comparable to those

found in the blood of dozens of patients who

have recovered from COVID-19, caused by the

novel coronavirus (SARS-CoV-2).

Now the firm says a

Phase II study enrolling hundreds of patients is

expected to begin “shortly,” and a Phase III

study enrolling thousands is planned to start in

July, making it the frontrunner in the race to

develop a vaccine against the infectious

disease.

According to CEO Stéphane Bancel, Moderna’s

manufacturing strategy – and specifically its

inhouse facility in Norwood, Massachusetts –

played a major part in the speed of development

and will help expedite the candidate’s

progression through the clinic and beyond,

helping the firm achieve its goal of producing a

billion doses a year.

“I believe it is a competitive strategic

advantage of a company, having our own

manufacturing facility from raw materials to

shipping vials to clinical trials,” he told

stakeholders during a conference call yesterday.

If Moderna had been forced to use contract

development and manufacturing organizations (CDMOs),

“we could never have been so fast,” he

continued, adding that while four or five

companies could make the mRNA for the firm,

there would have been delays in waiting for

empty slots and tech transfers, as well as

losing on Moderna’s own determination to

expedite this project.

“Being in Norwood, with our own team on

equipment, on facility, allows us to tell the

team this is very important; this one needs to

move through the system much faster than usual,

and people knew the importance of this as virus

was spreading, all determination just grew

stronger with the day.”

The 200,000 square-foot Norwood site, which

opened in July

2018, has

capacity to develop materials for preclinical

toxicology studies, Phase I and II clinical

development programs, and the ability to

manufacture, test and run fill/finish operations

for its mRNA development candidates.

Thus to scale-up mRNA-1273, Moderna has

also inked a deal with Lonza with

initial manufacturing planned to take place at

the CDMO’s site in Portsmouth, New Hampshire,

with a second phase planned at its site in Visp,

Switzerland.

“The partnership with Lonza helps to be able,

assuming a 50-microgram dose, to potentially get

to one billion dose per year,” said Bancel. The

deal will increase capacity ten-fold for the

COVID candidate, though Bancel suggested the

firm would have preferred to have done all the

production inhouse if it had the option.

Deciding on spare production

capacity is difficult

David Dodds of Dodds and

Associates has weighed in on the

wisdom of in-house production.

Any in-house production facility

is an advantage – of course. It

is obvious – and has been

throughout history – that any

degree of vertical integration

on an immediately local,

physical basis provides a large

benefit – when it is valued in

hindsight, during a crisis.

But there is no good method for

assigning a dollar-value to the

intangible benefit of having

that facility immediately

available (and so empty and

waiting at all other times –

possibly for years when there is

no need for it), or to the

equally intangible liabilities

of delay and inconvenience of

dealing with a third-party,

especially one several time

zones distant. This is

completely missing from current

methods of cost-assessment and

IRR or ROI calculations.

Dodds says we need a method of valuing high

advantage/low use assets and the avoidance of

crisis, as well as the disadvantage of

constant-but-trivial inconvenience and delay in

day-to-day operations. At present, we seem to be

unable to do this.

The intangible value of contingency,

flexibility, redundancy, and robustness have

been the casualties of the last few decades of

cost-savings

Will modular cleanroom design accelerate therapy

and vaccine production to fight COVID

This subject was addressed by Mitchell Gonzales

of AES Clean Technology in Cell & Gene

Nowhere in the product development timeline does

speed to market matter more to patients’ needs,

or to the investors who make these treatments

possible than when life-altering medicines,

therapies, and devices reach the end phase of

clinical trials.

For example, existing and new cell and gene

therapies are verging on “curative” treatments,

making speed to patients’ imperative for human

conditions inducing severe and irreparable

consequences in the absence of available

treatments. Initial cell and gene therapy

commercial products (e.g., Luxturna, Zolgensma,

Yescarta) have elevated the impact and success

of these treatments.

The article documents why modular cleanroom

systems are being increasingly chosen over a

conventional construction approach due to their

accelerated design and installation schedule

advantages, as well as their reduced job-site

safety risk during installation.

Stringent environmental controls needed in

vaccine manufacturing

Aseptic processing is principally what is

employed to ensure assurance of sterility,

because some vaccines are not filterable or

cannot be sterilized by heat, gas or radiation.²

Axenic products (sterile except for the organism

of choice in the vaccine) must use aseptic

processing as well as environmental

controls/monitoring, in-situ

cleaning/sterilization of tanks and other

equipment, closed systems where possible and

even disposable single use systems.¹

Control measures of the environment include

differential pressures, air changes,

unidirectional air, closed manufacturing

processes wherever possible, qualification of

processes such as gowning, performance of media

fills, and control of environmental bioburden.

HEPA air filters should be qualified every six

months and smoke studies should be performed for

the highest controlled areas (Grade A) every

three years.

Material and personnel flows must be well

defined with traffic starting in Grade D areas,

into Grade C, then B and finally Grade A with

gowned personnel. Specific PPE for C and D

includes masks and gloves and usually something

like bulk-sterilized jumpsuits. There must be

limits to the numbers of people allowed in the

Aseptic Processing Area (APA) at any one time,

how long they may stay in the APA and control of

interventions (inherent/routine and corrective).

Gowning performance must be qualified before

personnel are allowed into the APA and they must

show adequate aseptic technique during media

fills prior to being allowed to fill aseptic

batches of product.

Bioburden of air, people, water, and gases must

be controlled. Samples sites, types of sampling

and sampling frequency should be defined in

Standard Operating Procedures (SOPs).

Levels/limits must be defined in SOPs along with

steps to be taken if levels are exceeded (e.g.,

performance of investigations) or trends are

detected.

Disinfectants may be qualified by outside

contract labs using coupon surfaces present in

the facility or by in-situ testing. Approved

disinfectants, their use-dilution and

appropriate dwell (contact) time must be listed

in SOPs.8

Do Moderna executives have faith in their

product?

Moderna executives sold stock as shares peaked

with positive announcements.

The timing of the transactions -- coupled with

concerns from some medical experts that Moderna

overstated the significance of its Phase 1

vaccine trial -- should be investigated by

authorities, former SEC officials told CNN

Business.

"The confluence creates an appearance, which may

be inaccurate, that people were in a rush to

take advantage of an early positive trial in

what is often a long and tortured development of

a new drug," Harvey Pitt, the former chairman of

the Securities and Exchange Commission, said in

an interview.

Pitt, who led the SEC from 2001 to 2003, called

the timing of the share sales by Moderna and its

leading shareholder "highly problematic." He

suggested authorities issue subpoenas for

emails, memos and other documents that can shed

light on the share sales.

Fauci defends comments relative to a vaccine

within 18 months

Dr Anthony Fauci is optimistic about developing

a vaccine in the next 12 to 18 months but is

concerned how effective the vaccine may be. He

addressed his thoughts on this in an interview

with STAT.

“The general trend on the part of the

pharmaceutical companies, because of the

enormous investment that goes into the

development of a vaccine, is that you don’t go

to the next step until you’re fairly certain

that the step you’re in is going to be

successful. The other thing is you don’t start

manufacturing anything until you have a pretty

good idea that you have a successful efficacy

signal. That protracts out the time frame. But

what we’re doing is something that’s called

developing “at risk.

What it means is that at the same time you’re

finishing your Phase 1 trial, you’re preparing

your Phase 3 trial sites, which is very

expensive, and then you’re starting to

manufacture the vaccine even before you know it

works. All that cuts months off.

We’re now completing the Phase 1 [with the

Moderna vaccine]. The initial data look very

promising from the neutralizing antibody

standpoint. And so, they’re planning to start

the Phase 3 in the first week or so of July. Not

only with the Moderna vaccine, but also very

likely with the AstraZeneca

vaccine.

And then as we get later into the summer, we’ll

get the Johnson & Johnson in clinical trials.

You need a few months at least of having

vaccinated individuals getting exposed. So,

let’s say it’s July, August, September, October.

By November, you should have an efficacy signal.

If you do and you’re already manufacturing

doses, by December and January, if you’re lucky

and if in fact it is effective, you can have a

significant number of doses available by the end

of the year, the beginning of 2021. So, I think

it’s aspirational, but it’s certainly doable.

The only thing that’s the big unknown to me is

that, is it going to be effective? I think we

could do it within the time frame that I’ve

outlined. But there’s no guarantee that it’s

going to be effective.”

Challenge to prioritize COVID over other

clinical trials

How much impact will COVID have both near term

and long term on clinical trials for other

products?

This question was addressed in Cell &

Gene by

Angela De Martini, Dean Lockhead, Leandra

Plappert, and Elizabeth Rountree, of Charles

River Associates (CRA).

As companies learn to adapt and consider

implementing new strategies to keep clinical

trials on track, in many cases the only option

is to temporarily pause or delay development

programs. For example, Provention Bio recently

paused a Phase 3 trial in type 1 diabetes and

Iveric Bio temporarily stopped a pivotal trial

in geographic atrophy.3,4 But these

decisions are not limited to smaller companies.

Eli Lilly, Bristol-Myers Squibb, and Pfizer have

announced pauses or delays in multiple

development programs.5,6

While consensus is that the impact of COVID-19

on clinical trials will be far-reaching, our

analysis suggests that the level and duration of

this impact will be especially severe in studies

that have the following characteristics:

·

Enrolled vulnerable populations, including the

elderly, the immunocompromised, and patients

with pulmonary conditions (e.g., COPD)

·

Have primary or secondary endpoints that require

in-person visits or hospital infrastructure and

equipment (e.g., CT and PET scans) for

assessment

·

Involve indications with minor safety or quality

of life implications for patients (e.g.,

“lifestyle drugs”) and indications where a

patient’s environment has a significant impact

on therapeutic success (e.g., psychiatric, and

neurological indications)

·

Are currently in the patient recruitment stage

or are in Phase 1 with healthy volunteers

·

Have trial sites located within hospitals or

tertiary academic centers and in areas with high

COVID-19 case density, potentially reducing the

availability of staff to perform required

activities and increasing the risk of adverse

events and patient loss

·

Are evaluating immunosuppressive therapies or

therapies that require complex and prolonged

hospital visits (e.g., CAR-T cell and gene

therapies)

·

Involve smaller patient populations where there

are minimal margins of statistical power or

people living with rare diseases (because

patient accrual is already difficult, and the

pandemic increases the risk for patient loss)

While most regulatory agencies have stated an

intention to be flexible during these

unprecedented times, it is critical that drug

developers continue to monitor their risk

diligently and develop contingency plans to

adapt and respond to factors that affect their

clinical development programs. Sponsors will

need to balance patient safety, trial integrity,

and statistical power considerations against

funding and revenue issues on a trial-by-trial

basis. In addition to reevaluating clinical

development plans, companies may need to

reassess their assumptions around pricing and

revenue as well as the competitive landscape for

both their pipeline and in-line products.

There will not be a one-size-fits-all solution

for the many short- and long-term challenges

caused by COVID-19, but companies that are

willing and able to rapidly adapt are likely to

have the strongest chances for success.

https://www.cellandgene.com/doc/covid-clinical-trials-understanding-the-long-term-impact-0001

“May be effective” is not the criterion for

widespread vaccine use

Steven Joffe and Holly Fernandez Lynch of the

University of Pennsylvania Perelman School of

Medicine addressed the wisdom of accelerated

vaccine use in a Washington post editorial.

The potential benefits of emergency

authorization for a therapeutic drug are clear:

seriously ill patients get access to a therapy

that might help them. But there are downsides.

The drug might be unsafe or ineffective.

Availability of the drug also might divert

patients from trying more promising alternatives

or participating

in clinical trials needed

to demonstrate what actually works.

The trade-offs are very different when

considering emergency authorization for products

intended to prevent rather than treat disease.

The FDA has used this pathway for a vaccine only

once, in 2005, allowing a decades-old vaccine to

be used to prevent anthrax in

a bioweapon attack.

When the agency authorized emergency use of

other preventive drugs, as it did for anthrax in

2008 and H1N1 influenza

in 2009, the drugs were already FDA-approved.

Emergency authorization of a new vaccine for the

novel coronavirus would be unprecedented.

Emergency treatments may be given to thousands,

or tens of thousands, of very sick patients. But

a vaccine could reach millions — even tens of

millions or hundreds of millions — of healthy

people. Because vaccine recipients are not sick,

their potential to benefit stands to be much

less than that of seriously ill patients given a

drug, especially in light of the effectiveness

of alternatives such as physical distancing and

good hygiene. If data ultimately shows that

vaccine effectiveness is limited while the risks

are substantial, harms to millions of uninfected

individuals could

be enormous.

False reassurance from a flawed vaccine might

also worsen the epidemic, setting back progress.

Public trust in

vaccines is another critical consideration.

Already, the anti-vaccine movement has begun to sow

doubt about

a coronavirus vaccine. Even if an option

ultimately proves to be safe and effective, it

won’t do much good if many people refuse

it.

And if a covid-19 vaccine causes harm, efforts

to counter other vaccine-preventable diseases

may be set back as well.

For all these reasons, the FDA must

apply rigorous standards when

considering whether to authorize a coronavirus

vaccine. The agency must wait until data from a

well-controlled trial demonstrates that a

vaccine is able to prevent covid-19

and that it is safe enough to give to millions

of people.

There is acute need for a vaccine that will

change the course of this pandemic and allow

normal economic and social activity to resume.

Experience suggests that the FDA will be under

intense pressure to authorize emergency use of

the first plausible candidate, even if data

supporting its benefits are thin. But when it

comes to vaccines, “may be effective” is not

good enough.

https://www.washingtonpost.com/opinions/2020/06/02/fda-should-not-rush-covid-19-vaccine/

Pfizer says vaccine likely available by end of

October

Pfizer

CEO, Albert Bourla, believes they will have a

COVID-19 vaccine ready by the end of October.

The company is currently in the clinical trial

stage of

development, crafting their vaccine alongside

Germany's BioNtech. The companies, whose project

relies on messenger RNA technology never used in

an approved vaccine, dosed the first humans in

Germany earlier on in May, and hope to begin a

US trial soon, pending regulators' blessing.

If things go well, and the stars are aligned, we

will have enough evidence of safety and efficacy

so that we can... have a vaccine around the end

of October," said Bourla, according to AFP.

Pfizer, BioNtech and other companies are racing

to develop a vaccine, since there are currently

no approved treatments and only mixed results of

medicines under study against the virus.

Pfizer aims to make 10-20 million doses of the coronavirus

vaccine by

the end of 2020 for emergency use should it pass

tests, the US drug maker's head of vaccines

announced in May.